Preparation method of nanoparticles and application thereof

A nanoparticle and particle size technology, applied in grain processing, etc., can solve problems such as unstable shelf life of finished products, complex nanoparticle process, etc., achieve excellent anti-sag ability, wide application range, and solve unstable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

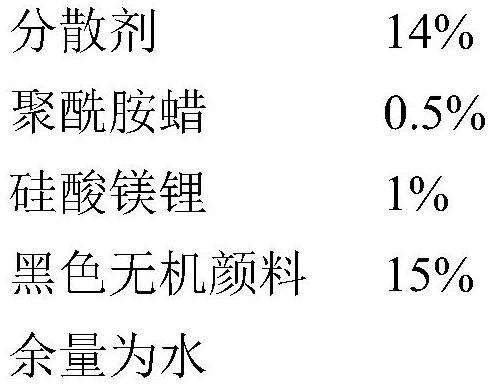

[0033] The user operates according to a method for preparing nanoparticles proposed by the present invention, wherein the user uses an inorganic black pigment as the raw material of this embodiment, first, prepares the following components in weight percentages:

[0034]

[0035] In this example, the dispersant used is Tego 740 water-based dispersant from Germany, the polyamide wax is Changxing Xiehe, and the lithium magnesium silicate is Guangzhou Shengxin Chemical. There are many types of water-based pigments that can be used, including domestic The imported ones can also be used.

[0036] Then follow the steps below:

[0037] (1) Coarse grinding: use a dispersion cylinder for grinding,

[0038] A. Put 14Kg dispersant and 45Kg water into the dispersing tank and stir for 20 minutes. In this embodiment, German Digo 740 water-based dispersant is used. The dispersant has electrostatic shielding effect and steric hindrance effect, which can prevent agglomeration , to maintai...

Embodiment 2

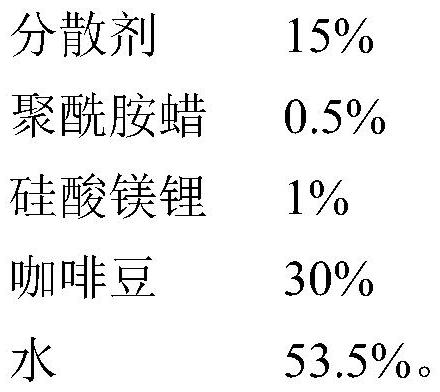

[0058] The preparation method of embodiment 2 is identical with embodiment 1, and difference is only in the present embodiment, and the raw material that we adopt is cocoa powder, and, the weight proportion of each component, altogether 20Kg, is as follows:

[0059]

[0060] We measured d(0.1) as 0.035um, d(0.5) as 0.068um, and d(0.9) as 0.098um by Malvern particle size analyzer (model: MASTERSIZER 2000).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com