Bearing pedestal automatic production detection line

An automatic production and inspection line technology, applied in the direction of measuring devices, testing of mechanical parts, testing of machine/structural parts, etc., can solve the problems that the iron filings of the bearing seat cannot be completely removed and affect the detection results, etc., so as to avoid unqualified detection , Improve cleaning efficiency and avoid residual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the various embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and the structural, method, or functional transformations made by those of ordinary skill in the art based on these embodiments are all included in the protection scope of the present invention.

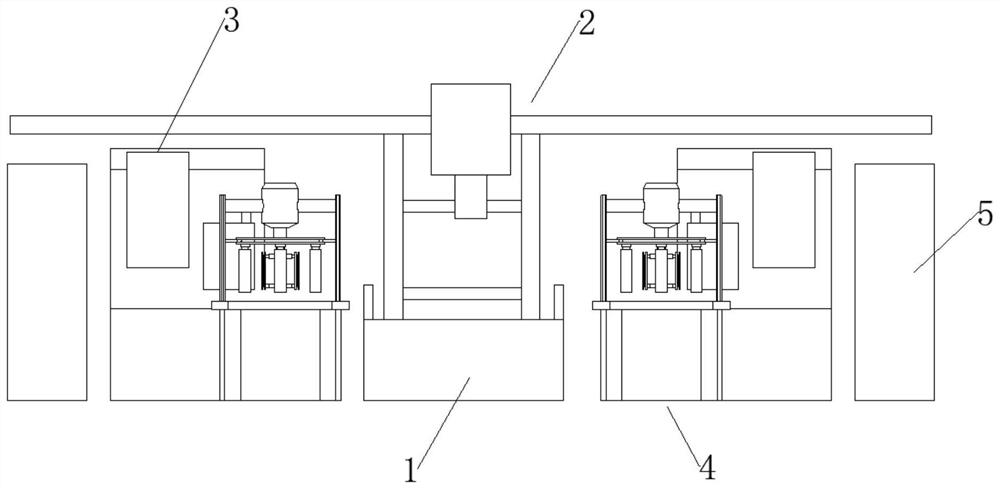

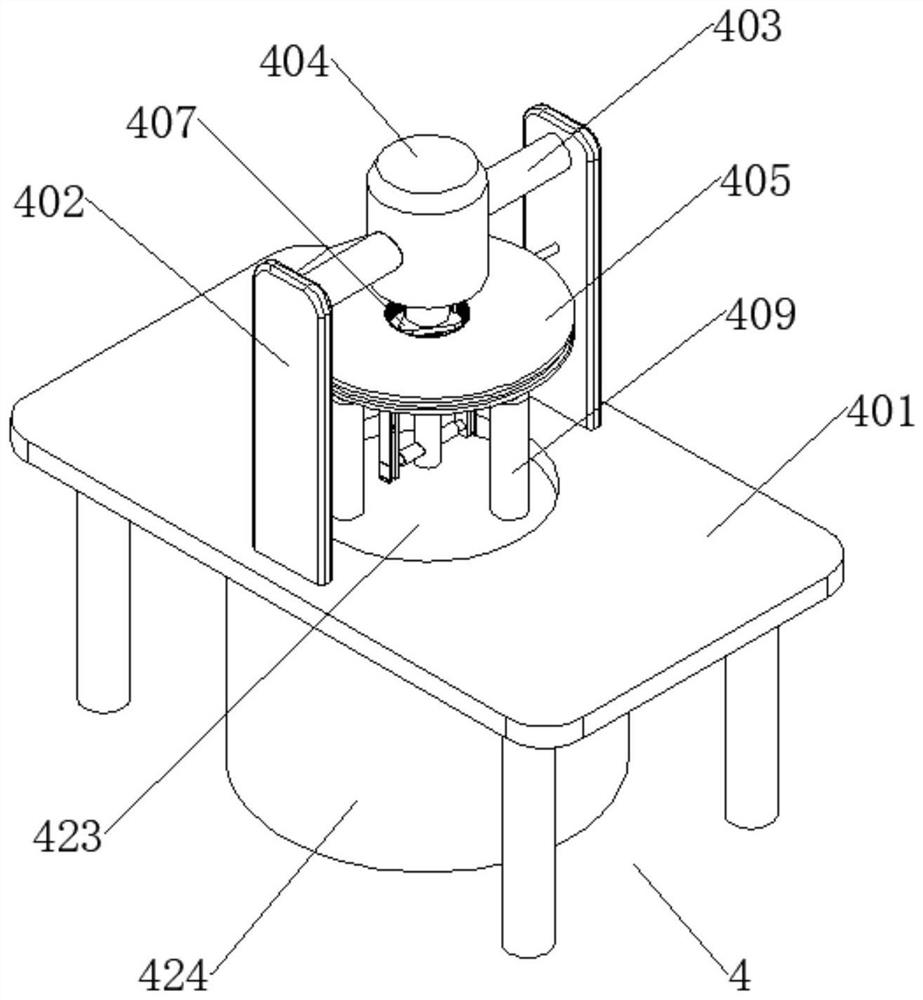

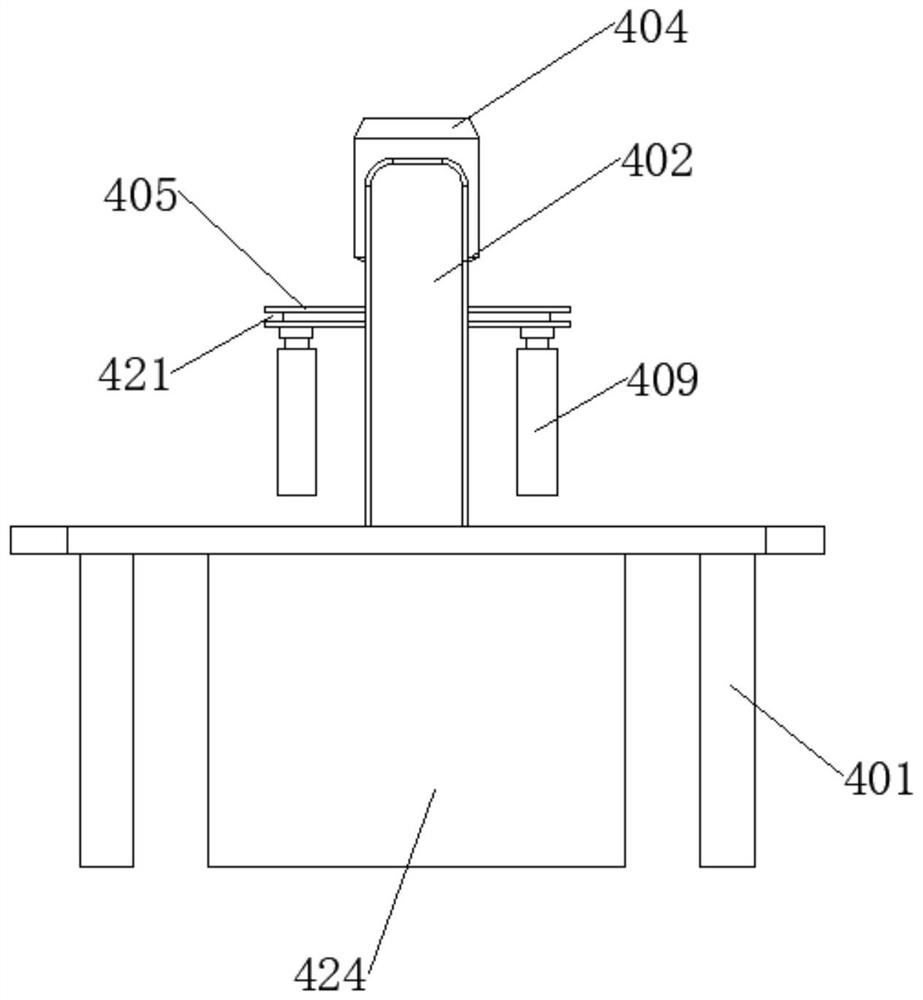

[0033] The invention discloses an automatic production and detection line for a bearing seat. figure 1 As shown, it includes a feeding mechanism 1, a conveying mechanism 2, a processing mechanism 3, a cleaning mechanism 4 and a detection mechanism 5. The feeding mechanism 1 is used for feeding, and the conveying mechanism 2 is used to transport the raw materials of the feeding mechanism 1. The mechanism 3 is used to process and produce the raw material, the cleaning mechanism 4 is used to clean the processed finished product, and the detection mechanism 5 is used to detect the cleane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com