Piezoresistive effect concrete with high sensitivity and preparation method thereof

A high-sensitivity, concrete technology, applied in the field of civil engineering, can solve the problems of high price and high concrete production cost, and achieve the effects of high sensitivity, maintaining stability and repeatability, and convenient forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0049] 1.1 Material and performance requirements:

[0050] Cement: P·II 42.5 grade Portland cement, the quality meets the requirements of the GB175-2007 specification of "General Portland Cement".

[0051] The performance index of silica fume is as follows: total alkalinity 2 Content>85%, activity index>105%, specific surface area is 15m 2 / g, water absorption <125%, moisture content <3.0%.

[0052] The performance indicators of graphene nanosheets (NGPs) are as follows: purity >99.5%, diameter 5-10µm, thickness 0.4-20nm, number of layers 1-5, density 0.23g / cm 3 , volume resistivity 4×10 -4 Ω·cm.

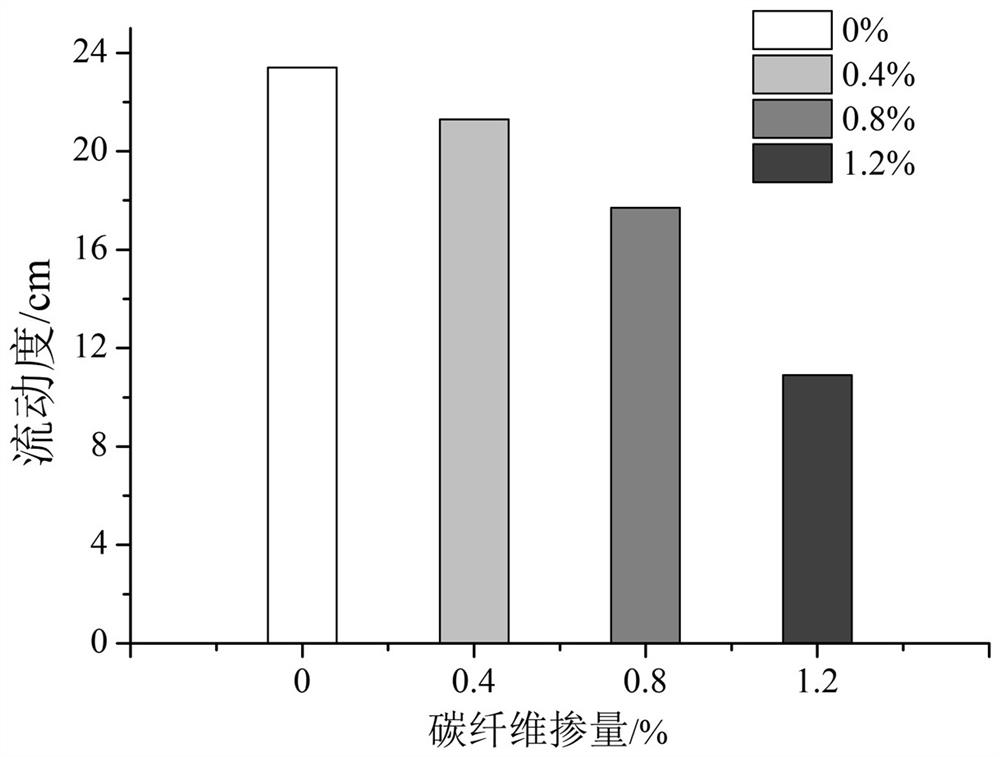

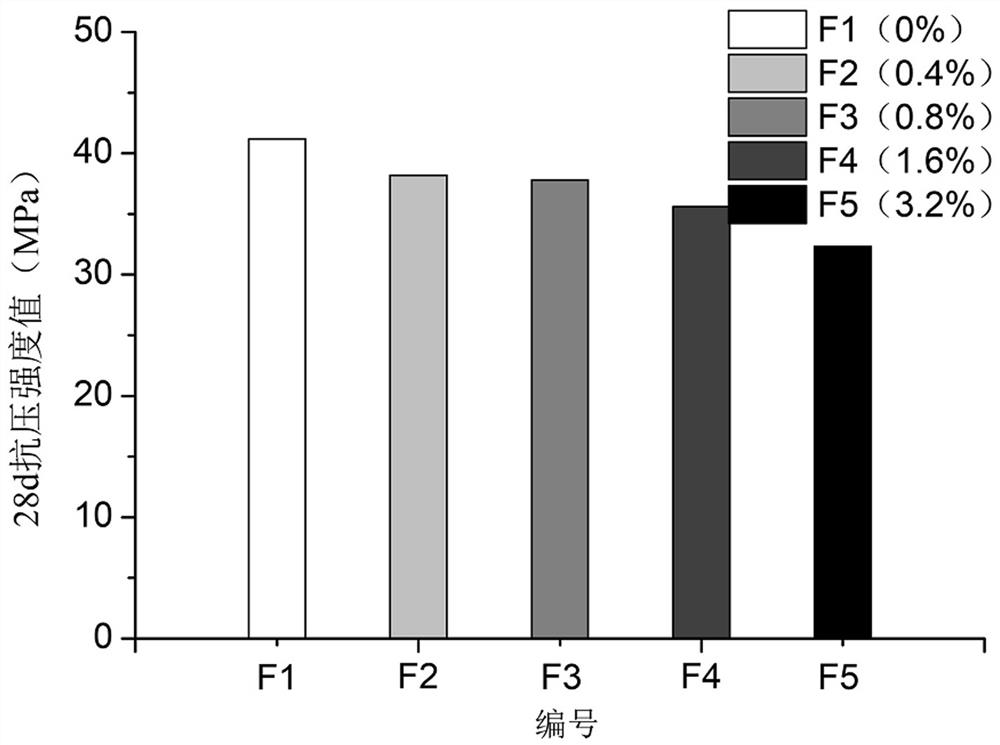

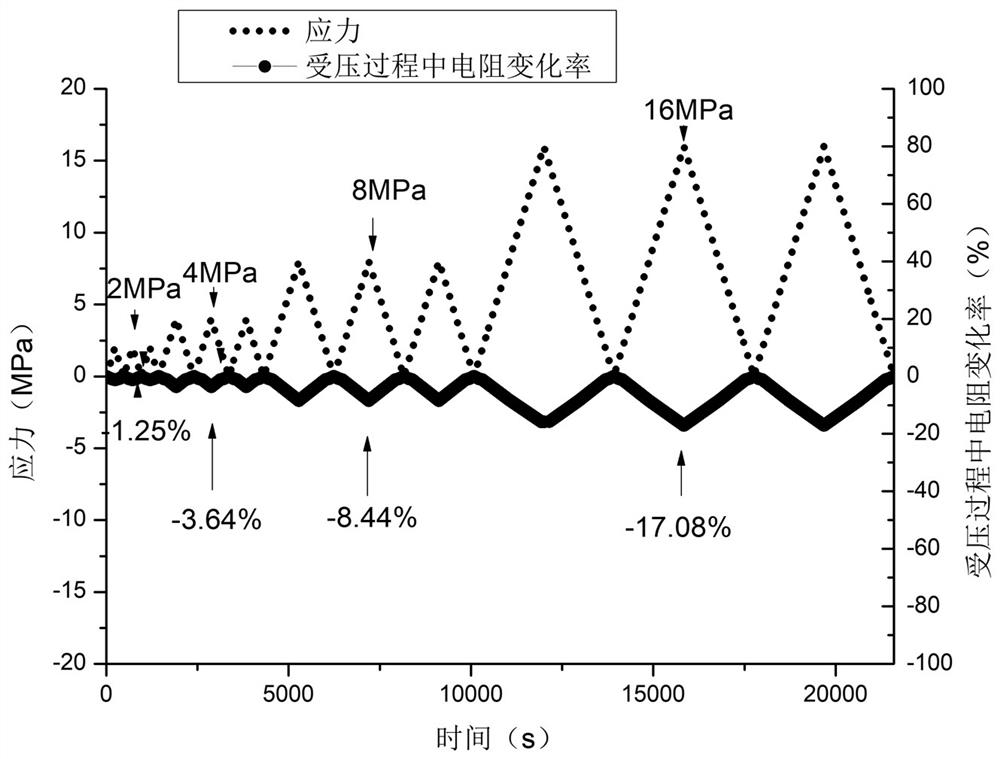

[0053] Carbon fiber (CF) performance indicators are as follows: diamete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com