Circuit board processing device for electrical components

A technology for processing devices and electrical components, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of convenient and fast operation and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

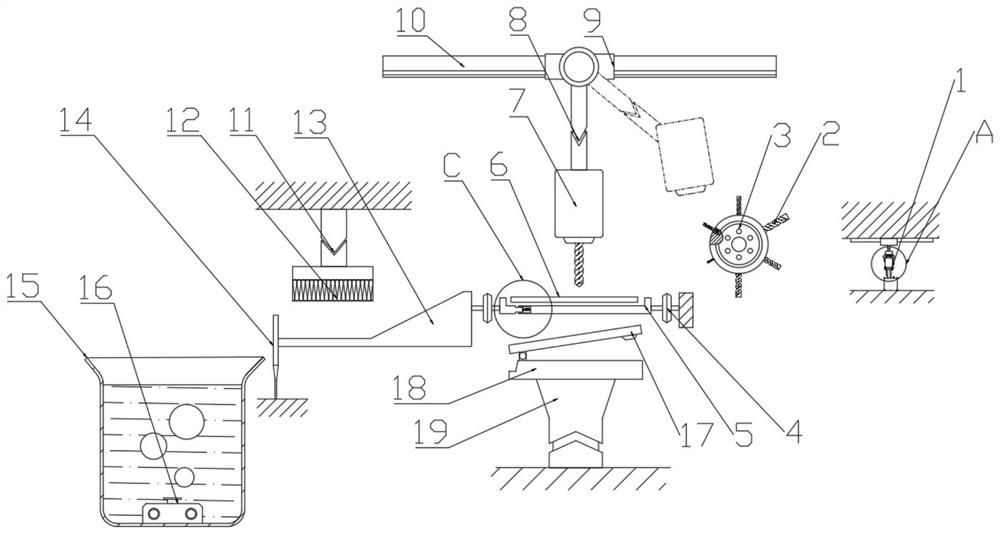

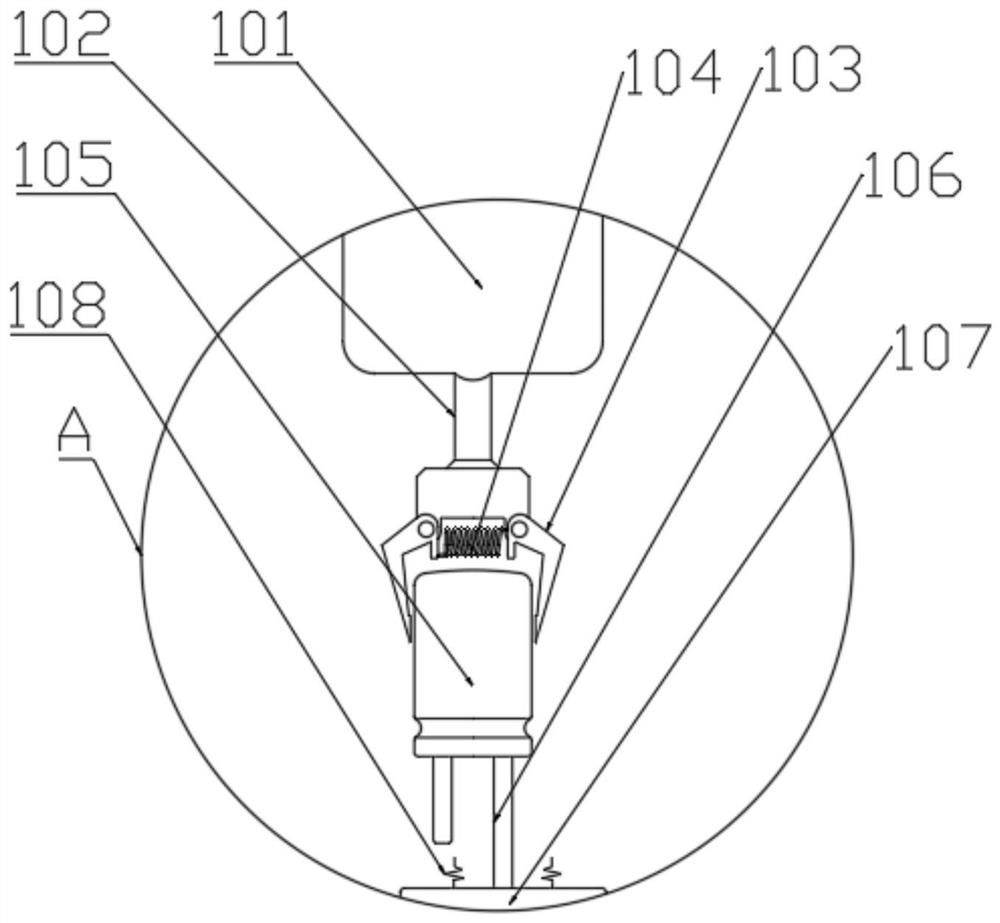

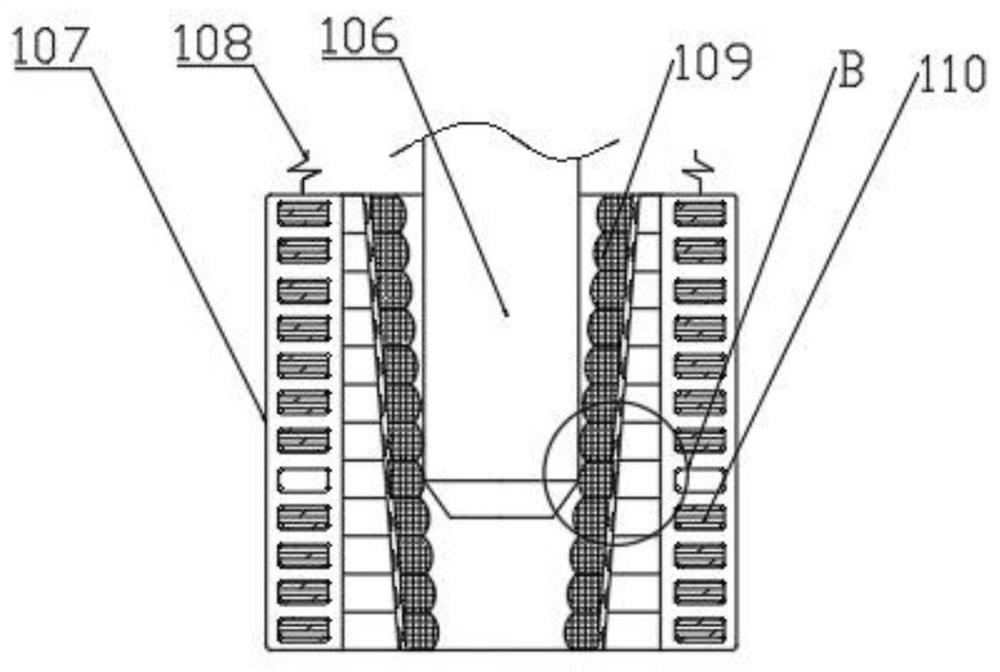

[0026] see also Figure 1-7 A circuit board processing device for electrical components comprises a drill 2 and a drill drive module 7, wherein the drill 2 is connected to the drill drive module 7, and the drill drive module 7 drives it to drill holes on the surface of the circuit board 6; the side of the drill drive module 7 is provided with a pre-judgment mechanism 1 for selecting the specifications of the drill 2; the pre-judgment mechanism 1 comprises a clamping module and a pre-judgment module; the clamping module comprises a telescopic rod 101 and a claw seat 102, One end of the telescopic rod 101 is slidably arranged on the wall, and the other end is fixedly connected with one end of the claw base 102, and the other end of the claw base 102 is rotatably connected with two claws 103, which are elastically connected by a first spring 104. The pre-judgment module includes a pre-judgment housing 107 and a movable block 109, and the pre-judgment housing 107 is arranged below the ...

Embodiment 2

[0032] In order to further improve the processing efficiency of the circuit board 6, an improvement is added on the basis of Embodiment 1. The improvement is as follows: Please refer to Figure 1-7 A drill driving module 7 is arranged at the side of the cutter head 3, a connecting hole matched with the drill 2 is arranged below the drill driving module 7, a driving block 20 is slidably arranged at the side, and a rocker arm 8 is rotatably connected to the driving block 20, and the rocker arm 8 is a telescopic arm with telescopic function; The rocker arm 8 is rotatably connected to the slide block 9, and the slide block 9 is slidably connected to the slide bar 10, which is fixedly connected to the wall.

[0033] The drill pin driving module 7 can be divided into three states in the whole process. The first state is the working state, that is, driving the drill pin 2 for drilling; Secondly, the tool changing state, that is, with the cooperation of the driving block 20, the rocker arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com