Combustion heat supply mechanism in reforming hydrogen production device

A reforming hydrogen production device, combustion heating technology, applied in the fields of hydrogen, inorganic chemistry, hydrogen/synthesis gas production, etc., can solve the problem of poor gas and air preheating effect, limited space in the reforming reaction zone, and poor heating uniformity and other problems, to achieve the effect of increasing space, stable ion current detection, and reducing heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

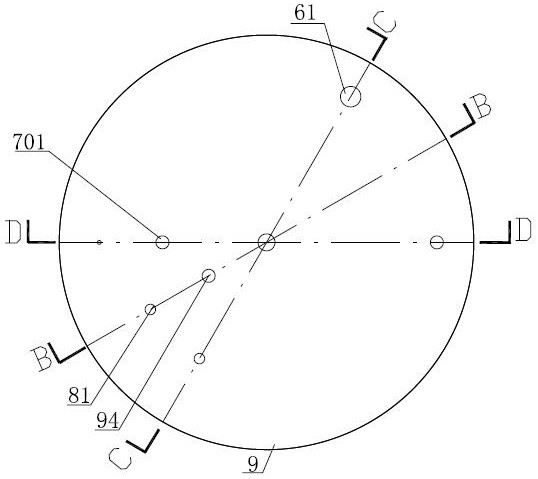

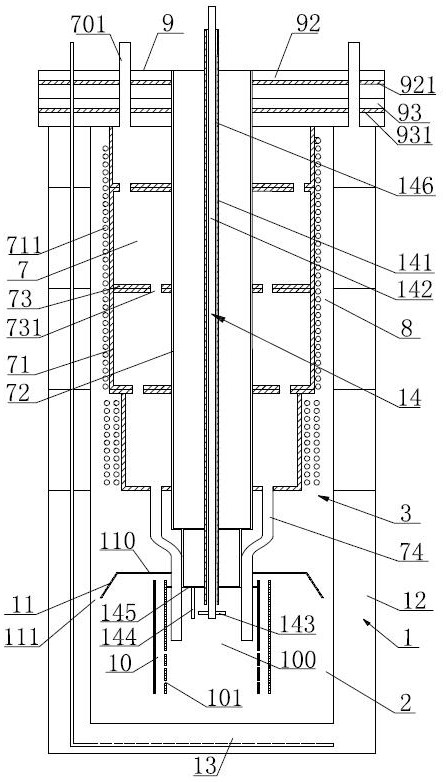

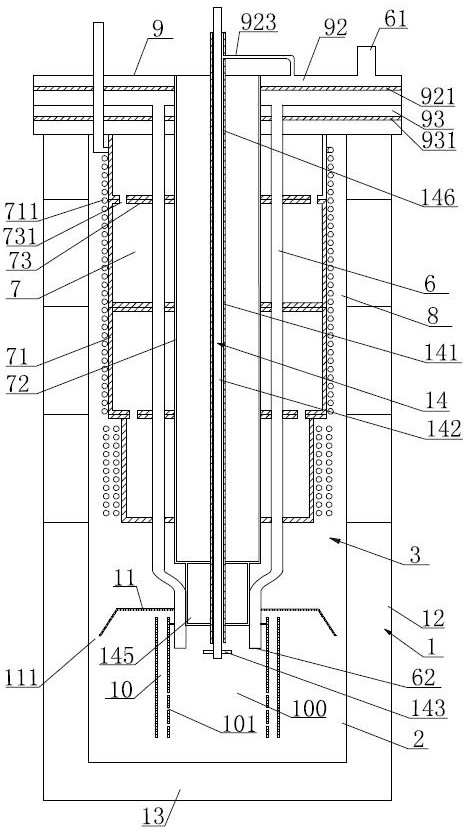

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the combustion heat supply mechanism in the reforming hydrogen production device includes: a cavity 3 formed around the reaction chamber 1, the top of the cavity 3 is closed, and the bottom of the cavity 3 is the furnace 2. In order to increase the heat exchange area, To improve the heat exchange effect, the inner wall of the furnace 2 is serrated, such as Figure 6 shown. The cavity above the furnace 2 is provided with a burner 14 , a gas passage, an air passage 7 , and a waste gas discharge passage 8 . The furnace 2 is provided with several return pipes 10, there is a gap between the lower end of the return pipe 10 and the bottom of the furnace 2, the return pipes 10 are arranged at intervals in the circumferential direction, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com