Coal pile density measuring method

A technology of density measurement and density, which is applied in the direction of measuring devices, specific gravity measurement, instruments, etc., can solve the problems of inability to measure coal pile density, inability to obtain accurate coal storage, inaccurate measurement, etc., and achieve low labor intensity and measurement Convenience and logical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

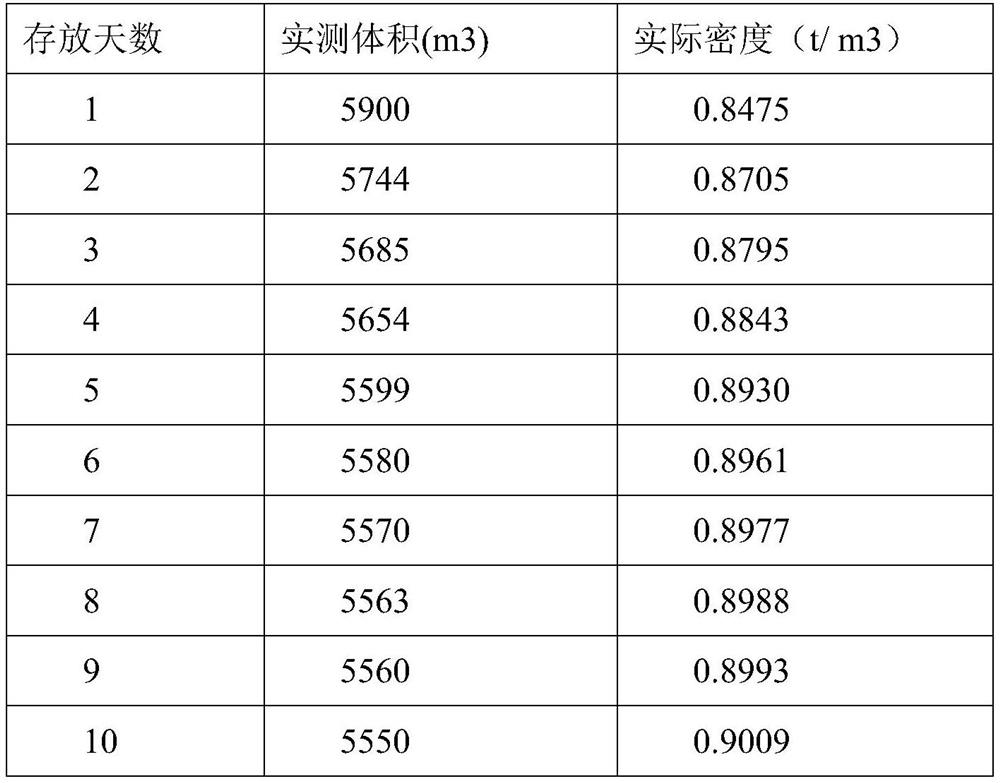

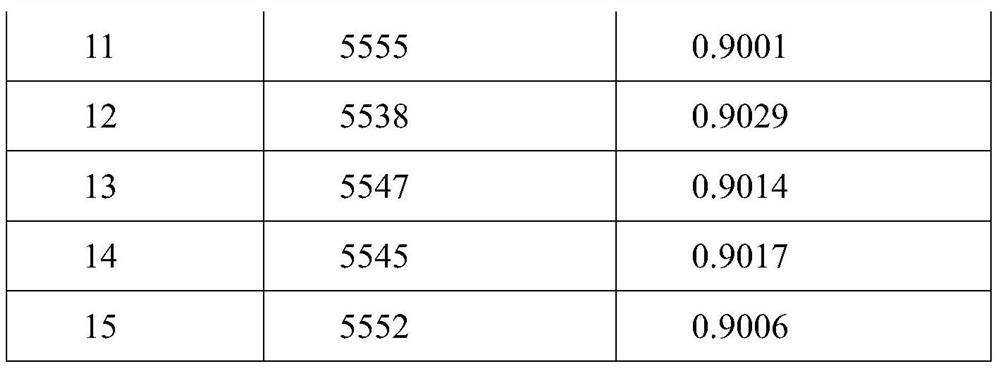

Examples

Embodiment Construction

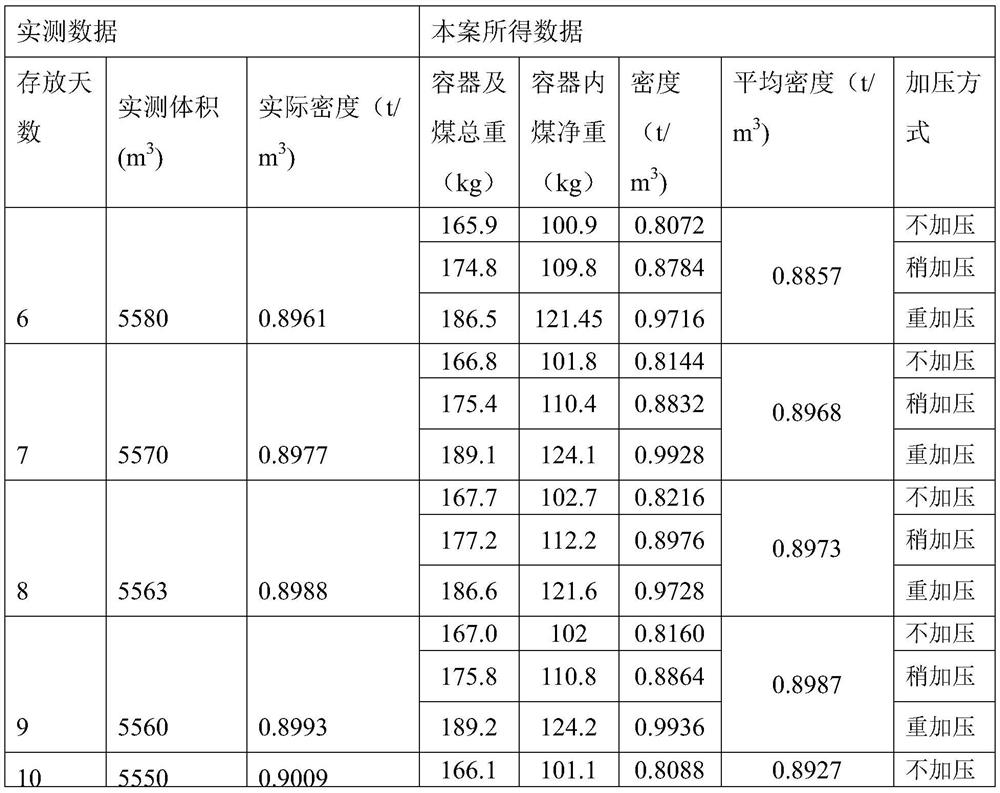

[0026] In order to clearly illustrate the technical features of this patent, the following describes this patent in detail through specific implementation methods.

[0027] The present invention measures the coal bulk density by means of a measuring device, the measuring device includes an electronic scale, a density box, a gland and a lifting device, the density box is provided with a cavity with an open top, and the gland and the lifting device It can be lifted to a specified height under the action of the lifting device and then move downward; the lifting device can be a manual lifting device with a cable and a fixed pulley, or an automatic lifting device with a cable and a hoist; or Slightly pressurize and repressurize the coal by applying pressure to the gland with pressure equipment such as hydraulic pressure or air pressure. pressure.

[0028] The measuring method of described coal bulk density is carried out as follows:

[0029] S1, measurement without pressure;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com