Robot Management System And Control Method For Robot Management System

A technology of management system and control method, applied in the field of robot management system and robot management system control, can solve problems such as program difference and program recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0028] First, a first embodiment will be described.

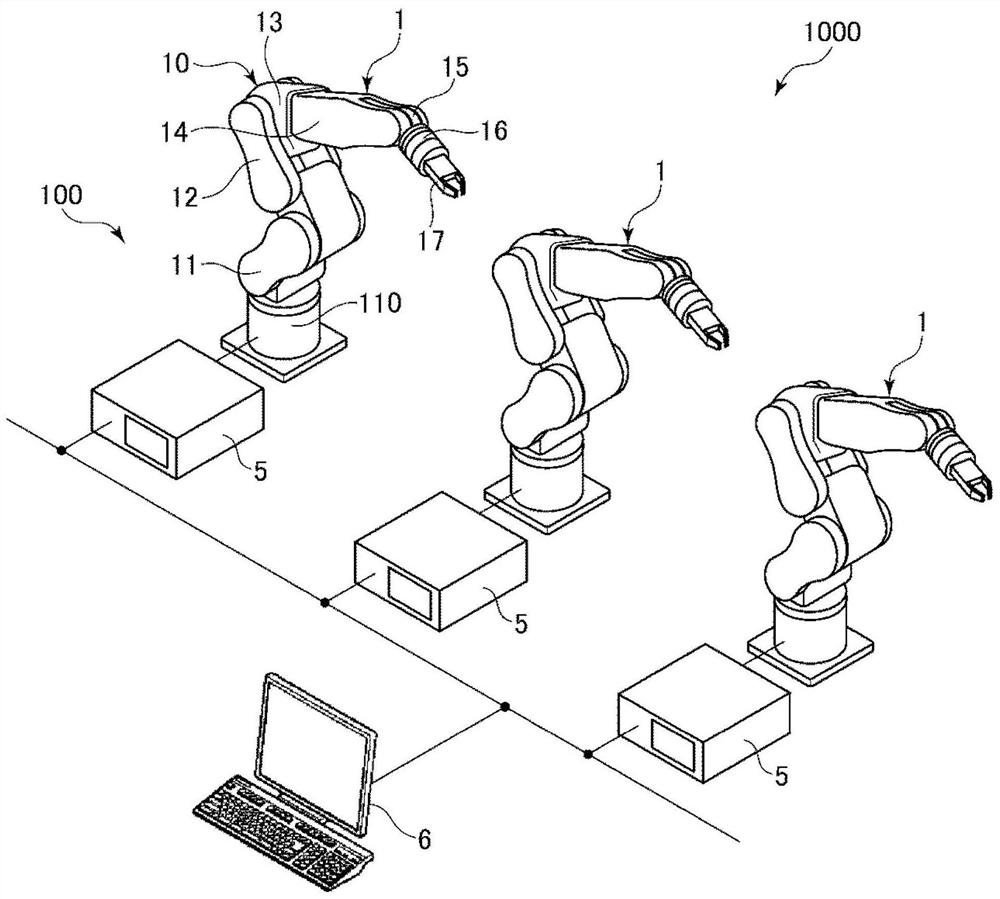

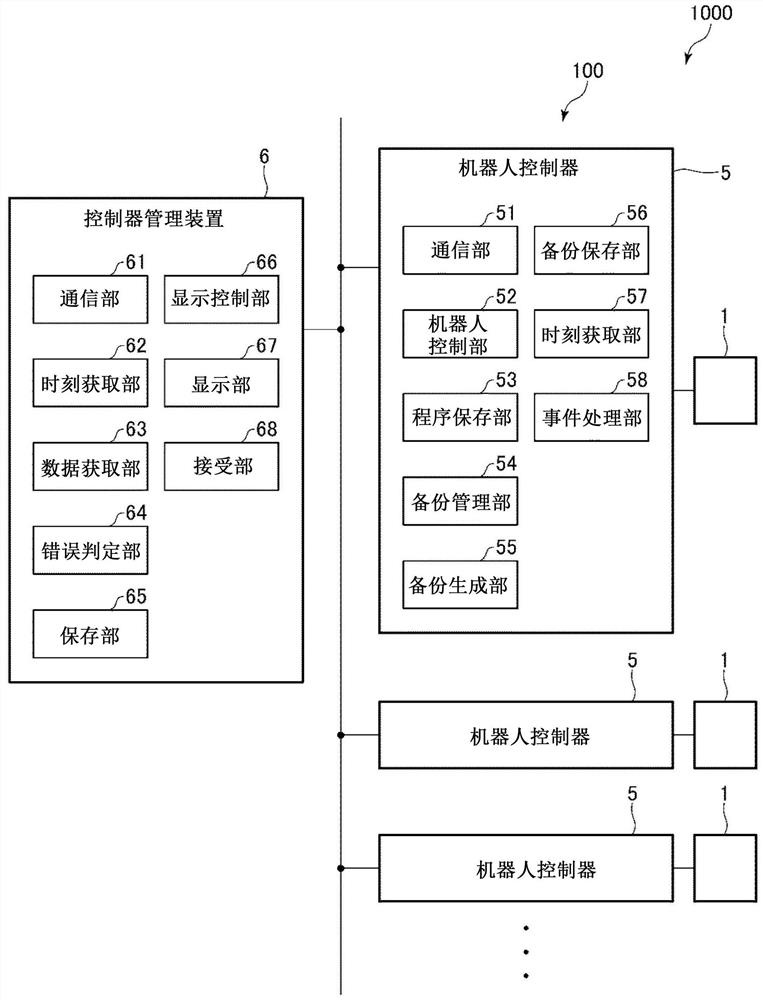

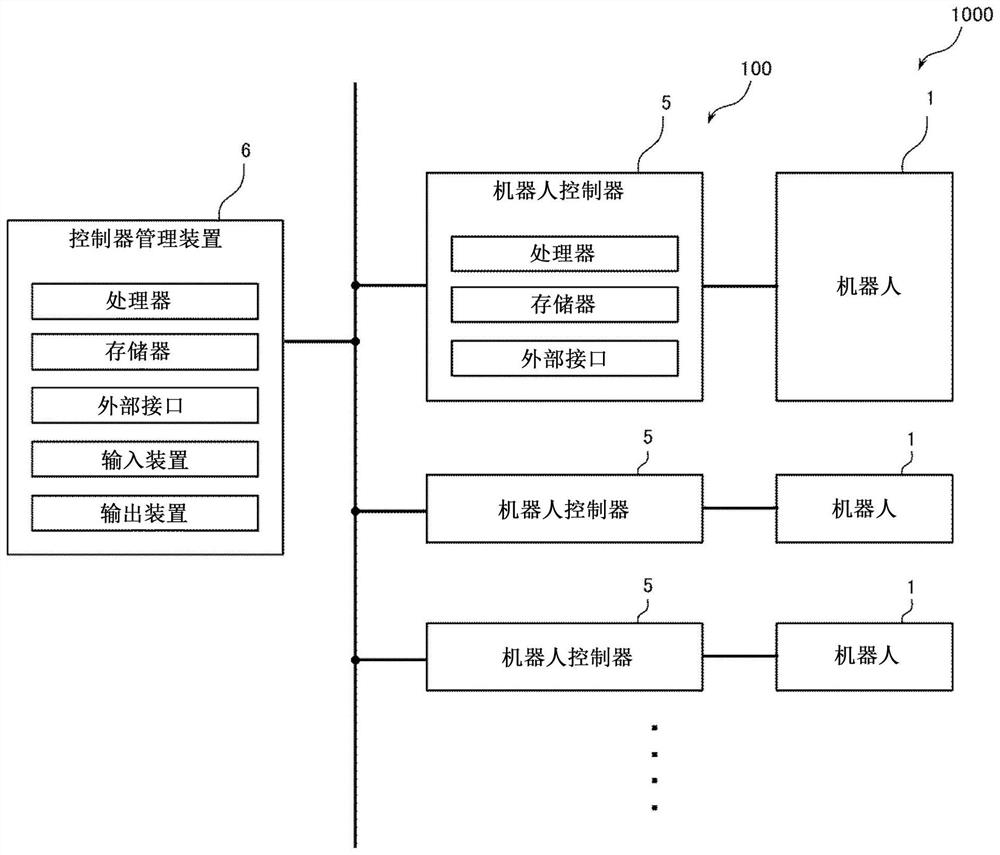

[0029] figure 1 It is a perspective view showing the robot management system of the first embodiment. figure 2 yes figure 1 Functional block diagram of the robot management system shown. image 3 is to show the implementation figure 2 A conceptual diagram of an example of the hardware configuration of the functions of the robot management system shown.

[0030] In addition, in this specification, "connection" means both the case of direct connection and the case of indirect connection via arbitrary components.

[0031] 1.1 Robot management system

[0032] figure 1 The shown robot management system 100 has a robot controller 5 that controls the driving of the robot 1 and a controller management device 6 that manages the robot controller 5 .

[0033] Such a robot management system 100 controls the driving of the robot 1 as a manipulator by being connected to the robot 1 . As a result, the robot 1 can perform various...

no. 2 approach

[0144] Next, a second embodiment will be described.

[0145] Figure 7 It is a functional block diagram showing the robot management system of the second embodiment. Figure 8 It is a flowchart showing the control method of the robot management system of the second embodiment.

[0146] Next, the second embodiment will be described. In the following description, differences from the first embodiment will be mainly described, and descriptions of the same items will be omitted. It should be pointed out that Figure 7 and Figure 8 In , the same symbols are attached to the same configuration as that of the first embodiment.

[0147] In the above-mentioned first embodiment, the user is reminded to update the backup data 8 by displaying the notification content on the display unit 67, but in this embodiment, the backup data 8 is performed based on an instruction from the controller management device 6. update job.

[0148] in particular, Figure 7 The illustrated controller m...

no. 3 approach

[0161] Next, a third embodiment will be described.

[0162] Figure 9 It is a functional block diagram showing the robot management system of the third embodiment. Figure 10 It is a conceptual diagram showing an example of the contents of the notification 7 acquired by the controller management device 6 .

[0163] Next, the third embodiment will be described, and in the following description, the differences from the second embodiment will be mainly described, and the description of the same items will be omitted. It should be pointed out that Figure 9 In , the same reference numerals are assigned to the same configurations as those of the second embodiment.

[0164] In the above-mentioned second embodiment, the controller management device 6 is provided with the error determination unit 64, but in the present embodiment, as Figure 9 As shown, the robot controller 5 includes an error determination unit 59 . Therefore, in the first embodiment, the error determination un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com