Intelligent stowage drag reduction system and method for ship navigation

A ship and stowage technology, applied in neural learning methods, ship safety, ships, etc., can solve problems such as heeling, swaying, accidents, poor adjustment ability, etc., and achieve the effect of improving the drag reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further understand the content, features and effects of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

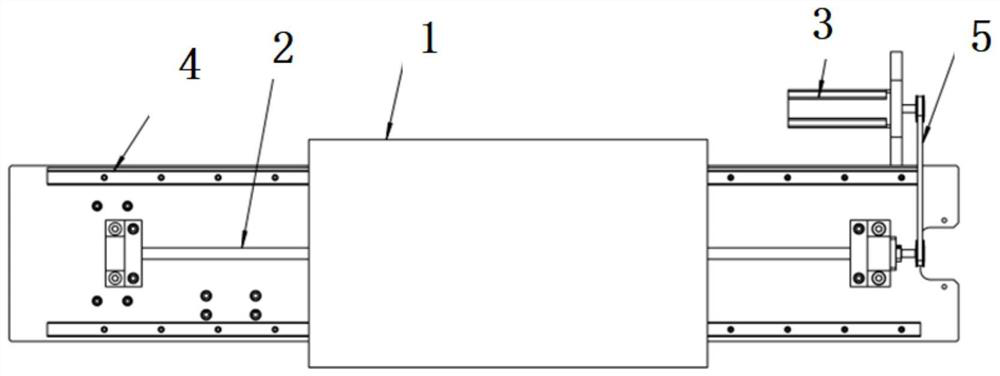

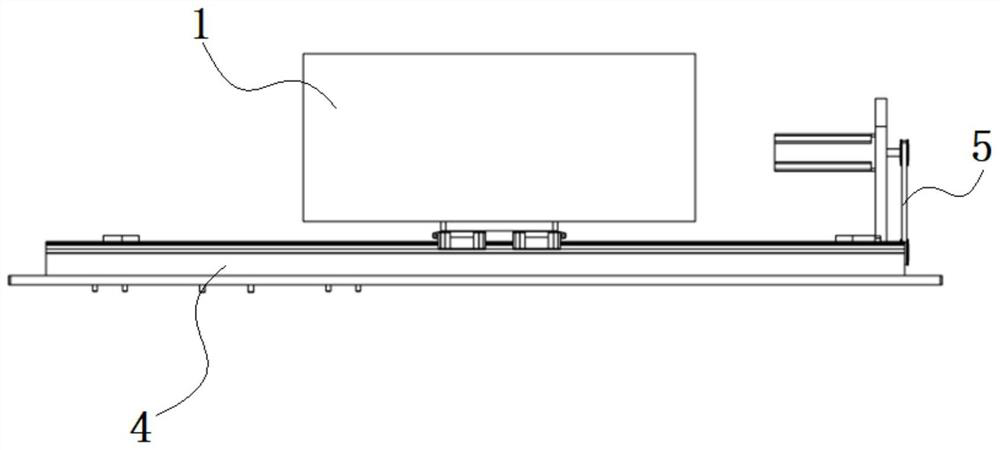

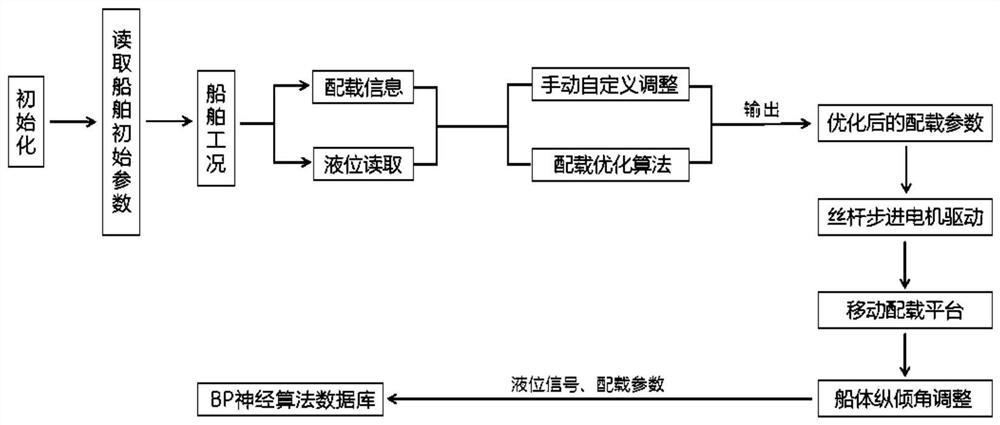

[0043] The intelligent stowage and drag reduction system for ship navigation of the present invention belongs to a kind of self-adaptive mobile stowage device independently developed. It is arranged on the longitudinal axis of the hull and is generally installed in the cargo warehouse. It refers to moving heavy objects according to the change of the inclination angle of the hull. To change the stowage of the hull. Its system consists of Figure 1-2 As shown, it includes a sliding platform mobile loading 1 (which can be in the form of a sliding platform loading container 1), a screw mandrel 2, a main controller, a servo motor 3, a slide rail 4, a conveyor belt 5, and a liquid level information reading device 6;

[0044] The slide rails 4 on both sides p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com