Ultrathin carbon nitride nanosheet rich in nitrogen defects, preparation method of ultrathin carbon nitride nanosheet and method for preparing hydrogen peroxide through photocatalysis

A technology of hydrogen peroxide and carbon nitride, which is applied in chemical instruments and methods, physical/chemical process catalysts, nanotechnology, etc., can solve the problems of low photocatalytic efficiency of carbon nitride, and achieve strong environmental tolerance and easy Good operation and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080] The invention provides a method for preparing ultrathin nitrogen-deficient carbon nitride nanosheets, comprising the following steps:

[0081] 1) After melamine is calcined for the first time, bulk phase carbon nitride is obtained;

[0082] 2) after the bulk phase carbon nitride obtained by the above steps is subjected to thermal stripping through second calcination, obtain carbon nitride ultrathin nanosheets;

[0083] 3) In a nitrogen atmosphere, the carbon nitride ultrathin nanosheets obtained in the above steps are calcined for the third time to obtain nitrogen-deficient carbon nitride nanosheets.

[0084] In the present invention, the melamine is calcined for the first time to obtain bulk carbon nitride.

[0085] In the present invention, the heating rate of the first calcination is preferably 2-10°C / min, more preferably 3-9°C / min, more preferably 4-8°C / min, more preferably 5-7°C / min.

[0086] In the present invention, the temperature of the first calcination is...

Embodiment 1

[0123] (1) Preparation of bulk carbon nitride

[0124] Weigh 5g of melamine, put it into a 30mL crucible after grinding, cover it, and place it in a muffle furnace. Raise the temperature to 550°C at a rate of 2.5°C / min, keep it for 4 hours, then naturally cool to room temperature, and grind thoroughly to obtain light yellow bulk carbon nitride powder.

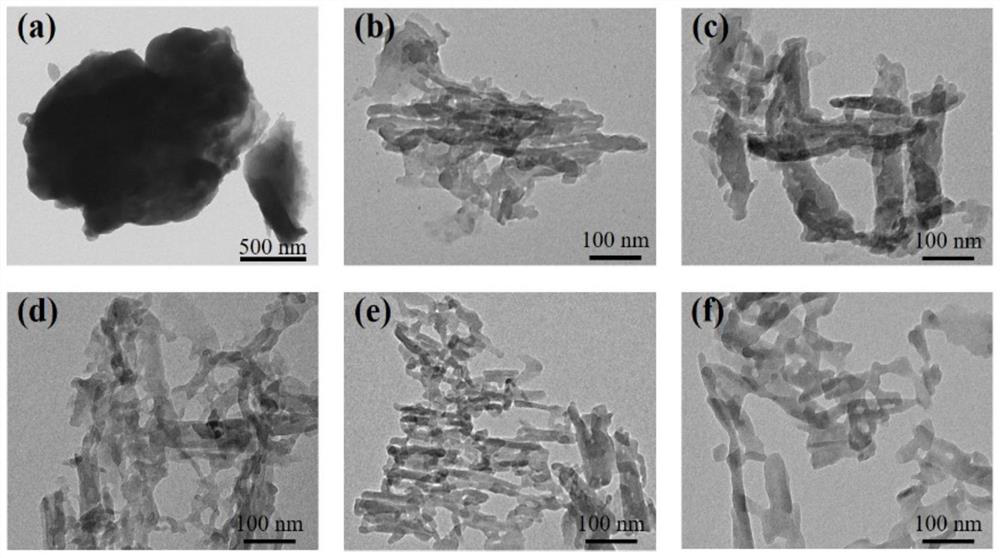

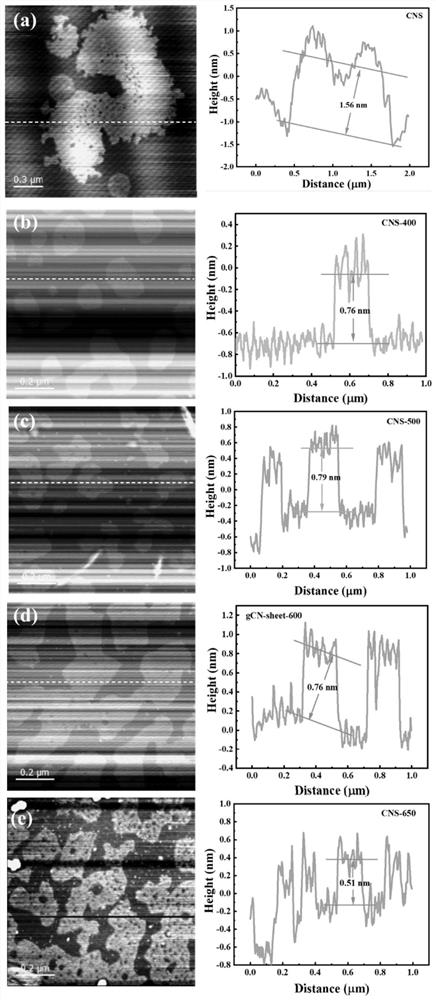

[0125] (2) Preparation of carbon nitride nanosheets

[0126] Spread the bulk carbon nitride powder evenly on the bottom of the open crucible, place it in a muffle furnace, raise the temperature to 520 °C at a rate of 2.5 °C / min, keep it for 4 hours, and then cool it naturally to room temperature to obtain white nitrogen carbonized ultrathin nanosheets.

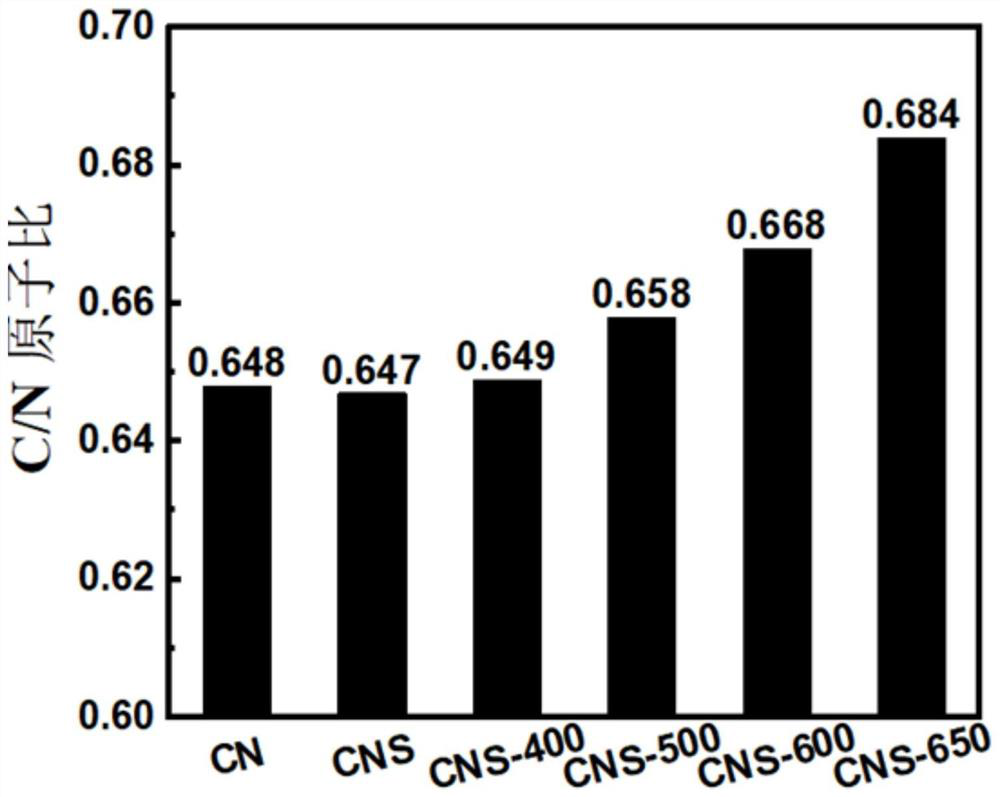

[0127] (3) Preparation of nitrogen-deficient carbon nitride nanosheets

[0128] Place the white carbon nitride ultra-thin nanosheets in an open porcelain boat and put them into a tube furnace. During the whole process, nitrogen gas is introduced at a rate of 100 mL / min, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Light wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com