Wedge-shaped pressure expansion type pipeline plugging device

A technology for plugging devices and pipelines, which is applied in the direction of cable entry sealing devices, pipes, pipes/pipe joints/pipe fittings, etc. It can solve the problems of low sealing degree, complicated installation process, poor durability, etc., and achieves strong plugging pressure bearing capacity , clear working principle and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

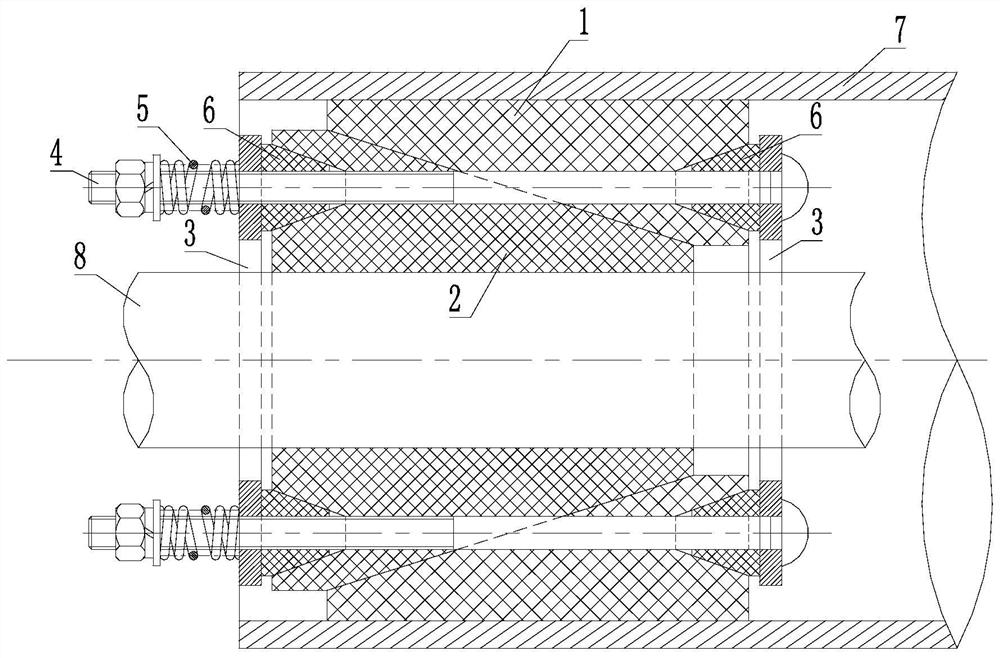

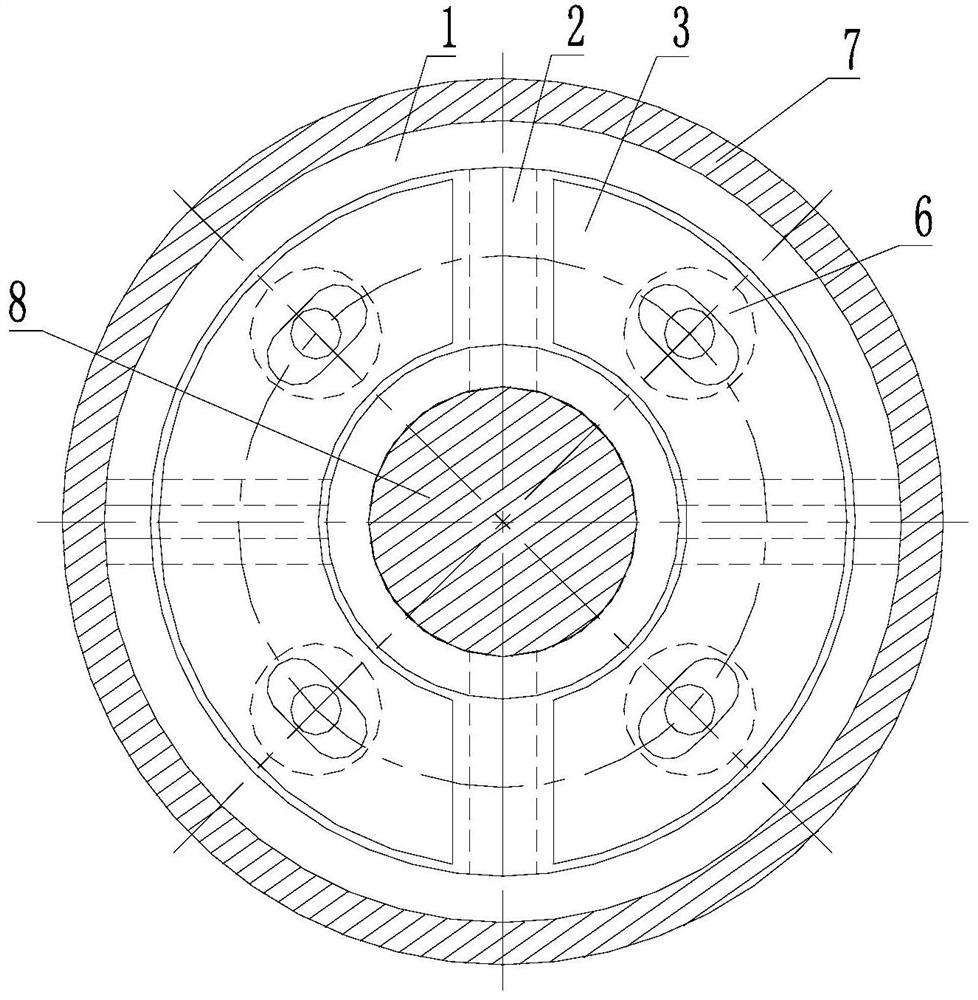

[0033] Such as figure 1 and figure 2 As shown, a wedge-shaped expansion pipeline sealing device of the present invention includes a sealing device installed in the inner hole 7 of a structure, and a cable or a pipeline 8 passes through the sealing device, and the sealing device includes at least one Outer wedge 1 and at least one inner wedge 2, at least one outer wedge 1 and at least one inner wedge 2 are spliced with each other, and are squeezed toward the middle through the locking connector to generate relative longitudinal displacement, and at the same time generate radial relative The pressure expands, so that the inner wedge and the outer wedge are squeezed and sealed with the perforation 7 and the pipeline 8 respectively. .

[0034] In this embodiment, the inner and outer wedges are divided into two lobes according to the circular geometric center, and the joint surface of the dividing line is a shape such as a rectangle or a trapezoid that meshes with each other. ...

Embodiment 2

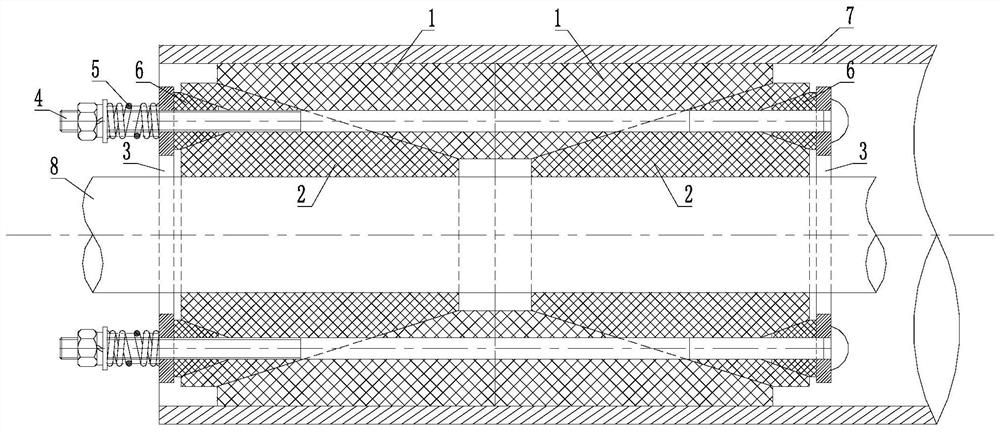

[0044] This implementation is as image 3 As shown, the outer wedge of the device can be designed into a square according to the shape of the perforation, and the outer wedge of the square structure is divided into four petals according to the vertical and horizontal geometric centers in the circular direction, and other designs are the same.

[0045] For plugging with high sealing requirements and high pressure, the "back-to-back" series type can be used, which can double the plugging performance and pressure bearing capacity, and the working principle is the same.

[0046] In the present invention, by tightening the connecting screws and nuts, the front and rear side connecting pieces generate uniform extrusion force inward and act on the inner and outer wedges at the same time, and the two layers of wedges produce inward longitudinal displacement. The action of the inner and outer wedges produces radial relative radial slip at the same time, that is, the outer wedge expands...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com