Online detection method for laser deep penetration welding defects and detection device

A technology of laser deep penetration welding and detection method, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems that the accuracy and robustness are difficult to meet, and does not consider the complexity of the small hole contour structure, etc., to achieve Effect of improving accuracy and robustness, reducing time and cost, increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. According to the following description, the purpose, technical solution and advantages of the present invention will be more clear. It should be noted that the described embodiments are preferred embodiments of the present invention, but not all embodiments.

[0042] An online detection method for laser deep penetration welding defects, comprising the following steps:

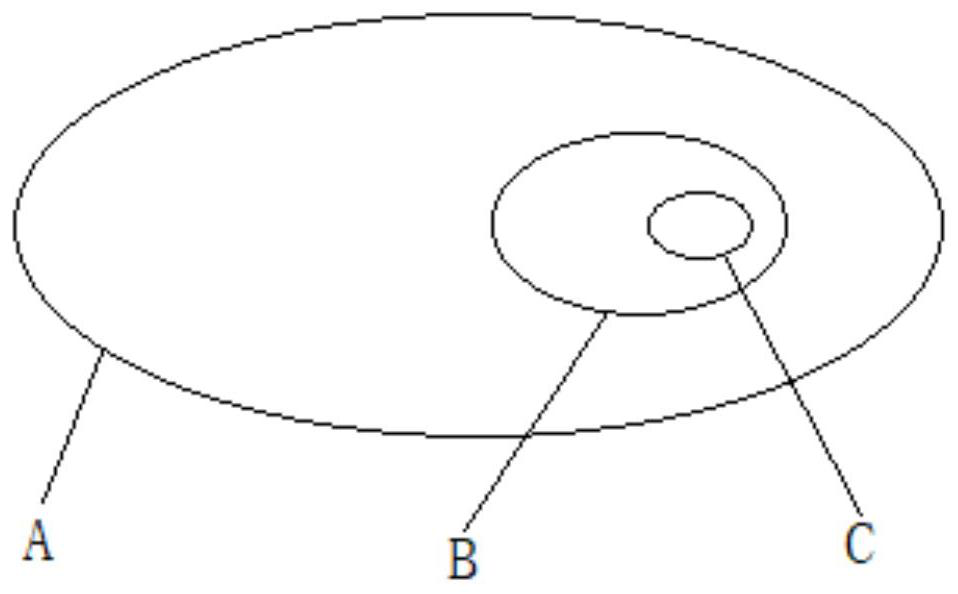

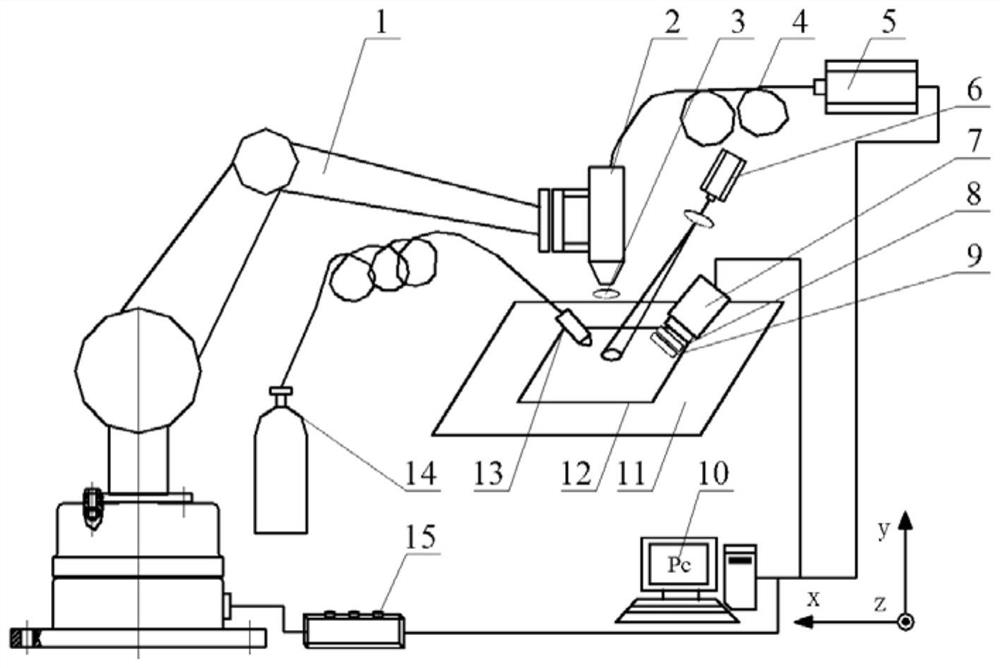

[0043] S1. During the welding process, through the imaging system, the images formed during welding such as figure 1 Real-time extraction and storage of the contour images of the molten pool small hole B and the penetration hole C shown;

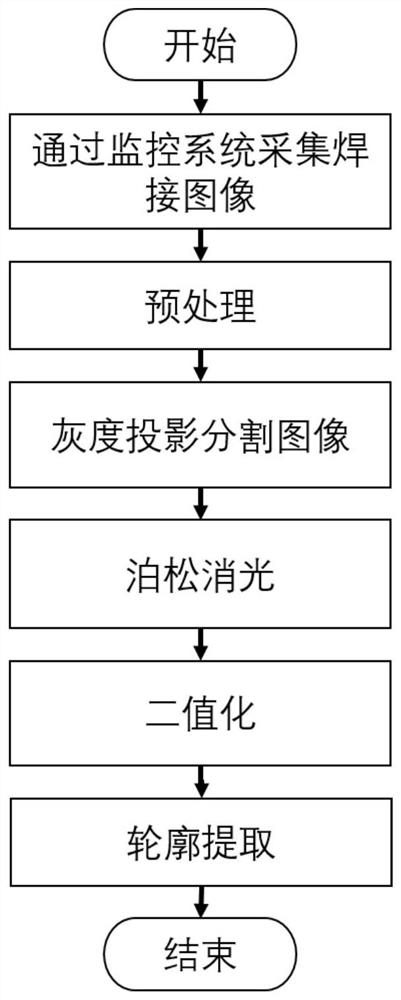

[0044] S2. By collecting welding images of different types of welding defects, extracting their contour features to form different data sets, calculating the curvature descriptor of the boundary contour as a feature of welding qualit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com