Auxiliary monitoring system and method for unattended mode pipe gallery tunnel

A monitoring system and pipe gallery technology, which is applied in tunnels, mines/tunnel ventilation, pump control, etc., can solve the problems of heavy inspection workload, high dependence on operation and maintenance personnel, and inability to be timely and accurate, and achieve wide application value , Reduce the difficulty of operation and maintenance, improve the effect of speed and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

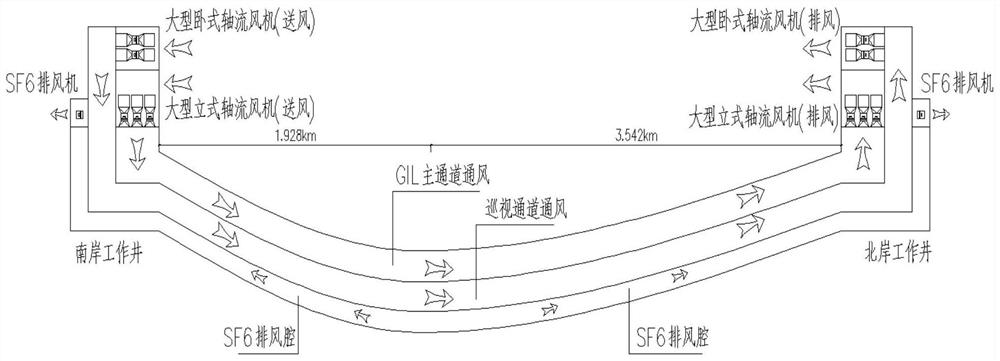

[0036] refer to figure 1 As shown, this embodiment introduces an auxiliary monitoring system for a pipe gallery tunnel, including a control unit; the pipe gallery tunnel includes an SF6 exhaust channel, a patrol channel and a main channel extending along the length of the pipe gallery tunnel respectively; There are ventilation valves; both ends of the inspection channel and the main channel are provided with air supply and exhaust fans respectively, and both ends of the SF6 exhaust channel are respectively provided with SF6 exhaust fans; the inspection channel and the main channel are provided with multiple SF6 along the extension direction of the channel Sensor, temperature and humidity sensor, harmful gas sensor and oxygen sensor; the output ends of the SF6 sensor, temperature and humidity sensor, harmful gas sensor and oxygen sensor, and the control ends of each ventilation valve, blower and exhaust fan are respectively connected to the control unit.

[0037] The above-ment...

Embodiment 2

[0043] Based on the auxiliary monitoring system of Embodiment 1, the monitoring method of this embodiment includes:

[0044] Obtain the detection data of SF6 sensor and temperature and humidity sensor in real time, as well as the switch status data of each fan and ventilation valve;

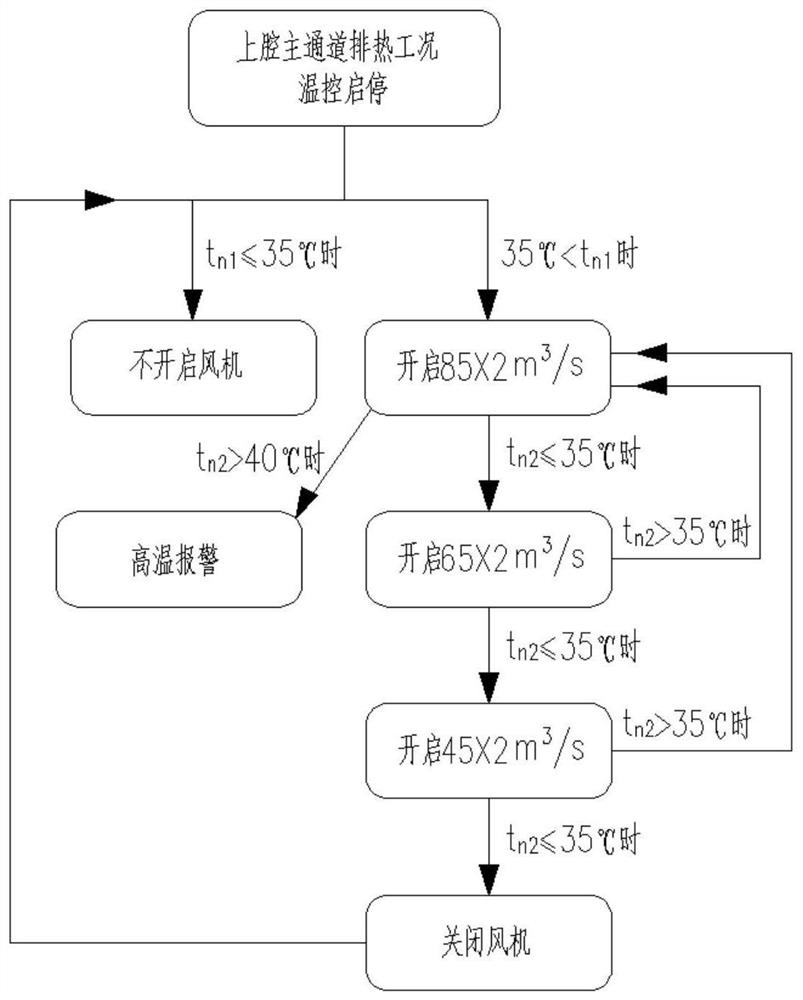

[0045] According to the acquired detection data, the working conditions in the tunnel of the pipe gallery are judged, and the working conditions include SF6 warning working conditions, SF6 warning working conditions and other gas accident working conditions that are preset according to the SF6 concentration and corresponding to different concentrations, and Pre-set temperature and humidity conditions to be exhausted;

[0046] According to the judgment results of the working conditions, according to the preset fan and valve control strategy, control the switches of different fans or valves at different positions in the tunnel, so that the temperature in the tunnel meets the preset temperature requ...

Embodiment 2-1

[0056] Based on Embodiment 2, this embodiment specifically introduces a monitoring method for a pipe gallery tunnel auxiliary monitoring system, including the following contents:

[0057] Step 1: Collect the status data of key equipment such as fans and ventilation valves: including vertical, horizontal, SF6 fans, and all open and closed states in the pipe gallery; at the same time, fans and ventilation valves can be opened through communication or hardware nodes. and closed remote control, which can remotely adjust the fan air volume through communication with the inverter;

[0058] Step 2: Collect data of various types of sensors such as gas, temperature and humidity installed inside the pipe gallery: including SF6, CH4, CO, H2S and oxygen and other gas sensor data, temperature and humidity sensors, wind speed and pressure sensors, etc. inside the pipe gallery;

[0059] Step 3: The collected data is classified and displayed in a centralized manner, and the validity of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com