A kind of drilling device for metal plate processing that can quickly clean up debris

A drilling device and metal plate technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems that debris is easy to scratch the operator's fingers, affect the normal processing of the workpiece, and inconvenient to clean quickly, etc., to achieve Improve operational safety, facilitate collection, and avoid debris retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

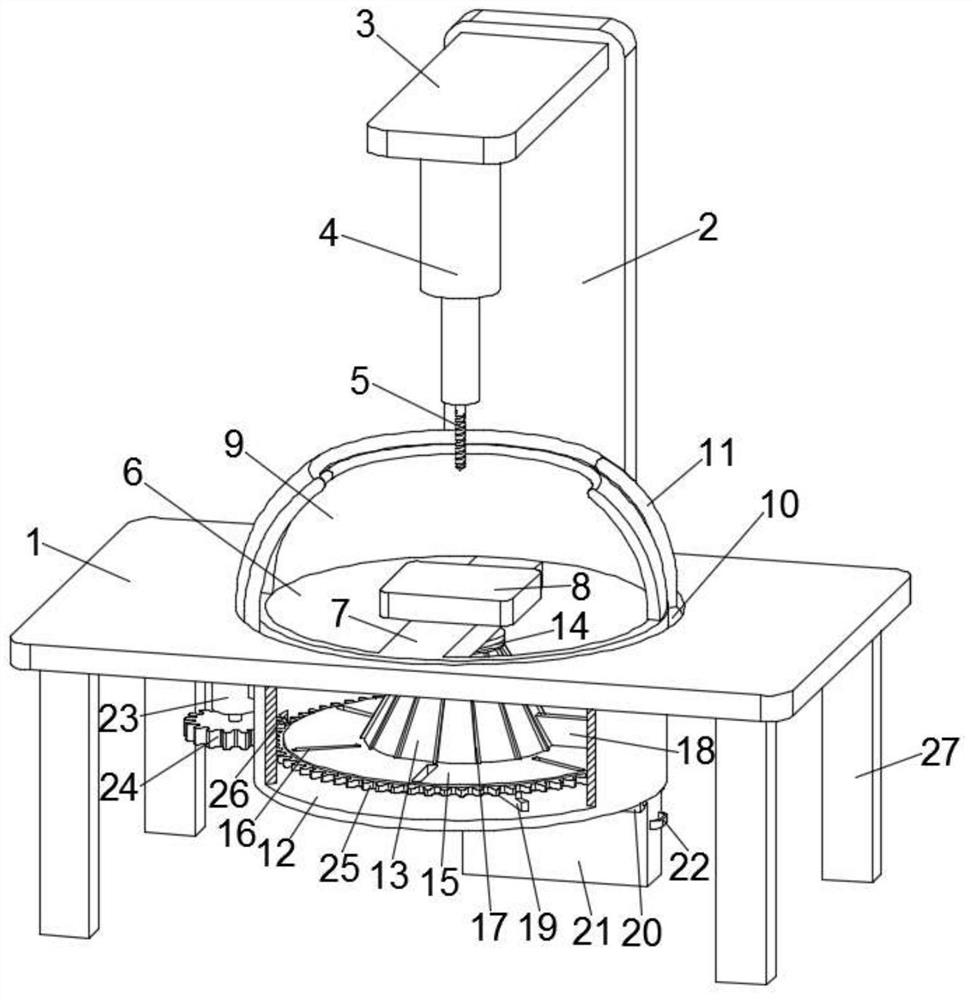

[0026] see figure 1 , a metal plate processing drilling device for quickly cleaning debris, including a workbench 1, a side plate 2 is fixed on the workbench 1, a top plate 3 is fixed on the top of the side plate 2, and the lower end surface of the top plate 3 is A drilling machine 4 is installed, and the bottom of the drilling machine 4 is provided with a drill bit 5;

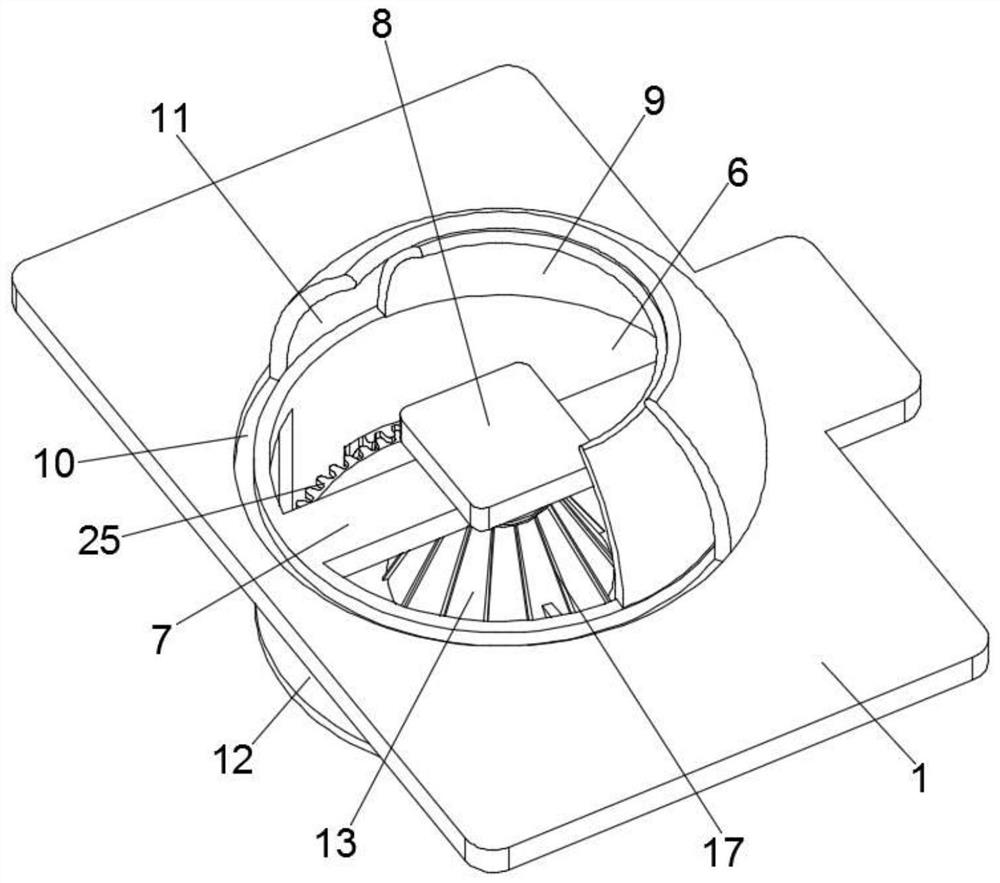

[0027] see figure 2 , the workbench 1 is provided with a circular hole 6, a horizontal plate 7 is horizontally arranged in the circular hole 6, a tooling platform 8 is fixed on the upper end surface of the horizontal plate 7, and the tooling platform 8 is located directly below the drill bit 5; The worktable 1 on the periphery of the circular hole 6 is provided with a fixed cover 9 and a movable cover 11 for blocking debris. rail 10, the movable cover 11 is slidably embedded in the annular slide rail 10;

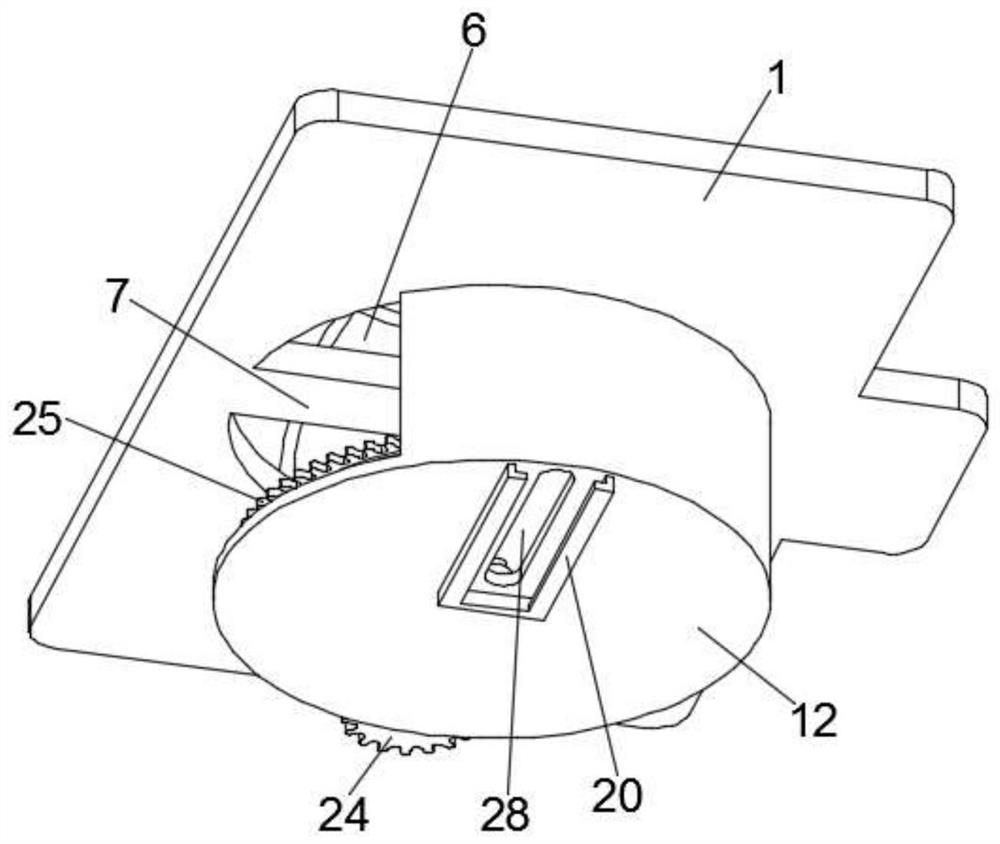

[0028] see image 3 , the bottom surface of the horizontal plate 7 is fixed with a round platform 13...

Embodiment 2

[0039] A drilling device for metal plate processing for quickly cleaning debris, including a workbench 1, a side plate 2 is fixed on the workbench 1, a top plate 3 is fixed on the top of the side plate 2, and the lower end of the top plate 3 is installed There is a drilling machine 4, and the bottom of the drilling machine 4 is provided with a drill bit 5;

[0040] A circular hole 6 is provided on the workbench 1, and a horizontal plate 7 is horizontally arranged in the circular hole 5, and a tooling platform 8 is fixed on the upper surface of the horizontal plate 7, and the tooling platform 8 is located directly below the drill bit 5; A fixed cover 9 and a movable cover 11 for blocking debris are provided on the workbench 1 around the circular hole 6, the fixed cover 9 is fixedly installed on the upper end surface of the workbench 1, and an annular slide rail is provided on the outside of the fixed cover 9 10, the movable cover 11 is slidably embedded in the annular slide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com