Electromotor drive train for a vehicle axle

A drive system and axle technology, applied in the direction of electric power units, power units, vehicle components, etc., can solve the problems of large size, and achieve the effects of simplified integration and adaptation, assembly cost and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

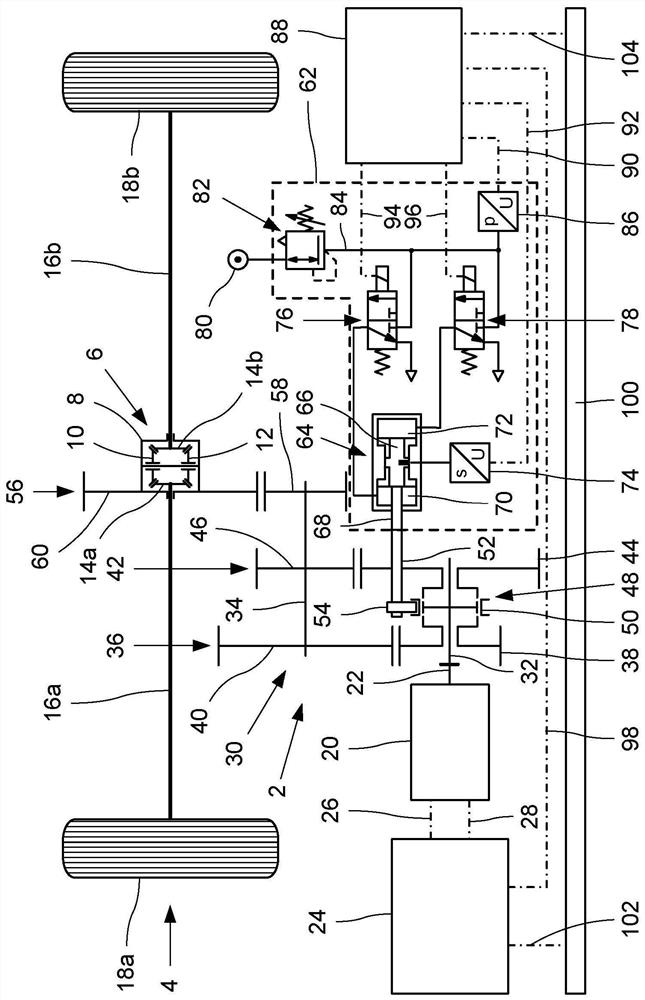

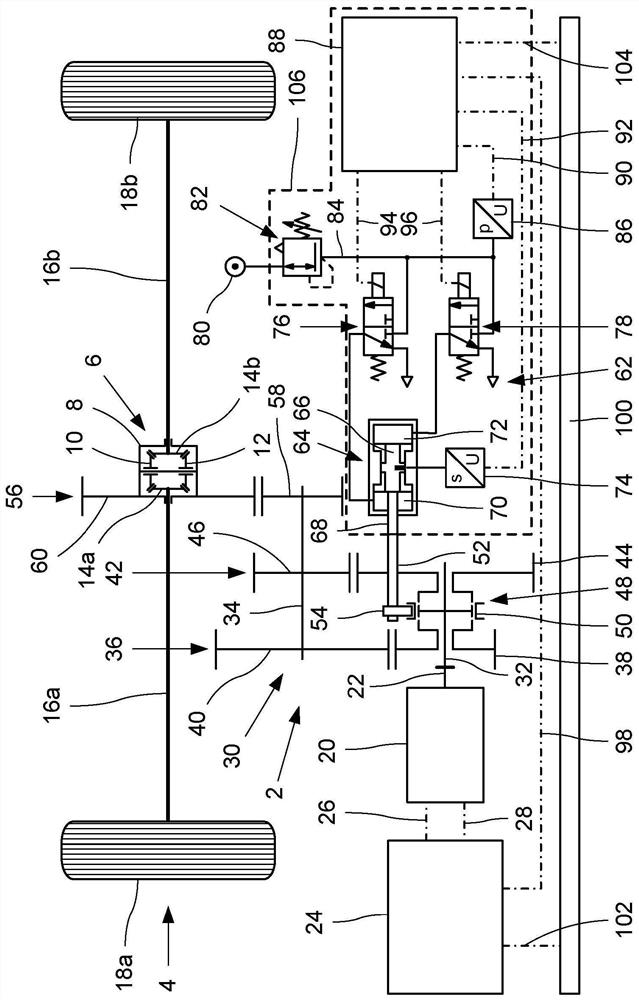

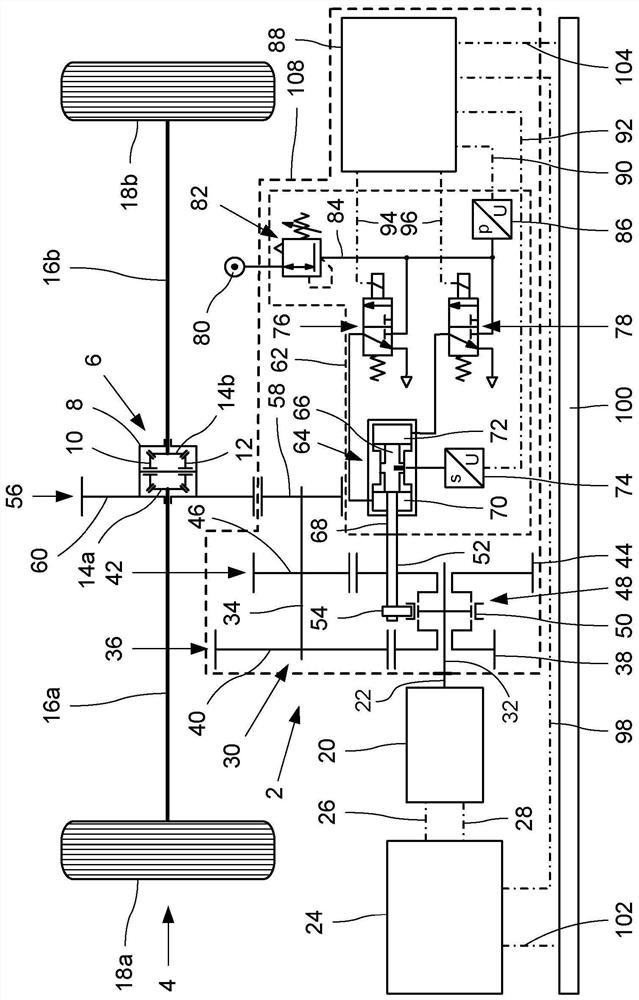

[0021] exist figure 1 The electric drive train 2 of the axle 4 shown schematically in FIG. The switching device 62 for the switching operation of the transmission 30. The shift transmission 30 is arranged between the drive shaft 22 of the electric machine 20 and the axle differential 6 of the axle 4 and has two transmission ratio stages 36 , 42 that can be shifted by means of a shifting sleeve 50 .

[0022] An electronic motor control unit 24 is assigned to the electric motor 20 , which is connected to the electric motor 20 via at least one electrical sensor line 26 and an electrical control line 28 . For example, values of the motor speed and / or the motor load of the electric machine 20 can be transmitted via the sensor line 26 to the motor control unit 24 . Via the control line 28 , the electric motor 20 is correspondingly controlled by the motor control unit 24 in order to set a specific motor rotational speed and / or a specific motor torque.

[0023] The shift transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com