Artificial turf yarn with improved processibility and friction management

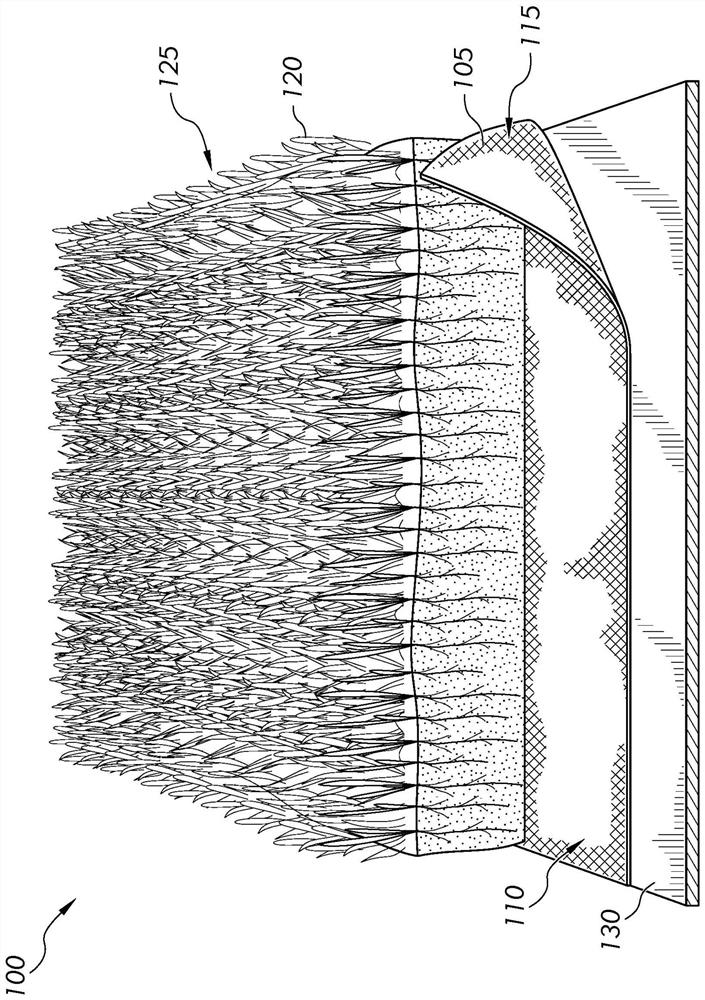

An artificial turf, filament technology, applied in rayon manufacturing, textile and papermaking, one-component polyolefin rayon, etc., can solve problems such as increased incidence of skin abrasions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] Preparation method of artificial turf filament

[0053] Similarly, other embodiments relate to methods of making artificial turf. The artificial turf filaments described herein may be prepared using any suitable method for producing artificial turf filaments from the formulations described above.

[0054] The present artificial turf filaments may be prepared by extrusion, specifically by mixing the base vinyl polymer and one or more PDMS components. A suitable artificial turf filament extruder can be equipped with a single common screw and a melt pump ("gear pump" or "melt pump") to precisely control the consistency of the polymer volume flow into the die. Artificial turf filament dies may have multiple single holes for individual filaments distributed over annular or rectangular spinnerets. The shape of the hole corresponds to the desired cross-sectional shape of the filament, including, for example, rectangular, dog-bone, v-shaped, and Mexican hat. A standard spi...

example

[0082]The following examples illustrate one or more features of the disclosure. The examples of the present invention demonstrate improved friction control using artificial turf filaments of the present formulation. The polymer components used in the examples are provided below.

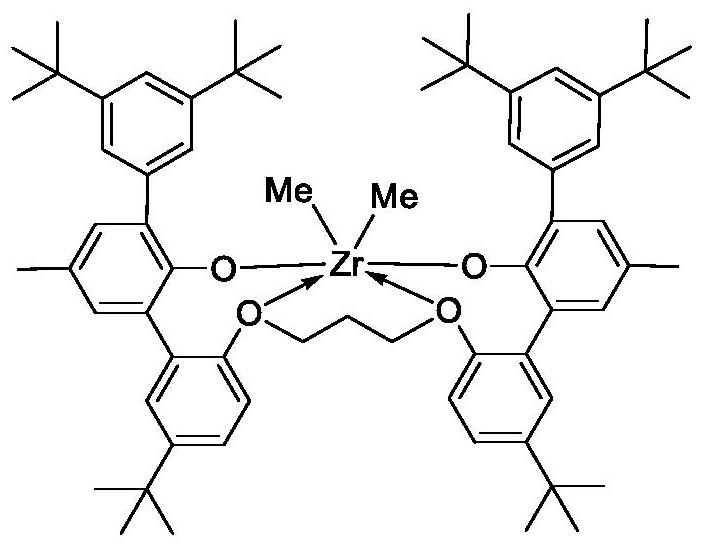

[0083] The UHMW PDMS component is MB50-613, which is a DOWLEX TM 2035G UHMW PDMS masterbatch in LLDPE carrier, it contains the polysiloxane of 50 weight % and M n = 300,000 g / mol. DOWLEX TM The density of 2035G = 0.919g / cc, and the melt index I 2 = 6.0 g / 10 min. MB50-613 masterbatch was produced by The Dow Chemical Company, Midland, MI.

[0084] The HMW PDMS component is MB25-502, which is a dispersed in I 2 HMWPDMS master batch in LDPE carrier of 8g / 10min, its siloxane content is 25% by weight and M n = 17,000 g / mol. MB25-502 masterbatch is manufactured by The Dow Chemical Company, Midland, MI.

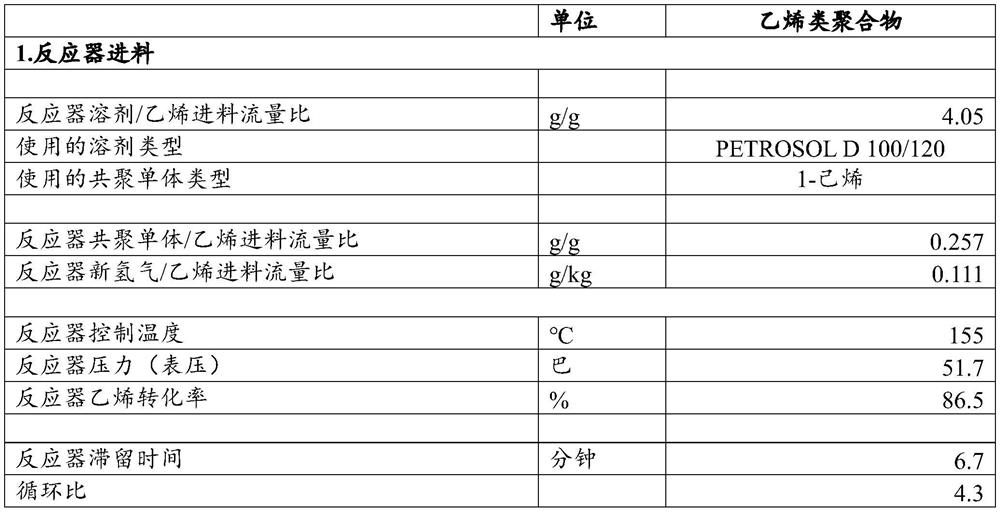

[0085] The basic vinylic polymer is an ethylene-hexene copolymer prepared by a solution polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com