A method and device for online adjustment of weld opening angle of pipeline steel pipe

An adjustment method and an opening angle technology, applied in the field of on-line adjustment of the opening angle of pipeline steel pipe welds, can solve problems such as waste, increased production costs, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

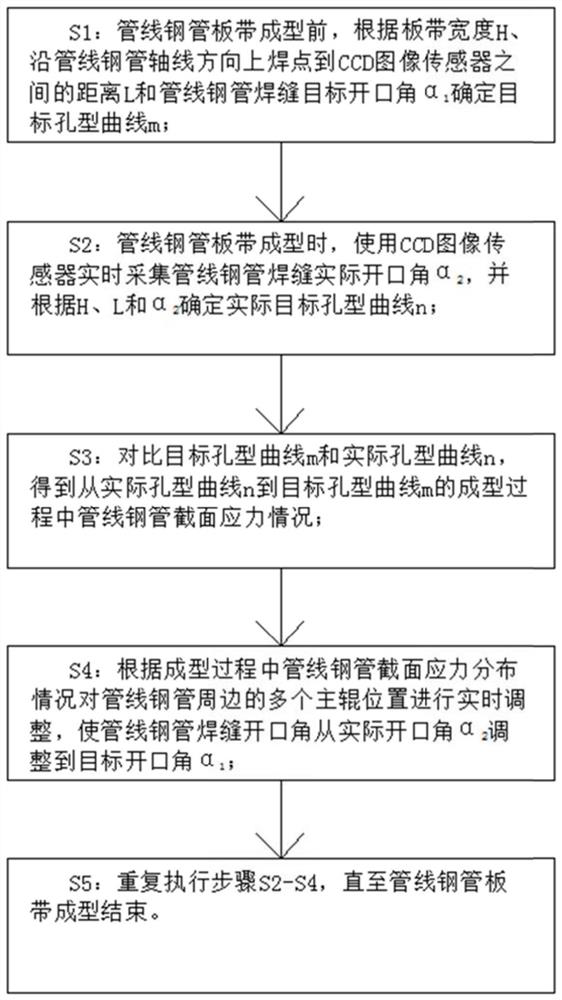

Method used

Image

Examples

Embodiment 1

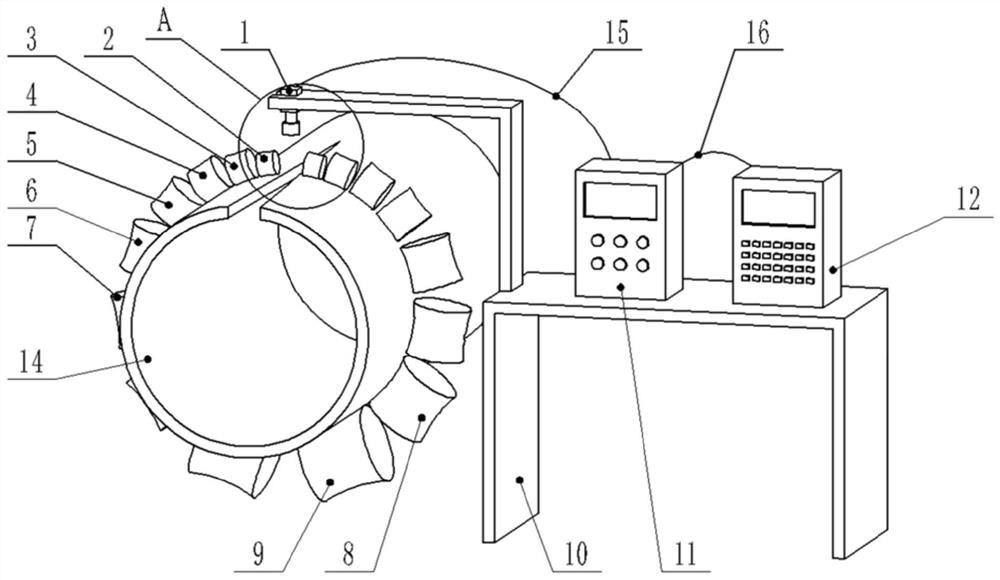

[0043] In this embodiment, eight roll pairs are set, and along the circumferential direction of the pipeline steel pipe from the weld, they are the first roll pair 2, the second roll pair 3, the third roll pair 4, the fourth roll pair 5, and the fifth roll pair. The roll pair 6, the sixth roll pair 7, the seventh roll pair 8, and the eighth roll pair 9, and the eight roll pairs are in the same radial plane of the pipeline steel pipe.

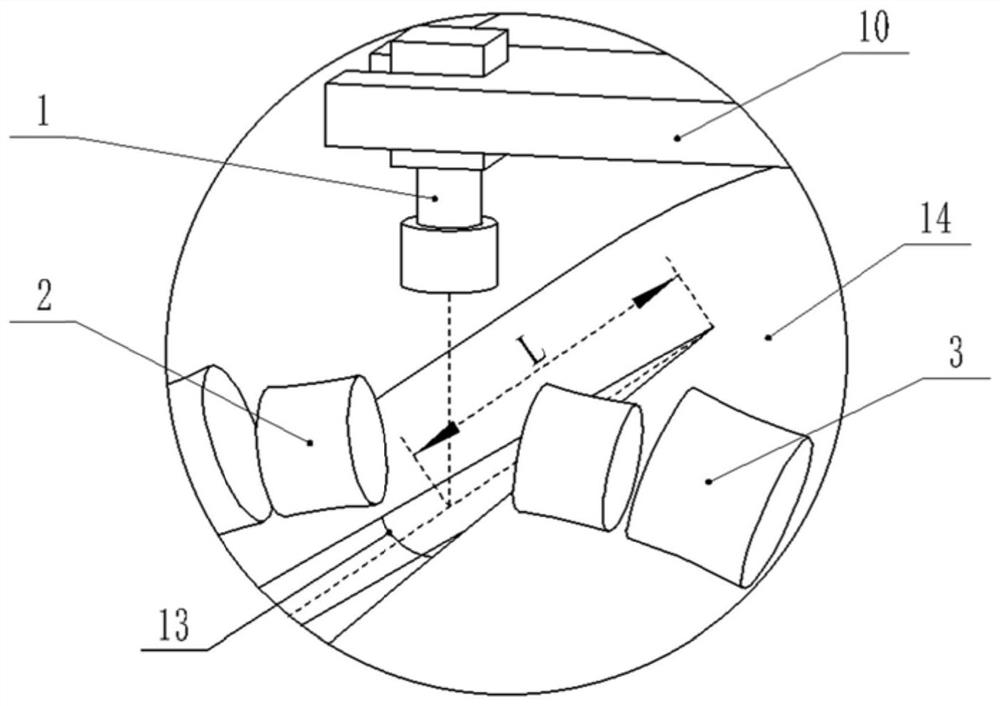

[0044] by Take the second-pass forming of the fine forming stage of the pipeline steel pipe 14 strip forming process as an example. The working process of the device is roughly as follows: Before the pipeline steel pipe 14 strip is formed, input the strip width 760 mm and the steel pipe along the pipeline 14 into the information processing system 11. The distance between the welding spot and the CCD image sensor 1 in the axial direction is 320 mm, and then input the target opening angle α of the weld seam 13 of the pipeline steel pipe to the in...

Embodiment 2

[0047] Nine pairs of rollers are set in this embodiment. Compared with Embodiment 1, the eighth roller pair is reduced in the present invention, and a group of third roller pair 4 and second roller pair 3 is added.

[0048] by Take the third pass forming in the fine forming stage of the pipeline steel pipe strip forming process as an example. The working process of the device is roughly as follows: Before the pipeline steel pipe 14 strip is formed, input the strip width 760mm and the width along the pipeline steel pipe 14 axis into the information processing system 11 The distance between the welding spot and the CCD image sensor 1 in the direction is 200 mm, and then input the target opening angle α of the pipeline steel pipe 14 weld seam 13 to the information processing system 11 1 is 3°, the information processing system 11 obtains the diameter D of the target pass curve m142 through calculation 1 It is 245.25mm, and then generates the target pass curve m142. During the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com