N-butane isomerization system

A technology of isomerization and n-butane, which is used in the fields of isomerization to produce hydrocarbons, organic chemistry, hydrocarbons, etc., can solve the problem of isobutane waste, and achieve the effect of reducing waste and accelerating volatilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions and technical effects of the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings of the present invention.

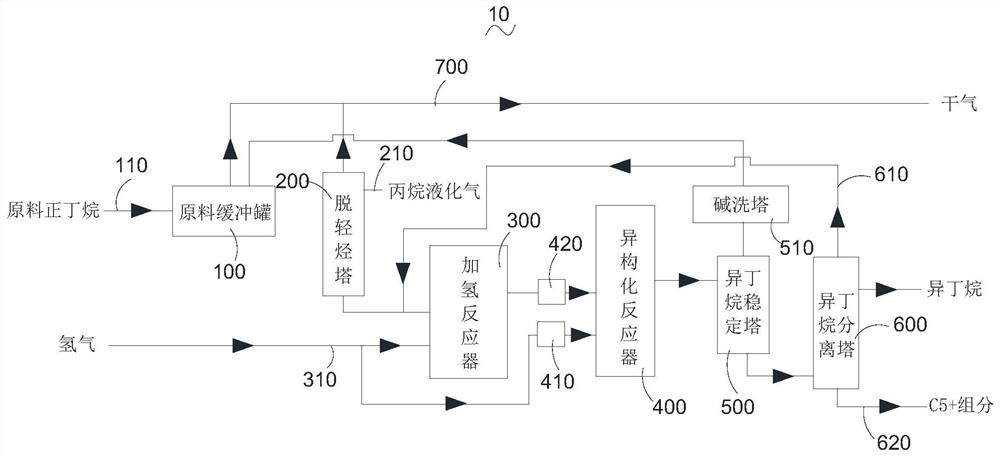

[0021] Please see figure 1 , in a specific embodiment, a n-butane isomerization system 10 includes a raw material buffer tank 100 connected by pipelines, a light hydrocarbon removal tower 200, a hydrogenation reactor 300, an isomerization reactor 400, an isobutane Stabilize the tower 500 and the isobutane separation tower 600 .

[0022] The raw material buffer tank 100 is used to initially remove light components in the raw material n-butane, the raw material buffer tank 100 is connected with a normal butane feed pipe 110, and the gas phase of the raw material buffer tank 100 is connected with a dry Gas collection tube 700. The raw material n-butane first enters the raw material buffer tank 100, under the slight negative pressure, light components of C3 and below ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com