Bending device for bending machine

A bending device and bending machine technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of difficult precise control of bending angle, driving inertia error, etc., and achieve simple structure and eliminate driving inertia error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

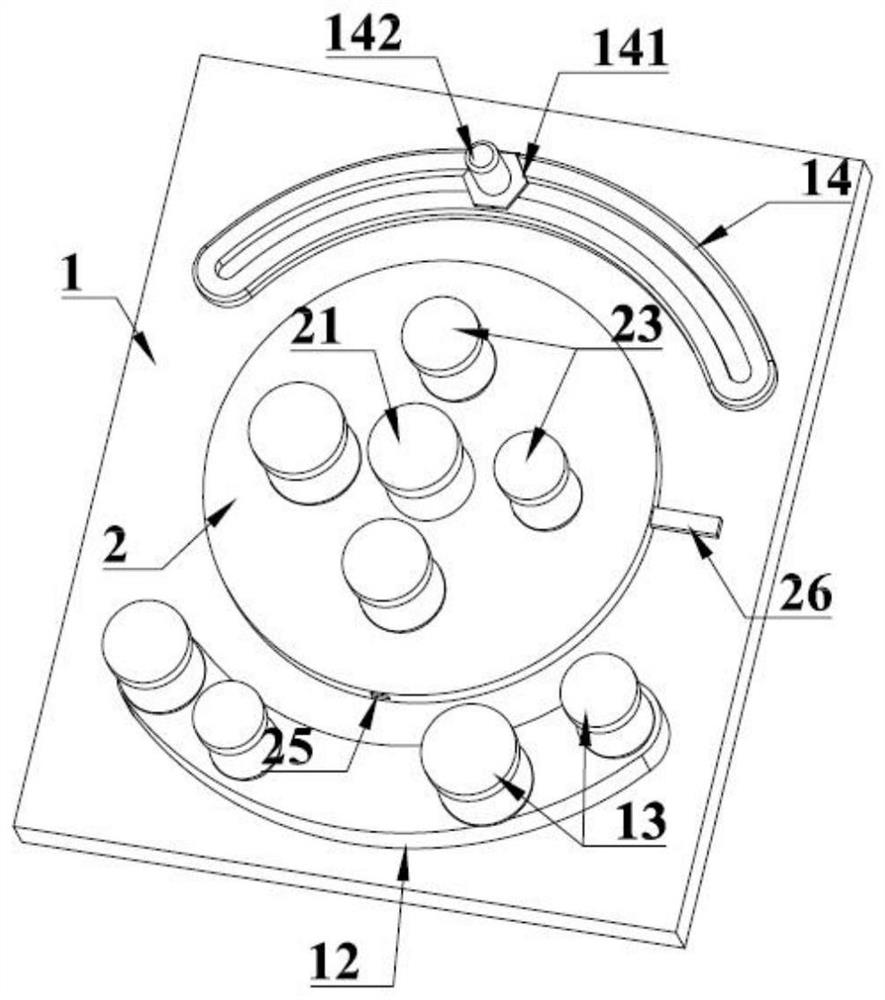

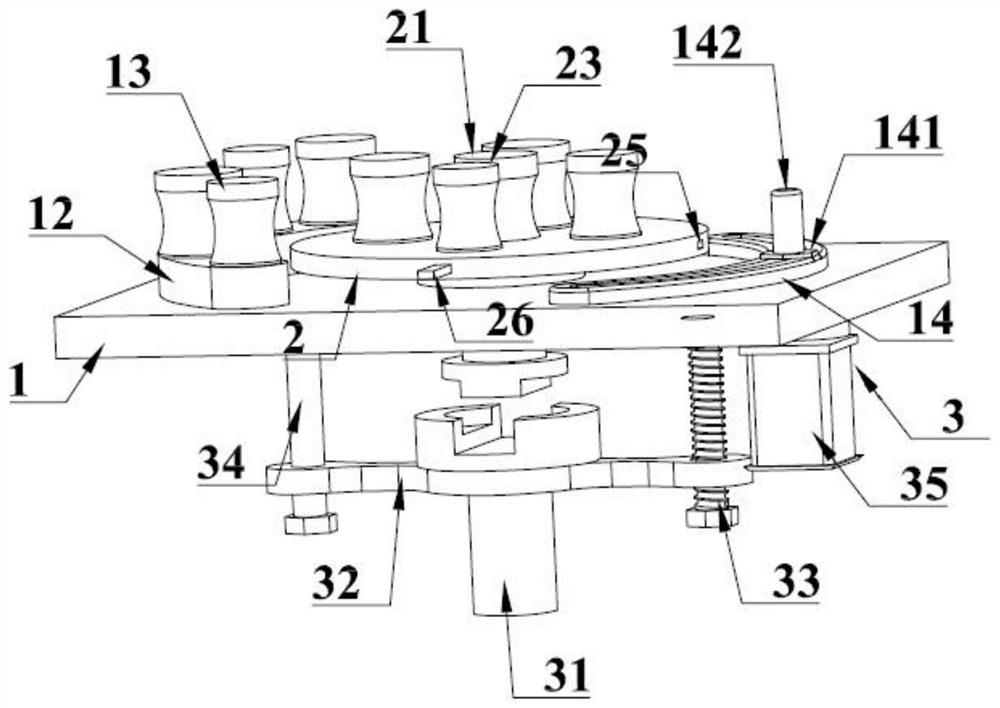

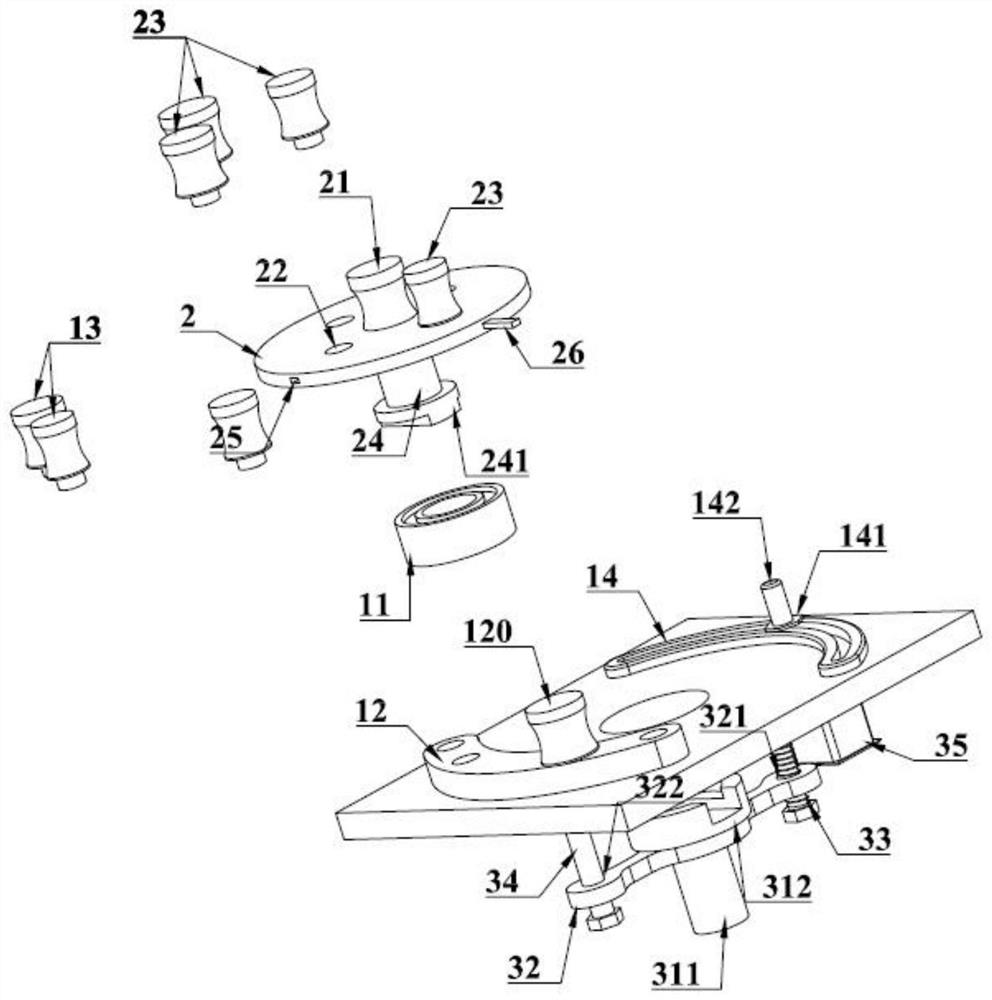

Image

Examples

Embodiment approach 2

[0028] like Figure 4 As shown, the lower surface of the fixture table 1 is provided with a protective cover 15, and the protective cover is provided with a mounting bearing and a transmission belt. The screw rod 33 is installed on the connecting bearing and passes through the protective cover 15. The stepping motor 35 is installed on the protective cover 15, the output shaft of the stepping motor 35 penetrates the protective cover 15, and is connected with the described screw mandrel 33 by the transmission belt. Other components and structures are as described in Embodiment 1, omitted.

[0029] like Figures 5 to 6 As shown, in specific use, connect the motor shaft sleeve 311 on the bending device with the main motor, and select the appropriate torsion shaft 23 according to the workpiece during operation, and place the part of the workpiece to be bent between the base shaft 21 and the torsion shaft 23 Then insert the retaining shaft 13 to fix it, adjust the position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com