Adhesive self-repairing hemostatic membrane and preparation method thereof

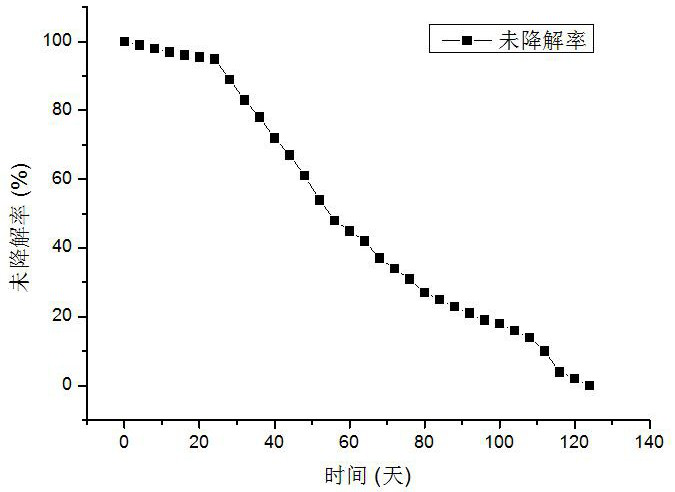

A self-healing, hemostatic film technology, used in pharmaceutical formulations, bandages, drug delivery, etc., can solve the problems of high swelling rate, poor wound adhesion performance, poor adhesion performance, etc., achieve high mechanical strength, and accelerate hemostasis efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

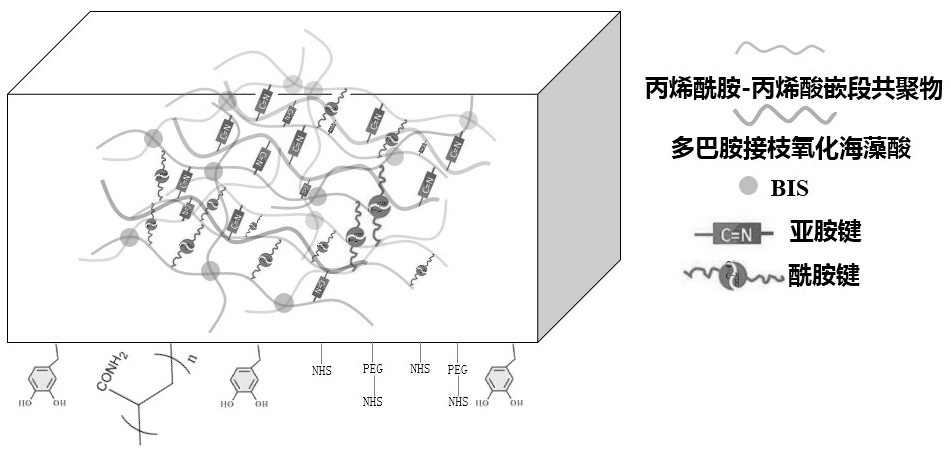

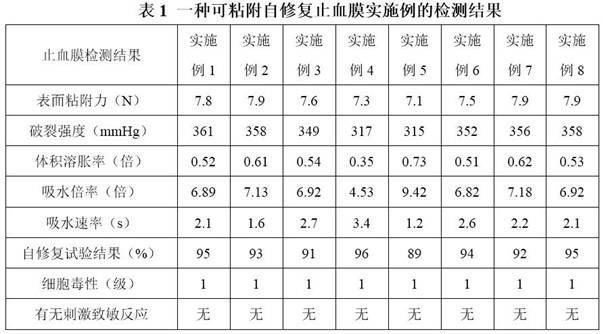

[0051] Example 1: Graft oxidized alginic acid with a mass fraction of 2.5% of dopamine (the degree of oxidation is 85%, the grafting rate of dopamine is 15%, and the viscosity is 300 mPa·s), 30% acrylamide, and 5% acrylic acid N-hydroxyl Add succinimide ester and 0.015% N,N'-methylenebisacrylamide into purified water, stir at 100-200rpm until completely dissolved, continue stirring for 20min, add 1.6% 2-hydroxy-2-methyl -1-[4-(2-Hydroxyethoxy)phenyl]-1-propanone, 20% acrylic acid and 0.6% calcium chloride, stir at 100-200rpm until the solution is uniform, at a power of 150W, a wavelength of 365nm , pre-polymerized under ultraviolet light for 30 minutes, took out the prepolymer, sprayed 1.0% acrylate PEG-N hydroxysuccinimide ester, 0.6% dopamine, 0.4% acrylamide, 3% acrylic acid N-hydroxysuccinimide on the surface A mixture of urethane and 0.018% 2-hydroxy-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-propanone, under a UV lamp with a power of 150W and a wavelength of 365nm Polymer...

Embodiment 2

[0052] Example 2 Graft oxidized alginic acid with a mass fraction of 3.5% dopamine (oxidation degree is 80%, dopamine grafting rate is 10%, viscosity is 200mPa·s), 25% acrylamide, 3% acrylic acid N-hydroxyl Add succinimide ester and 0.020% N,N'-methylenebisacrylamide into purified water, stir at 100-200rpm until completely dissolved, continue stirring for 20min, add 1.6% 2-hydroxy-2-methyl -1-[4-(2-hydroxyethoxy)phenyl]-1-propanone, 25% acrylic acid and 0.4% calcium chloride, stir at 100-200rpm until the solution is uniform, at a power of 150W, a wavelength of 365nm , pre-polymerized under ultraviolet light for 20 minutes, took out the prepolymer, sprayed 1.5% acrylate PEG-N hydroxysuccinimide ester, 1.25% dopamine, 0.6% acrylamide, 4% acrylate N-hydroxysuccinimide on the surface A mixture of urethane and 0.028% 2-hydroxy-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-propanone, under a UV lamp with a power of 150W and a wavelength of 365nm Polymerize for 15min. The polymerized ge...

Embodiment 3

[0053] Example 3 Graft oxidized alginic acid with a mass fraction of 1.5% of dopamine (the degree of oxidation is 90%, the grafting rate of dopamine is 20%, and the viscosity is 500 mPa·s), 35% acrylamide, and 7% acrylic acid N-hydroxyl Add succinimide ester and 0.010% N,N'-methylenebisacrylamide into purified water, stir at 100-200rpm until completely dissolved, continue stirring for 20min, add 1.6% 2-hydroxy-2-methyl -1-[4-(2-Hydroxyethoxy)phenyl]-1-propanone, 15% acrylic acid and 0.5% calcium chloride, stir at 100-200rpm until the solution is uniform, at a power of 150W, a wavelength of 365nm , pre-polymerized under ultraviolet light for 40 minutes, took out the prepolymer, sprayed 0.5% acrylate PEG-N hydroxysuccinimide ester, 0.25% dopamine, 0.2% acrylamide, 2% acrylate N-hydroxysuccinimide on the surface A mixture of urethane and 0.009% 2-hydroxy-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-propanone, under a UV lamp with a power of 150W and a wavelength of 365nm Polymerize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com