Drag reducer with pour-point depression function and preparation method of drag reducer

A technology of drag reducer and emulsifier, which is applied in the field of pour point depressant and drag reducer and its preparation, can solve the problems of losing light oil and affecting the normal transportation of crude oil, so as to reduce energy loss, increase flow rate, and reduce energy loss. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

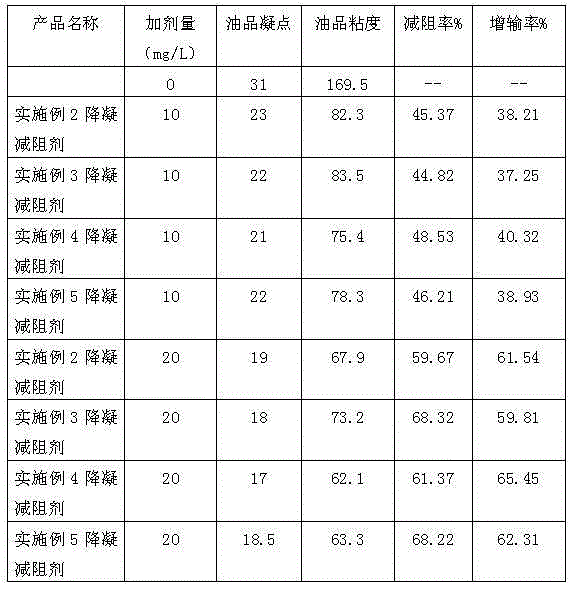

Examples

Embodiment 1

[0024] A pour point and drag reducing agent, composed of the following components in parts by weight:

[0025] 147-150 parts of 1-butene;

[0026] 180-185 parts of vinyl acetate;

[0027] Titanium tetrachloride-triethylaluminum 0.5-1 part;

[0028] 570-575 parts of n-butanol;

[0029] Emulsifier OP-1090-100 parts.

[0030] A preparation method of the pour point and drag reducing agent is carried out according to the following steps:

[0031] Step 1, purging the stainless steel reaction vessel with nitrogen, then sequentially adding 147-150 parts of 1-butene, 180-185 parts of vinyl acetate and 0.5-1 part of titanium tetrachloride-triethyl Aluminum-based catalyst, sealed and placed in a 0°C low-temperature reaction container to react at 0°C for 3 to 6 days;

[0032] Step 2: Grind the product after the reaction in step 1 into powder in an environment below -30°C, and add 570-575 parts of n-butanol and 90-100 parts of emulsifier OP-10 to the powder to prepare The product tha...

Embodiment 2

[0037] The pour point and drag reducing agent provided in this example is prepared according to the amount of the following raw material components:

[0038] Step 1, purging the stainless steel reaction vessel with nitrogen, then adding 147 parts of 1-butene, 185 parts of vinyl acetate and 1 part of titanium tetrachloride-triethylaluminum catalyst in this reaction vessel successively, after sealing Put it into a low-temperature reaction container at 0°C, and let it react at 0°C for 6 days;

[0039] Step 2: Grind the product after the reaction in step 1 into a powder in an environment of -30°C, and add 575 parts of n-butanol and 100 parts of emulsifier OP-10 to the powder to make a white suspension The product is pour point depressant and drag reducer.

Embodiment 3

[0041] The pour point and drag reducing agent provided in this example is prepared according to the amount of the following raw material components:

[0042] Step 1, purging the stainless steel reaction vessel with nitrogen, then adding 150 parts of 1-butene, 180 parts of vinyl acetate and 0.5 part of titanium tetrachloride-triethylaluminum catalyst to the reaction vessel successively, after sealing Put it into a low-temperature reaction container at 0°C, and let it react at 0°C for 3 days;

[0043] Step 2: Grind the product after the reaction in step 1 into a powder in an environment of -35°C, and add 570 parts of n-butanol and 90 parts of emulsifier OP-10 to the powder to make a white suspension The product is pour point depressant and drag reducer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com