Gasket mounting equipment and gasket mounting method for motor with reversing mechanism

A technology of reversing mechanism and installation equipment, which is applied to electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of low success rate and low assembly efficiency of insulating gaskets, so as to improve efficiency and improve the success rate of blanking. , Improve the effect of feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

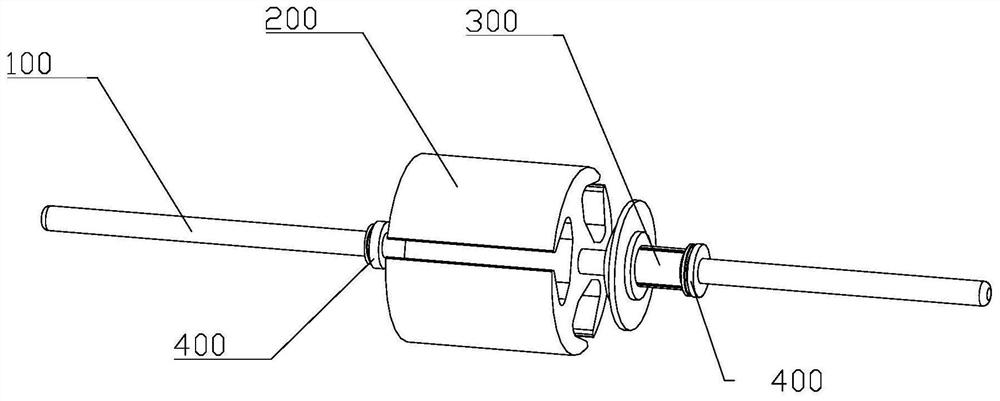

[0027] like figure 1 The shown motor rotor with commutation mechanism mainly includes a rotating shaft 100, an iron core 200, a commutator 300 and an insulating gasket 400. A coil is wound on the iron core 200, the commutator 300 corresponds to the brush, and the insulating gasket 400 is clamped on the rotating shaft 100, and the insulating gasket 400 is used to limit the axial position of the rotating shaft 100 in the stator.

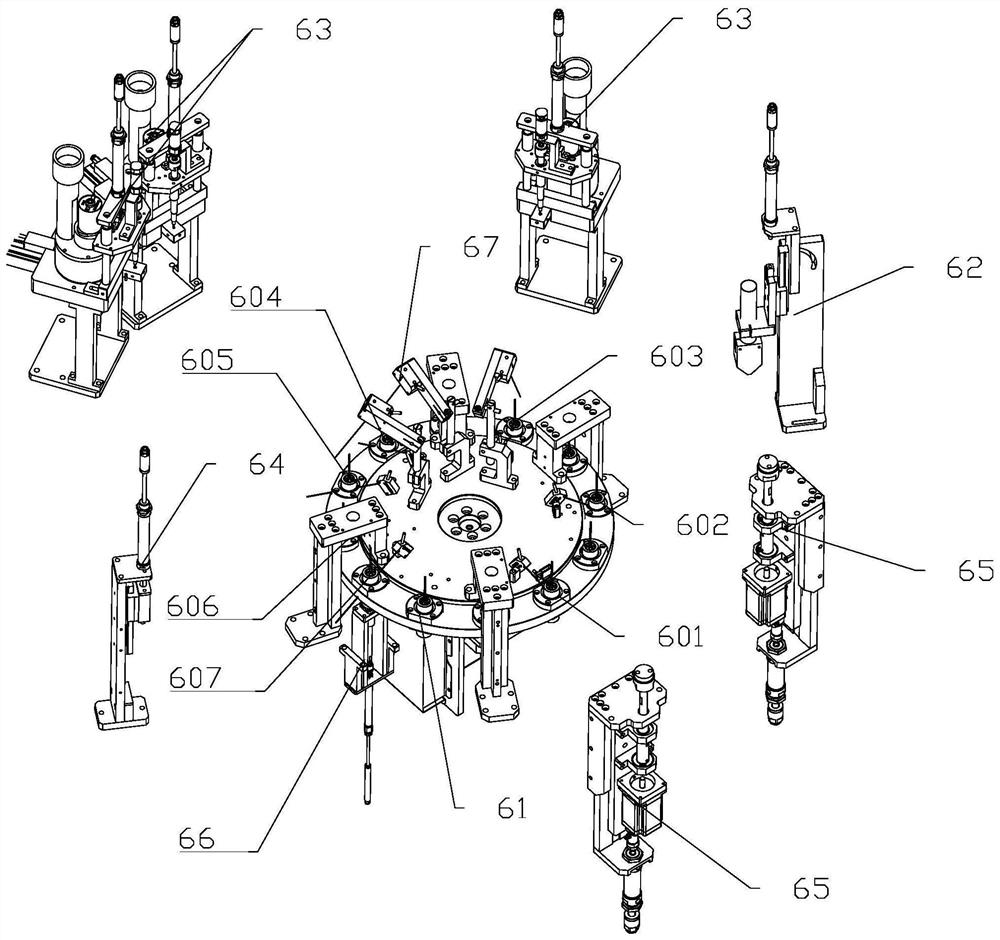

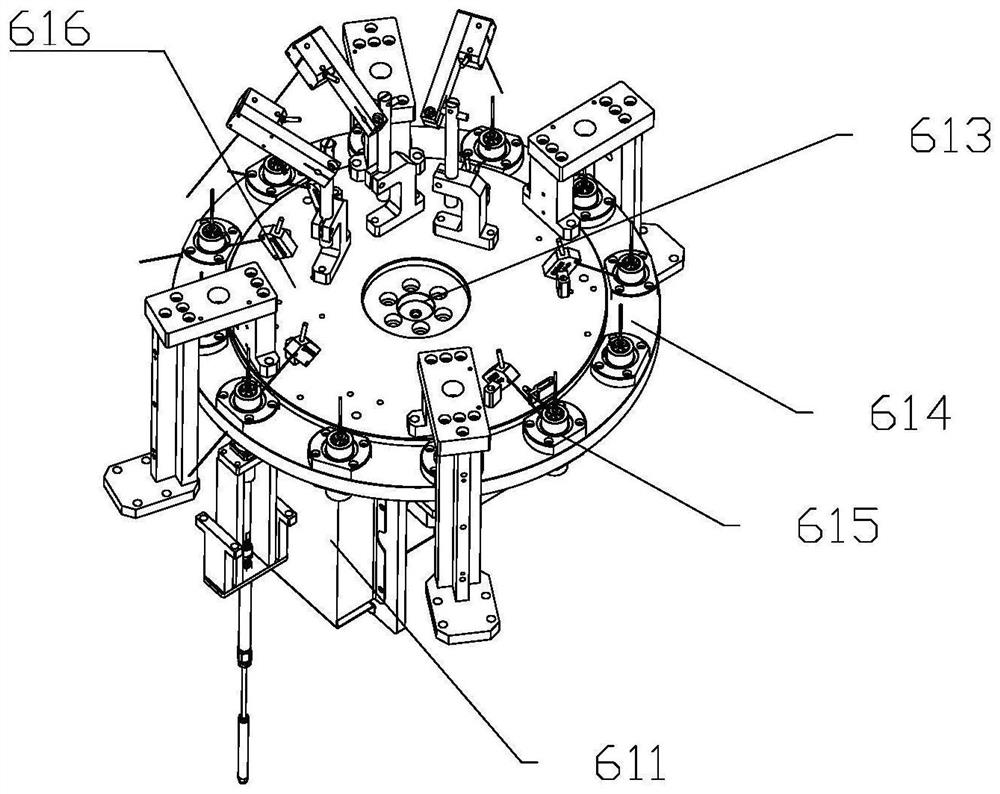

[0028] like Figure 2-9 As shown, a gasket installation device with a motor with a reversing mechanism includes a rotating fixture 61, an oil point device 62, an insulating gasket feeding device 63 and an insulating gasket pressing device 64; a circumference of the rotating fixture 61 is provided with Feeding station 601, oiling station 602, first insulating gasket loading station 603, second insulating gasket loading station 604, third insulating gasket loading station 605, pressing station 606 and discharging Station 607; the oil spotting device 62...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com