Structural pipe prefabricating method

A prefabricated structure, steel plate technology, applied in the direction of manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problems of increasing operation risks, increasing operation procedures and equipment investment, and many procedures, and reducing the end mouth cutting process, The effect of improving the efficiency of construction production and simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

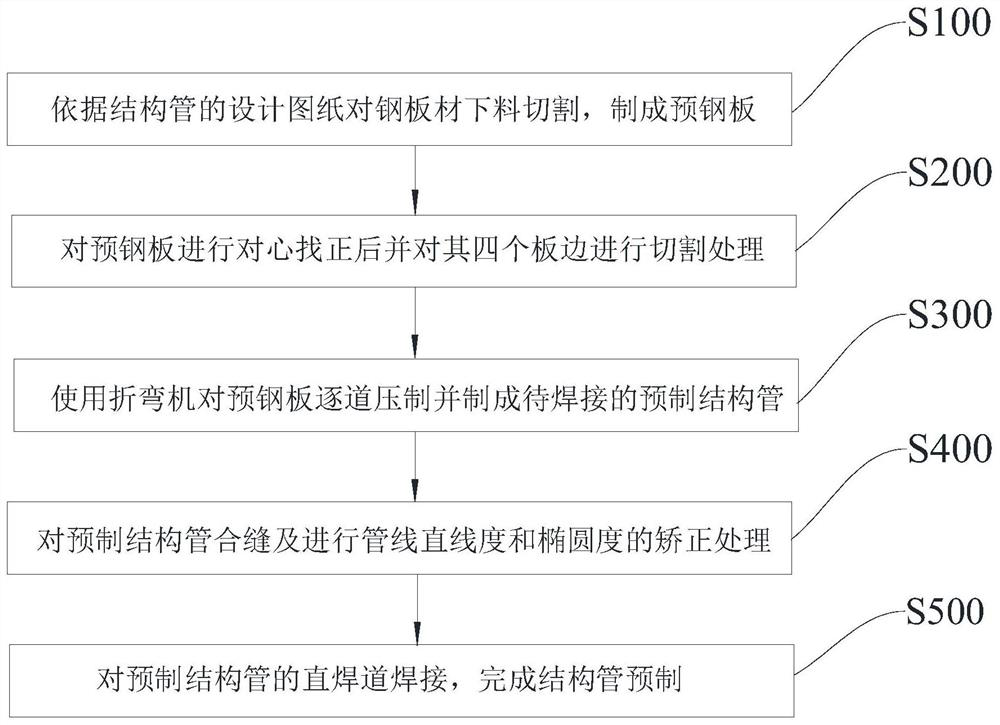

[0021] Such as Figure 1 to Figure 6 As shown, a structural tube prefabrication method includes the following steps:

[0022] S100, according to the design drawing of the specification and size of the structural pipe 1, the steel plate is blanked and cut to make a pre-steel plate 10;

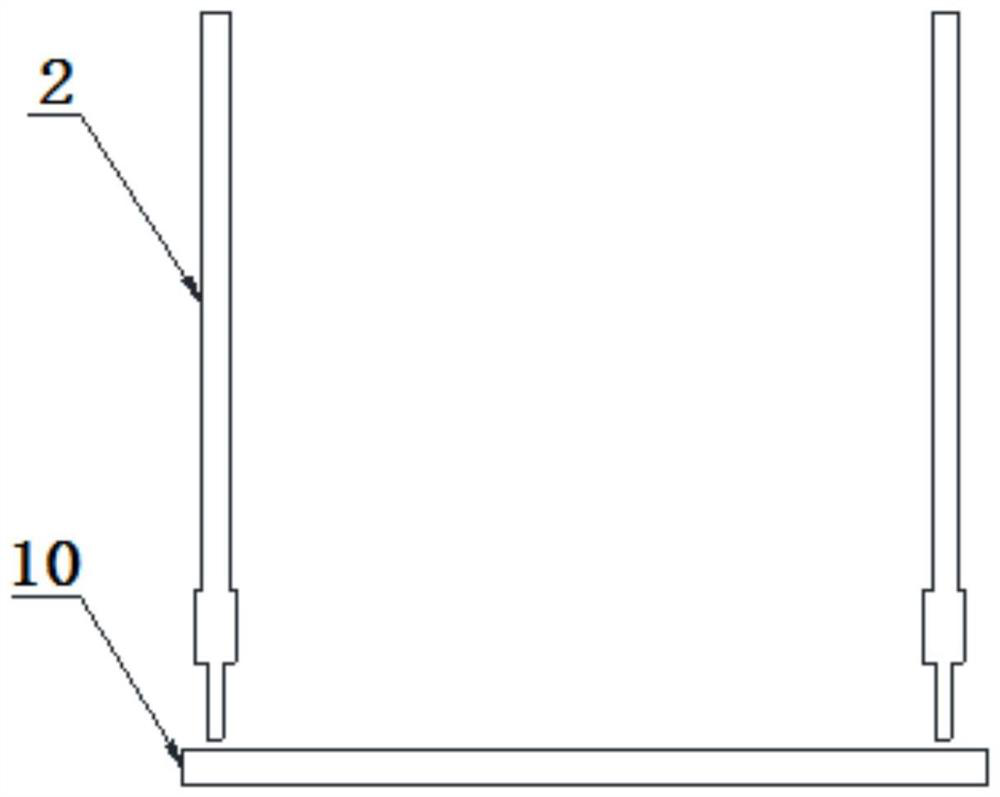

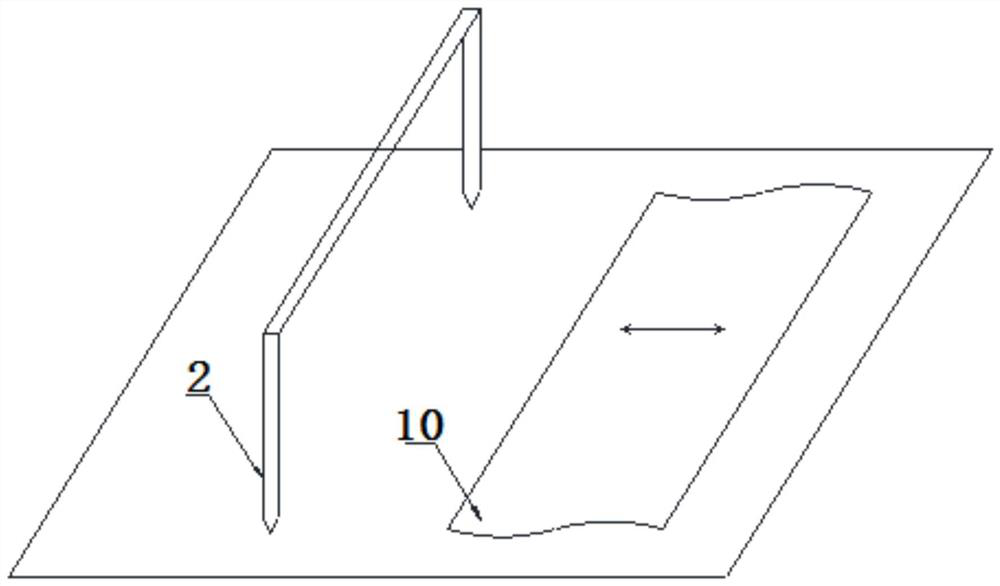

[0023] S200, after centering and aligning the pre-steel plate 10 in S100, cutting the four edges of the pre-steel plate 10, wherein the pre-steel plate 10 is hoisted and tiled on the data cutting frame for centering and alignment, and The four ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com