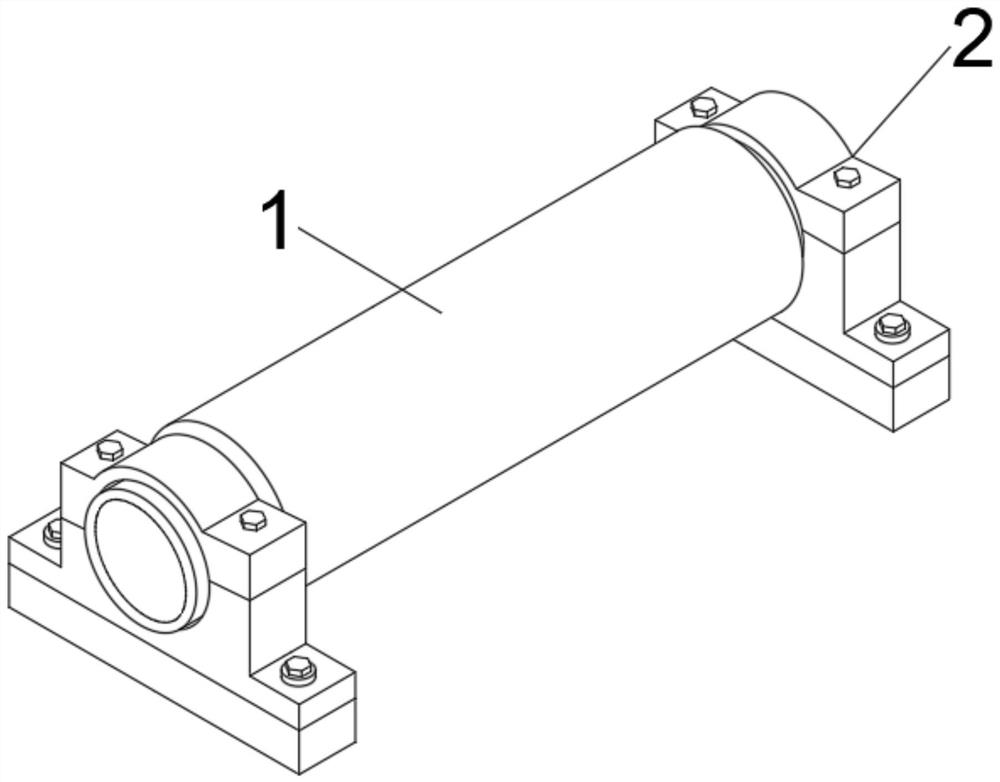

Pipeline metal shock absorber

A shock absorber and pipeline technology, applied in the direction of pipe elements, pipe supports, pipes/pipe joints/pipe fittings, etc., can solve the problem of no metal shock absorbers, etc., and achieve strong design, compact space structure, and environmental adaptability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

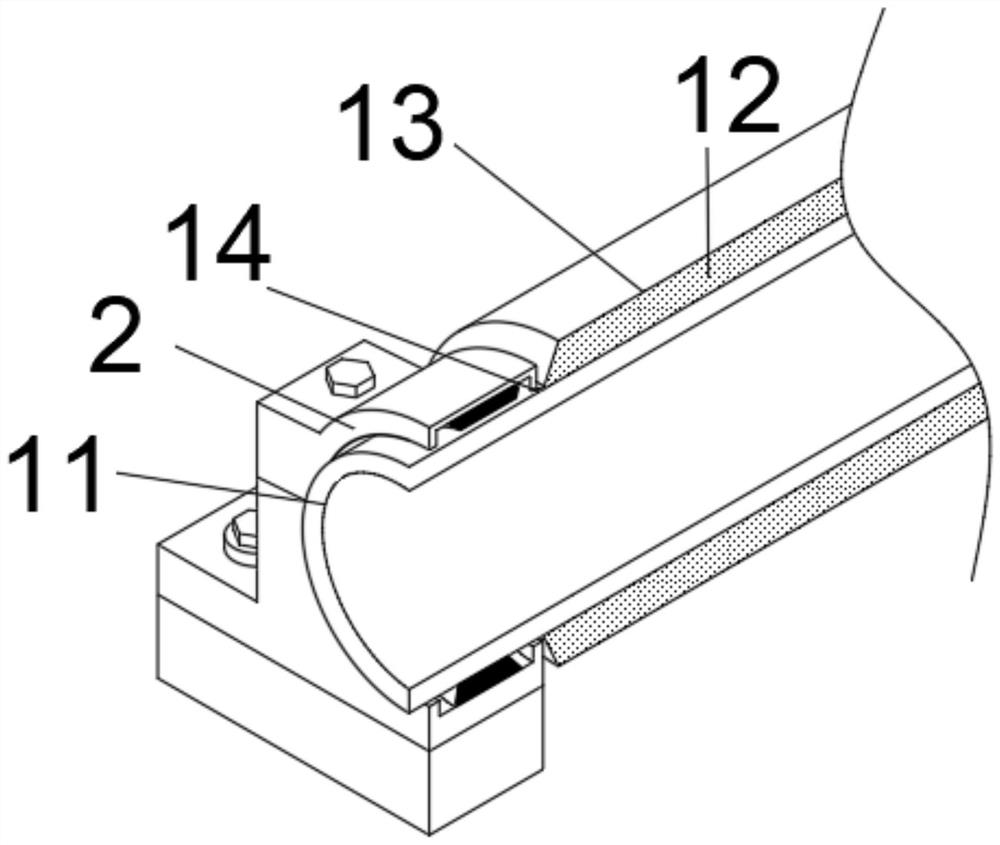

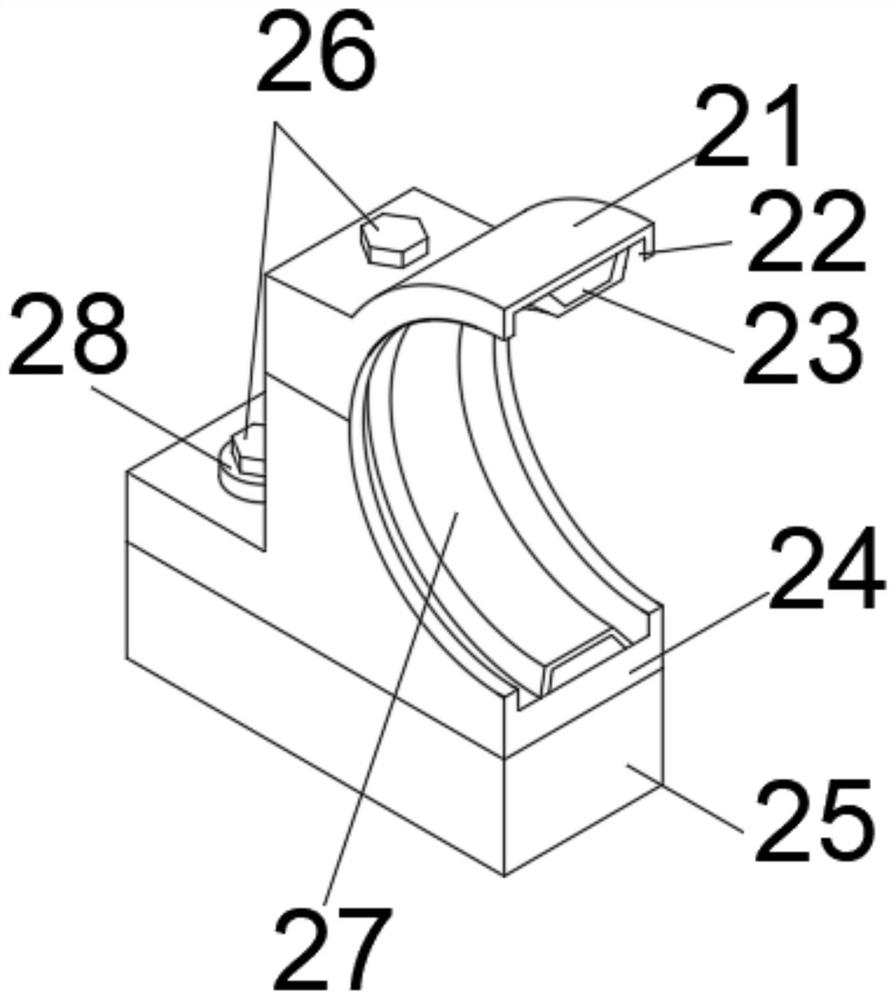

[0032] By increasing the damping method at the installation place of the pipeline, the vibration of the pipeline system is reduced. In particular, there are few studies on the design of rocket booster pipeline vibration reduction. As an important part of the rocket booster delivery system, the pipeline is a single-point failure component, which will directly affect the success or failure of the flight. In the history of launch vehicle and weapon development, there have been many flight failures and even failures caused by broken pipelines. The pipeline system vibration reduction method designed in this paper is to realize the overall vibration reduction of the pipeline system, including particle damping technology, metal vibration reduction technology, elastic support design of joints and other key design points.

[0033] The characteristic of this particle damping and vibration reduction structure design scheme is that the particle damping technology is applied. The vibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com