Electric control system of full-automatic double-head quilting machine

An electric control system and fully automatic technology, applied in the direction of sewing machine control devices, sewing machine components, sewing machines for bedding, etc., can solve the problems of cumbersome, speed limit, broken needles, etc., achieve high-efficiency quilting, reduce manpower, Ease of production management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

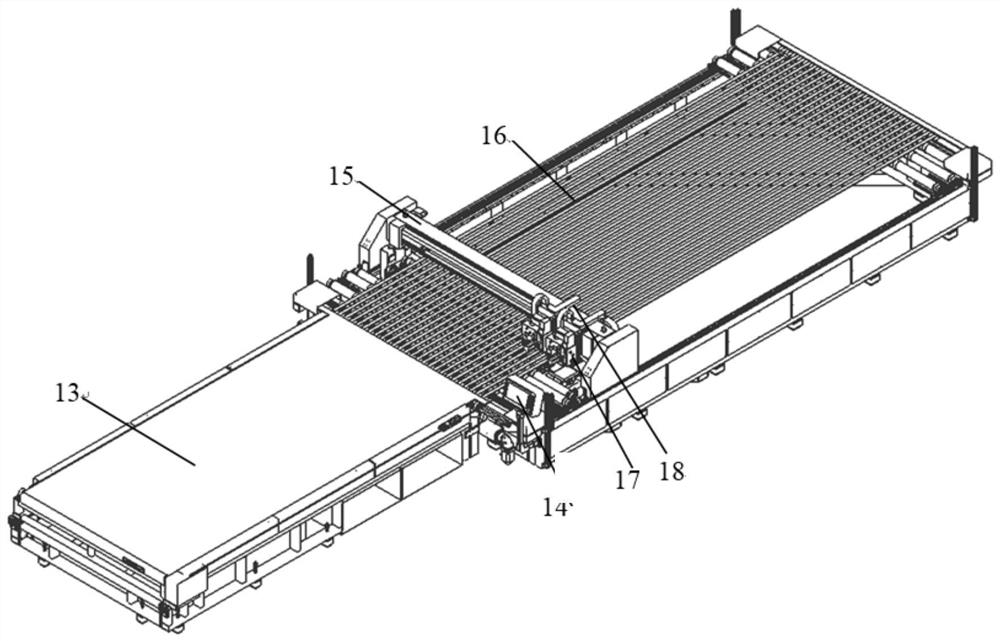

[0030] In order to further understand the content, features and effects of the present invention, the following examples are given and described in detail with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

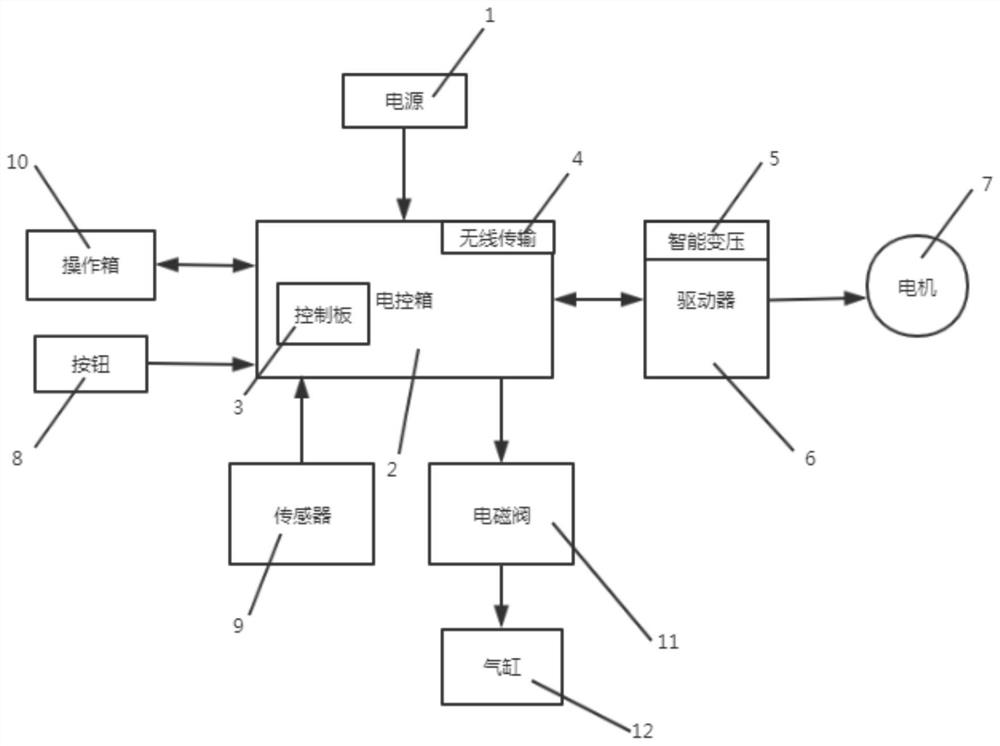

[0031] The electric control system of the automatic double-head quilting machine realizes the electric control process of the whole machine by the mutual operation among the power supply circuit, the control circuit board, the operation box, the motor part, the solenoid valve, the sensor and the button.

[0032] The control circuit board (3), wireless data transmission module (4), contactor and filter power supply control components are located in the electric control box (2).

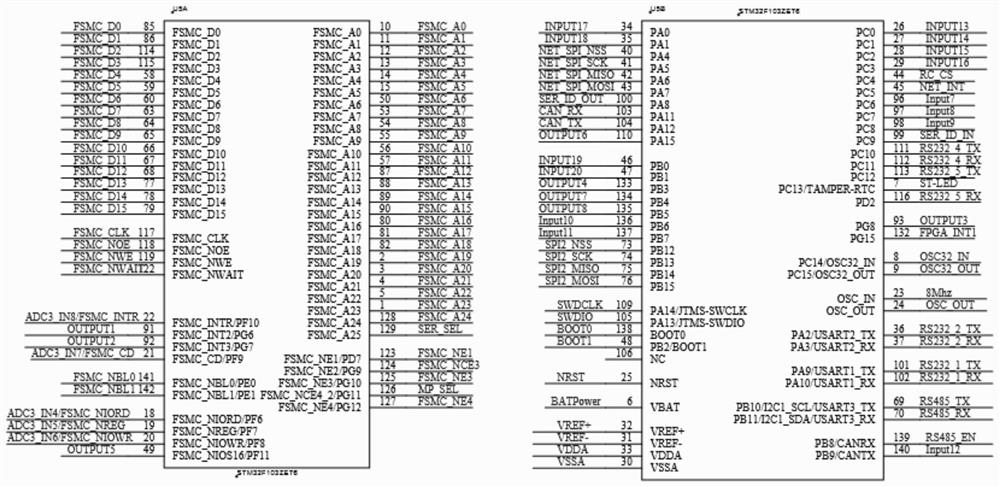

[0033] The control circuit board (3) mainly completes data input and output, processing, analysis, coordination control, and directly processes and controls act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com