Storage mechanism of soft bag nozzle pressing machine

A bag and soft packaging technology, applied in the field of the storage mechanism of the soft bag nozzle press machine, can solve the problems of low production efficiency, high labor cost, slow production efficiency, etc., and achieve the effects of low labor cost, high degree of automation, and simple storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The scheme of this application is further described in conjunction with the accompanying drawings as follows:

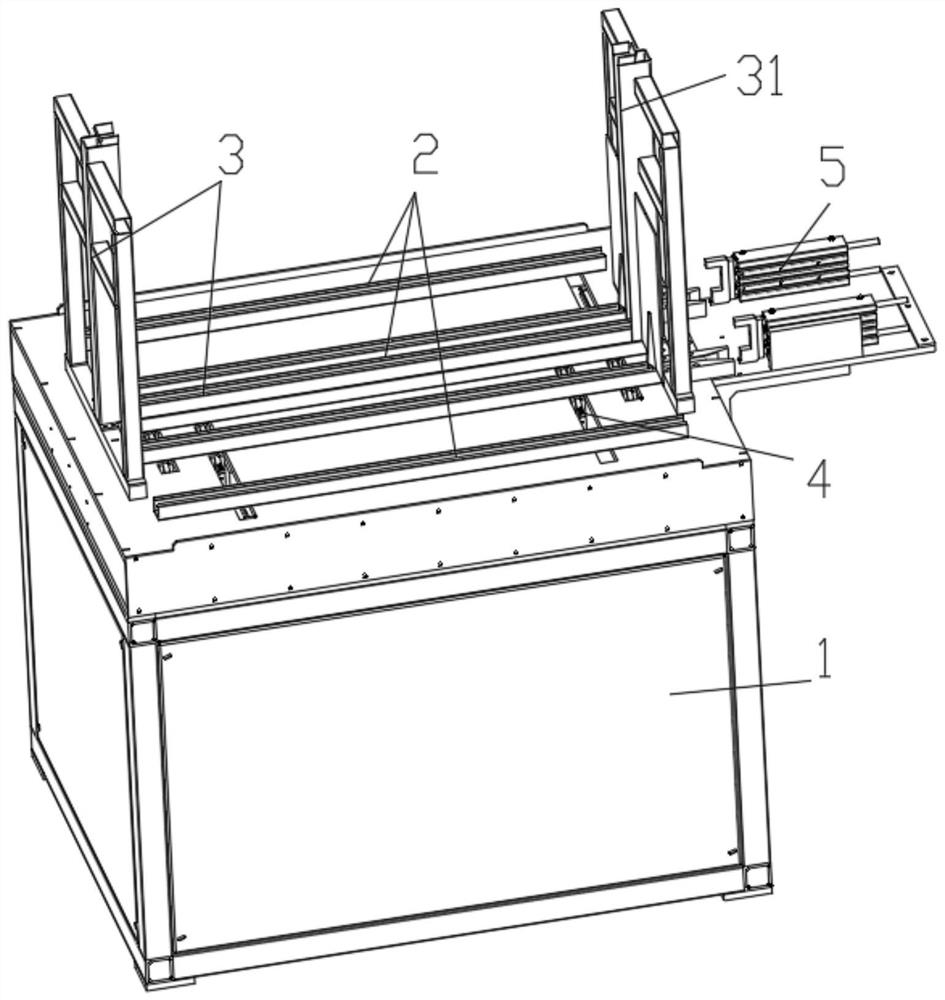

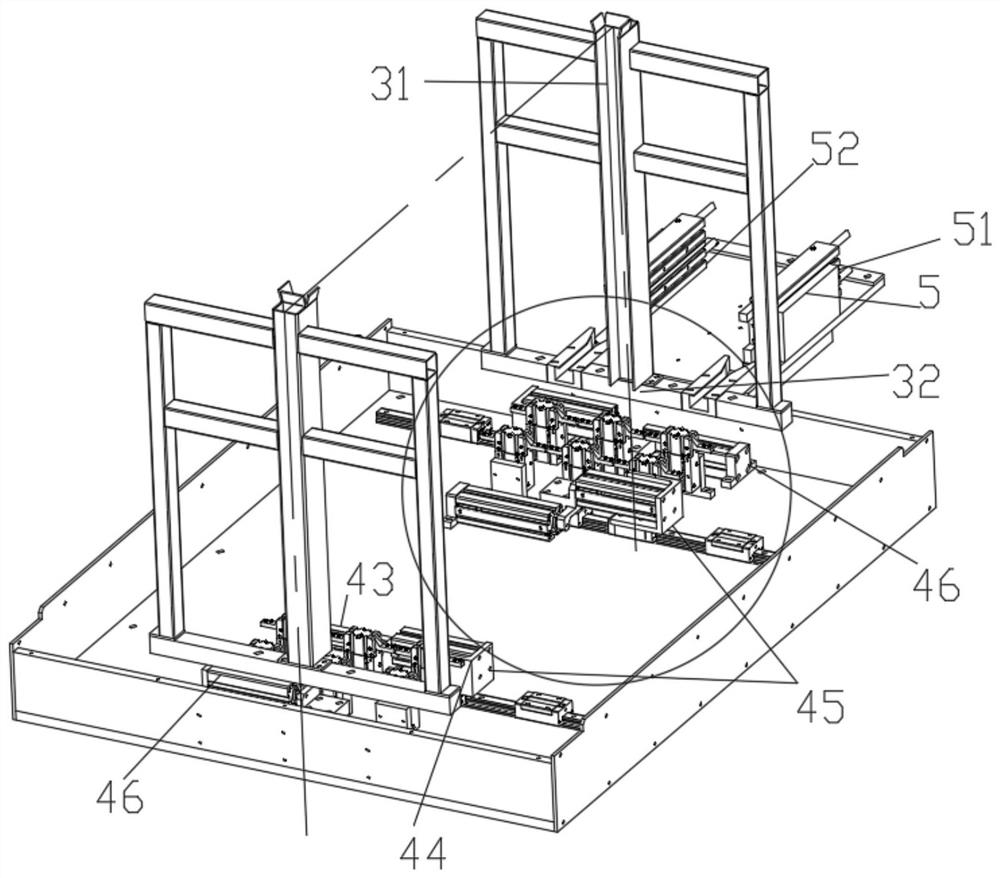

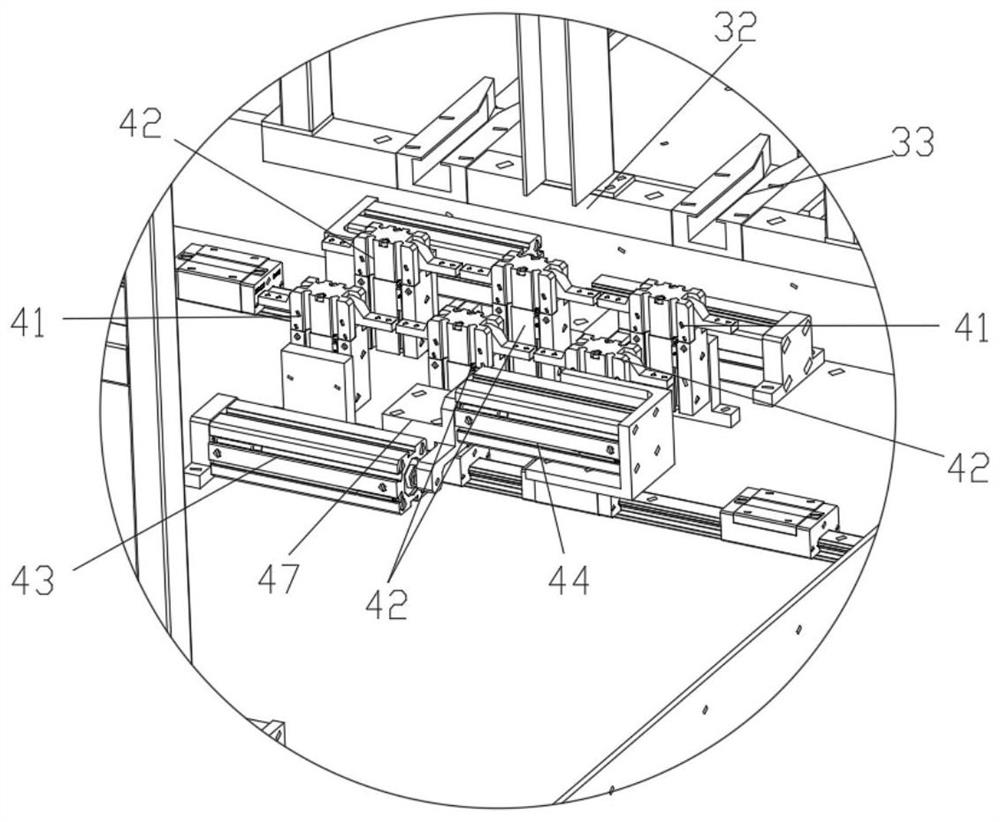

[0019] See attached Figure 1-4 A storage mechanism for a soft bag mouth press machine, including a frame 1 and a storage tank 2 installed on the frame 1, a storage tank installation area 3, a storage tank conveying mechanism 4, and a pushing mechanism 5, and the storage tanks 2 are stacked In the storage tank installation area 3, the storage tank installation area 3 is provided with two installation slots 31 oppositely arranged, and the upper end opening of the installation slot 31 and the bottom side or both sides are provided with a storage tank passing port 32, and the storage tank conveying mechanism 4 is arranged under the storage tank installation area 3 and sends the storage tank 2 from the storage tank installation area 3 to the storage area.

[0020] Preferably, the storage groove installation area 3 is a space opposite to the installation groove 31...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap