Large-air-volume replacement type fresh air system based on total heat recovery of air source heat pump

An air source heat pump, total heat recovery technology, applied in heat recovery systems, ventilation and heating energy recovery systems, air conditioning systems, etc., can solve the problems of limited classroom space, substandard air quality, no major breakthroughs, etc. The effects of good economic and environmental benefits, low construction and operation costs, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

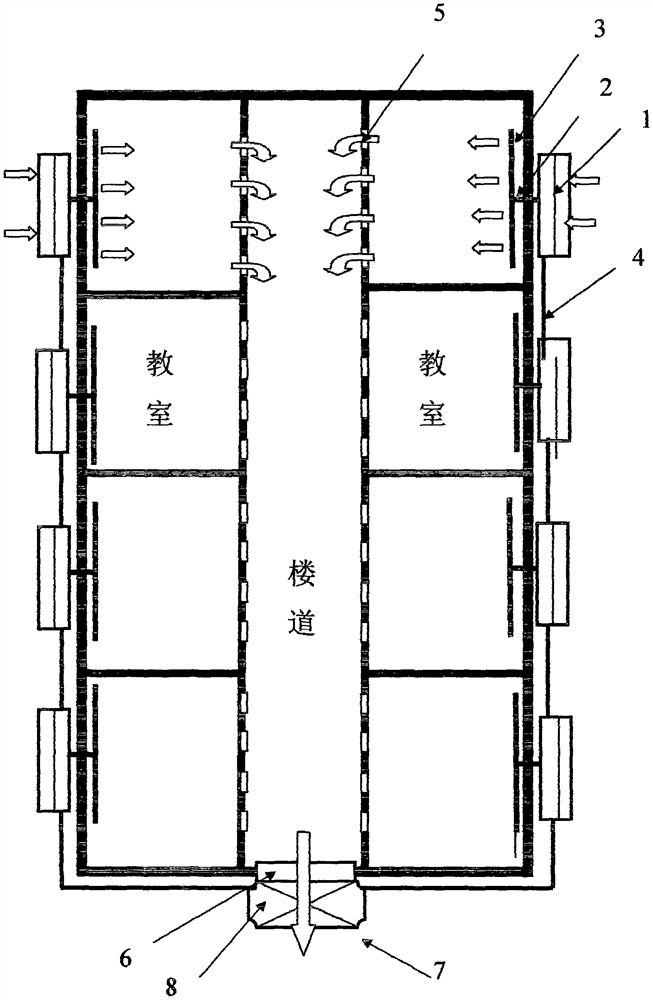

[0059] This embodiment is an embodiment in which 8 classrooms are equipped with a dedicated air source heat pump. The fresh air purification heating unit, the exhaust air heat recovery unit and the working fluid circulation pipeline are all installed outdoors.

[0060] like figure 1 -- image 3 As shown, the technical solution of the present invention is to design a large air volume replacement fresh air system based on the total heat recovery of the air source heat pump, including: fresh air purification heating unit 1, air supply pipe 2, air supply port 3, and liquid working medium circulation pipe 4 , 5 outlet shutters, 6 exhaust ducts, 7 exhaust heat recovery units, and 8 dedicated air source heat pumps.

[0061] Outdoor fresh air (fresh air) enters the fresh air purification heating unit 1, first enters the air volume distribution channel of the fresh air purification part, and then passes through the coarse filter layer, pretreatment filter layer, gas purification laye...

Embodiment 2

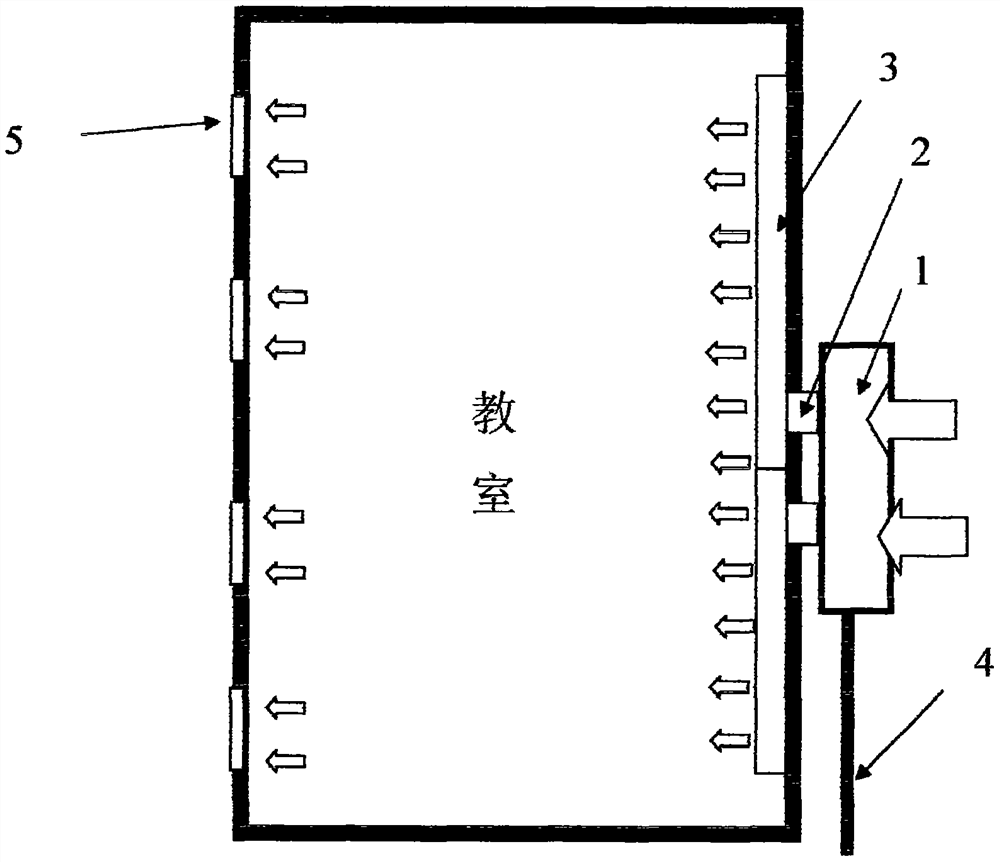

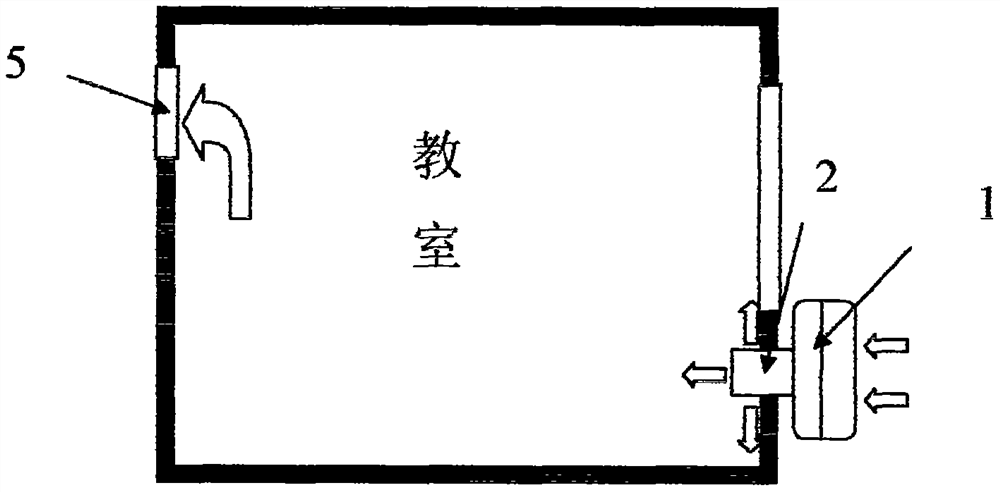

[0075] This embodiment is an embodiment in which 8 classrooms are equipped with a dedicated air source heat pump. The fresh air purification heating unit, the exhaust air heat recovery unit and the working fluid circulation pipeline are all installed indoors.

[0076] like Figure 4-Figure 6 As shown, the technical solution of the present invention is to design a large-volume replacement fresh air system based on the total heat recovery of an air source heat pump, including a fresh air purification heating unit 1, an air supply port 3, a liquid working medium circulation pipeline 4, an outlet louver 5, and a ventilation system. Air duct 6, exhaust air heat recovery unit 7, dedicated air source heat pump 8.

[0077] The chassis of the fresh air purification heating unit 1 is placed on the ground at a position where the windows are not blocked before and after the classroom. The air inlet 2 is installed on the outer wall or the opening of the window, and is connected with the c...

Embodiment 3

[0091] This embodiment is an embodiment in which a venue with 500 seats is equipped with two dedicated air source heat pumps. The fresh air purification heating unit and the working fluid circulation pipeline are installed indoors, and the exhaust heat recovery unit is installed outdoors.

[0092] like Figure 7-Figure 8 As shown, the technical solution of the present invention is to design a large-volume replacement fresh air system based on the total heat recovery of an air source heat pump, including a fresh air purification heating unit 1, an air inlet pipe 2, an air outlet pipe 3, an air outlet 4, and a working medium Circulation pipeline 5, exhaust duct 6, special air source heat pump 8

[0093] The chassis of the fresh air purification heating unit 1 is placed on the floor or hung on the backstage room, and the air inlet duct 2 is installed on an opening through an outer wall or a window, and is connected with the interface of the fresh air purification heating unit 1 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com