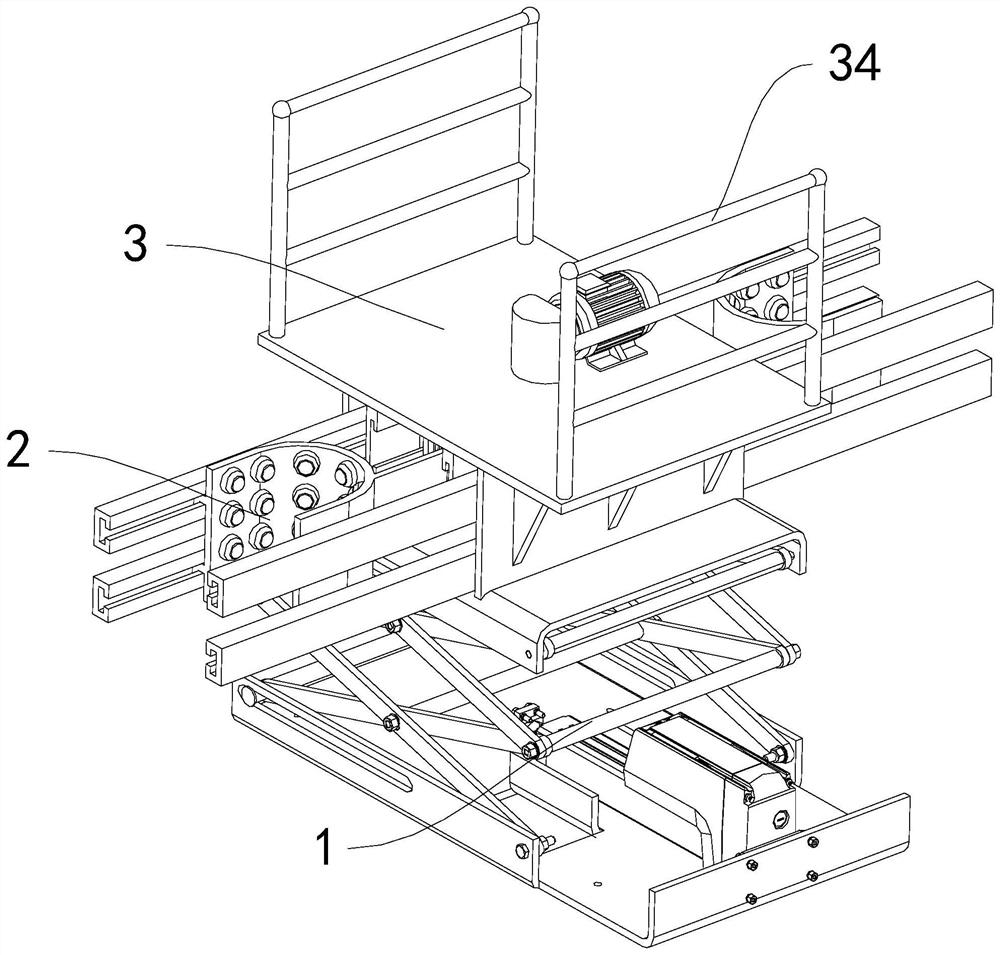

Lifting type power equipment overhauling device and using method thereof

A technology for power equipment and maintenance devices, which is applied in the direction of hoisting equipment safety devices and hoisting devices, which can solve the problems of low maintenance efficiency and low operation safety, and achieve the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

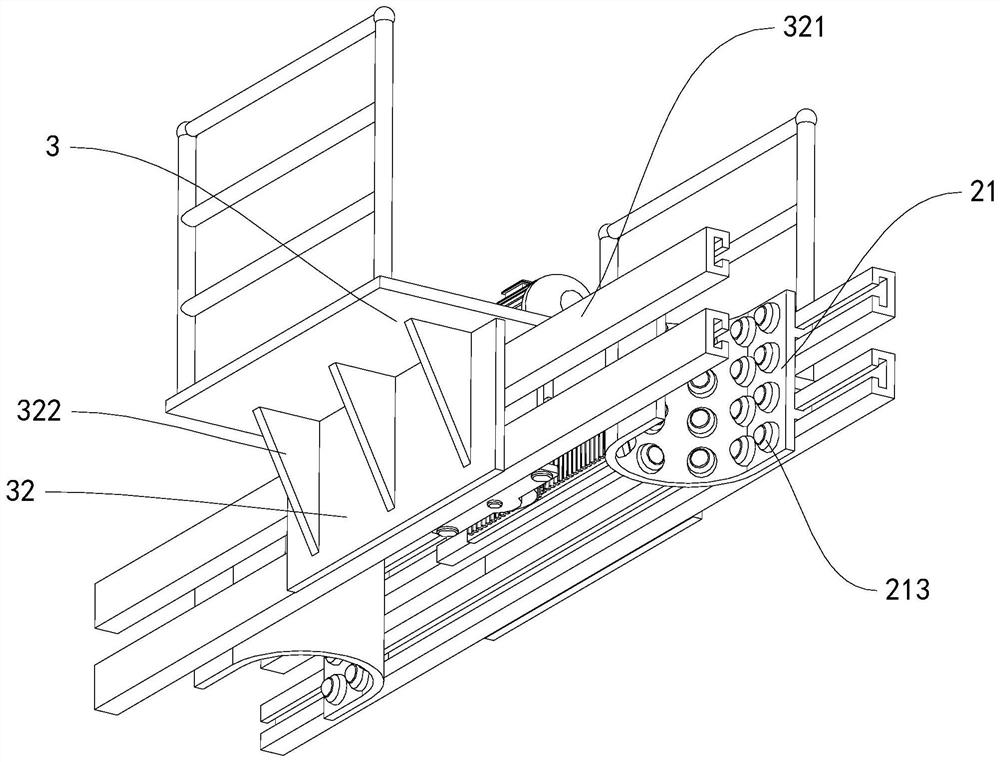

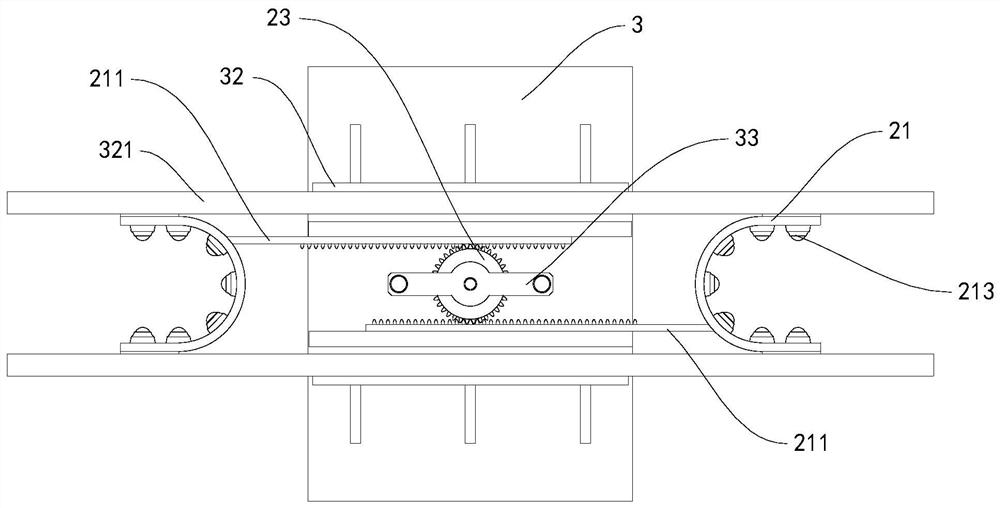

[0043] Embodiment 1: the bottom of the operating platform 3 is provided with a fixed mounting plate 32, and the fixed mounting plate 32 is provided with two, and the two fixed mounting plates 32 are symmetrically arranged on both sides of the bottom of the operating platform 3, two The opposite direction of the fixed mounting plate 32 is respectively provided with two limit chute 321, and the two outer end surfaces of the two U-shaped limit grooves 21 are respectively provided with two limit slides 212, which are located in the U-shaped position. The limit sliders 212 on both sides of the U-shaped limit groove 21 are respectively limited to the two limit chute 321, and the moving direction of the U-shaped limit groove 21 on both sides can be limited by the set limit chute 321 , so that the connection strength between the limiting device 2 and the operating platform 3 can be increased, and the limiting stability of the limiting device 2 can be improved.

Embodiment 2

[0044] Embodiment 2: The limiting chute 321 is composed of a middle fixing plate 41, a side folding plate 42, a hydraulic cylinder fixing plate 43 and a folding hydraulic cylinder 44, and the middle fixing plate 41 is installed on the fixed mounting plate 32, There are four side end folding plates 42, and the four side end folding plates 42 are connected to both sides of the two middle fixing plates 41 respectively, and the side end folding plates 42 can be carried out on the middle fixing plate 41. Folding toward the outer end direction, the hydraulic cylinder fixing plates 43 are provided with two and are respectively vertically fixed on the two fixed mounting plates 32, the folding hydraulic cylinders 44 are provided with four, and the four folding hydraulic cylinders One end of 44 is respectively connected to the two ends of the two hydraulic cylinder fixing plates 43, and the other ends of the four folding hydraulic cylinders 44 are respectively connected to the four side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com