Method for improving mechanical property of laminated armored aluminum alloy friction stir welding joint

A friction stir, welding joint technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as uneven mechanical properties, and achieve the effects of easy access, rapid welding, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

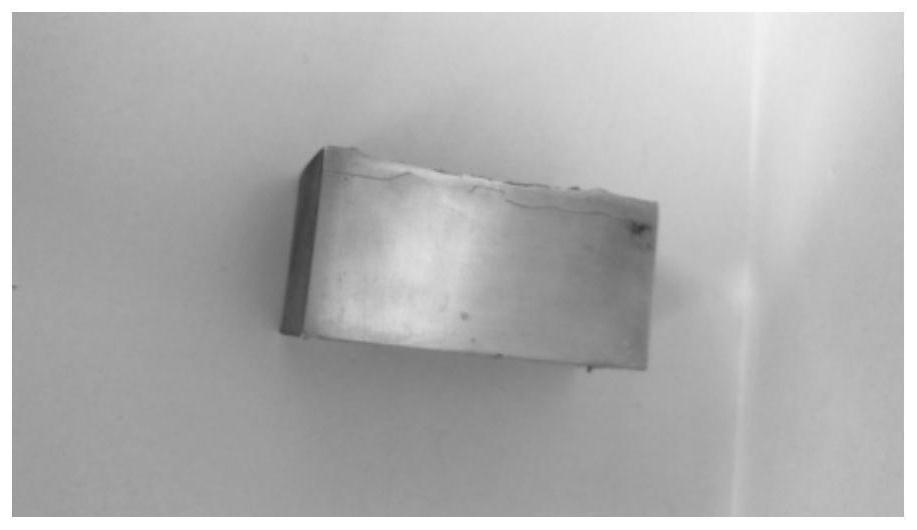

[0035] Two pieces of 7B52 laminated armored aluminum alloy plates with a thickness of 12 mm were welded in a butt joint manner by friction stir welding. When the welding speed is 150mm / min, the rotation speed of the stirring head is 600r / min, and the preheating temperature is 150°C, the tensile strength obtained after welding is 350MPa, and the impact absorption energy is 15.1J.

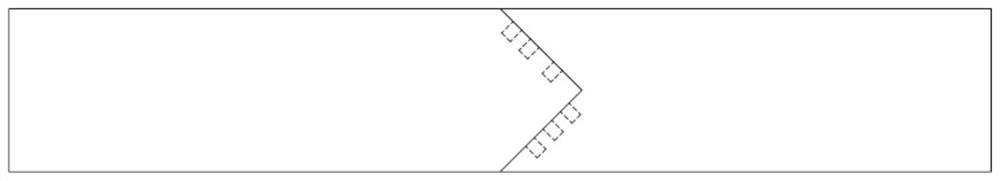

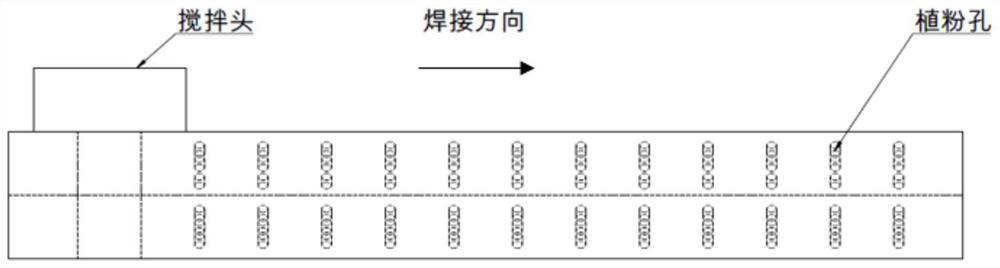

[0036] Adopt the method described in the present invention, the 12mm thick 7B52 laminated armor aluminum alloy machining angle that is used for welding is the bevel of 30 °, process two rows of hole depths at the positions of the first layer and the second layer of the stack along the forward direction of welding 3mm, 2mm hole 1 and filled with TiB particle size 20μm 2 powder, and then use resistance to connect the two plates respectively. Preheat to 150°C from the groove contact surface, and finally use a stirring head with a shaft shoulder diameter of 24mm, a stirring needle root diameter of 12mm, ...

Embodiment 2

[0038] Two pieces of 7B52 laminated armored aluminum alloy plates with a thickness of 16 mm were welded in a butt joint manner by friction stir welding. When the welding speed is 200mm / min, the rotation speed of the stirring head is 500r / min, and the preheating temperature is 150°C, the tensile strength obtained after welding is 375MPa, and the impact absorption energy is 13.8J.

[0039] Adopt the method described in the present invention, to the 16mm thick 7B52 laminated armor aluminum alloy processing angle that is used for welding be the groove of 45 °, when a row of hole depth 4mm is processed at the position of the first layer of the laminate along the welding advance direction, the aperture 2.5mm powder planting holes filled with TiB with a particle size of 20μm 2 powder, and then use resistance to connect two plates respectively. Preheat to 150°C from the groove contact surface, and finally use a stirring head with a shaft shoulder diameter of 32mm, a stirring needle ro...

Embodiment 3

[0041] Two pieces of 20mm thick 7B52 laminated armored aluminum alloy plates were welded by friction stir welding in a butt joint mode. When the welding speed is 50mm / min, the rotation speed of the stirring head is 500r / min, and the preheating temperature is 150°C, the tensile strength obtained after welding is 347MPa, and the impact absorption energy is 11.5J.

[0042]By adopting the method of the present invention, the 20mm thick 7B52 laminated armor aluminum alloy used for welding is processed with a groove angle of 45°, and a row of holes with a depth of 3mm and an aperture of 2mm are processed at the position of the first layer of the laminate along the welding advance direction. The powder-planting holes are filled with TiB with a particle size of 10 μm 2 powder, and then use resistance to connect two plates respectively. Preheat to 150°C from the groove contact surface, and finally use a stirring head with a shaft shoulder diameter of 36mm, a stirring needle root diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com