Preparation process of lead plaster of lead-acid storage battery

The invention relates to a lead-acid battery and a preparation process technology, which is applied in the directions of lead-acid battery, lead-acid battery construction, battery electrodes, etc., and can solve the problems of uneven mixing affecting the quality of lead paste, affecting the cycle life of the battery, and reducing the service life of the battery, etc. Achieve the effect of improving mixing processing efficiency, improving mixing and stirring effect, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

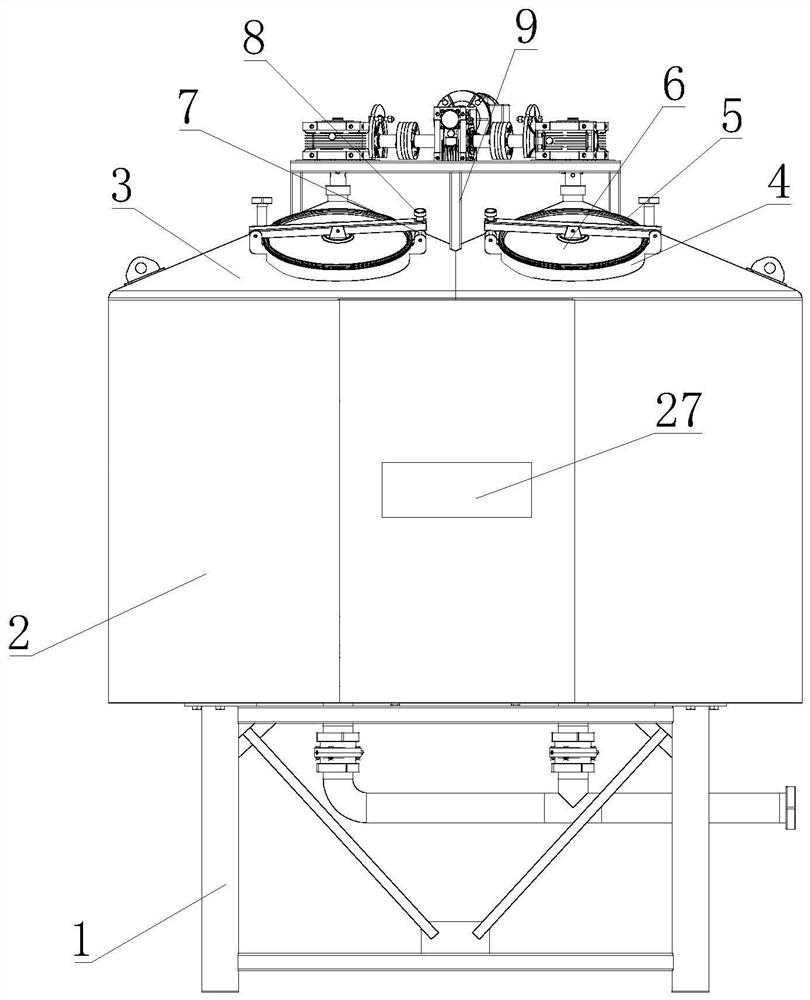

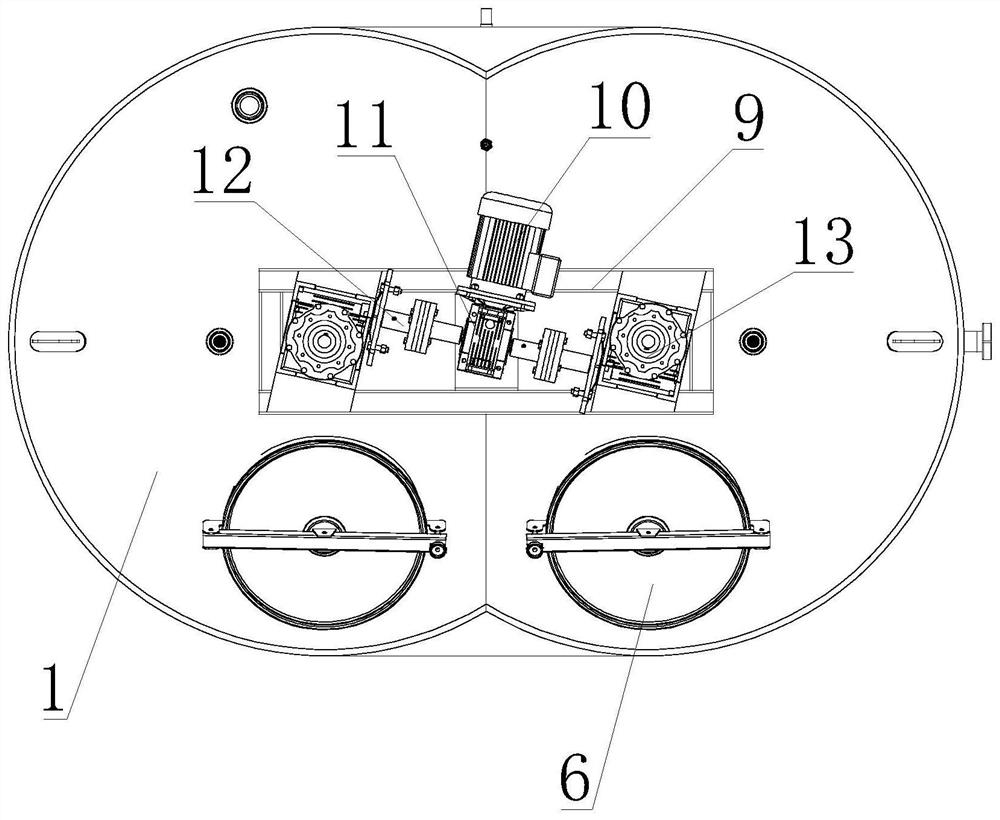

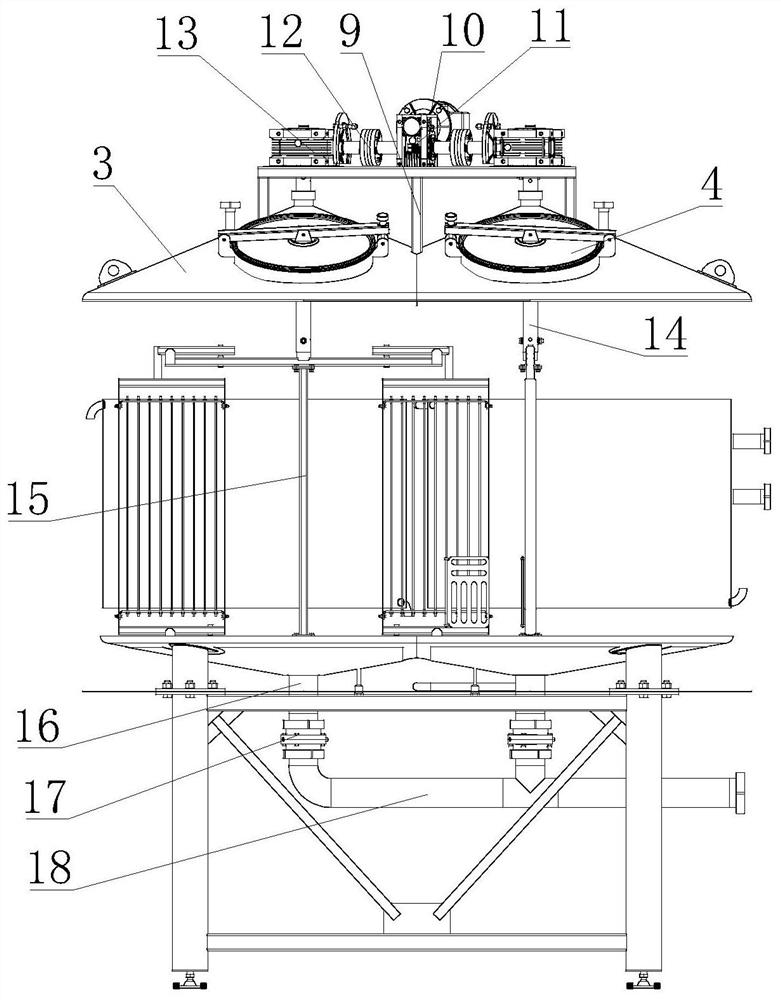

[0032] see Figure 1-5 Shown, a kind of lead-acid battery lead paste preparation process, described lead-acid battery lead paste comprises positive electrode lead paste and negative electrode lead paste; Described positive electrode lead paste comprises the raw material of following weight portion: dilute sulfuric acid 8 parts, deionized water 7 parts part, 0.1 part of polyester staple fiber, 65 parts of lead powder, 1 part of modified graphene; the negative electrode lead paste includes the following raw materials in parts by weight: 10 parts of dilute sulfuric acid, 6 parts of deionized water, 1.2 parts of barium sulfate, wood 0.3 parts of sodium sulfonate, 1.1 parts of carbon black, 0.13 parts of polyester staple fiber, 76 parts of lead powder, and 1.3 parts of modified graphene;

[0033] In the preparation process of the lead paste, the positive lead paste and the negative lead paste are prepared separately, and a mixing and stirring device is used for raw material mixing;...

Embodiment 2

[0050] see Figure 1-5 Shown, a kind of lead-acid battery lead paste preparation process, described lead-acid battery lead paste comprises positive electrode lead paste and negative electrode lead paste; Described positive electrode lead paste comprises the following raw materials by weight: dilute sulfuric acid 10 parts, deionized water 8 part, 0.13 part of polyester staple fiber, 73 parts of lead powder, 1.4 parts of modified graphene; the negative electrode lead paste includes the following raw materials in parts by weight: 12 parts of dilute sulfuric acid, 8 parts of deionized water, 1.4 parts of barium sulfate, wood 0.4 parts of sodium sulfonate, 1.3 parts of carbon black, 0.15 parts of polyester staple fiber, 84 parts of lead powder, and 1.7 parts of modified graphene;

[0051] In the preparation process of the lead paste, the positive lead paste and the negative lead paste are prepared separately, and a mixing and stirring device is used for raw material mixing, and the...

Embodiment 3

[0059] see Figure 1-5 Shown, a kind of lead-acid battery lead paste preparation process, described lead-acid battery lead paste comprises positive electrode lead paste and negative electrode lead paste; Described positive electrode lead paste comprises the raw material of following weight portion: dilute sulfuric acid 12 parts, deionized water 10 part, 0.15 part of polyester staple fiber, 80 parts of lead powder, 1.7 parts of modified graphene; the negative electrode lead paste includes the following raw materials in parts by weight: 14 parts of dilute sulfuric acid, 11 parts of deionized water, 1.5 parts of barium sulfate, wood 0.6 parts of sodium sulfonate, 1.5 parts of carbon black, 0.18 parts of polyester staple fiber, 90 parts of lead powder, 2.1 parts of modified graphene;

[0060] In the preparation process of the lead paste, the positive lead paste and the negative lead paste are prepared separately, and a mixing and stirring device is used for raw material mixing, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap