Rapid construction method of continuous rigid frame bridge

A construction method and rigid-frame bridge technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of increasing the size of the lower structure and the amount of steel bars, increasing the amount of materials, and increasing construction costs, so as to reduce the amount of materials and Construction cost, improved stress state, and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

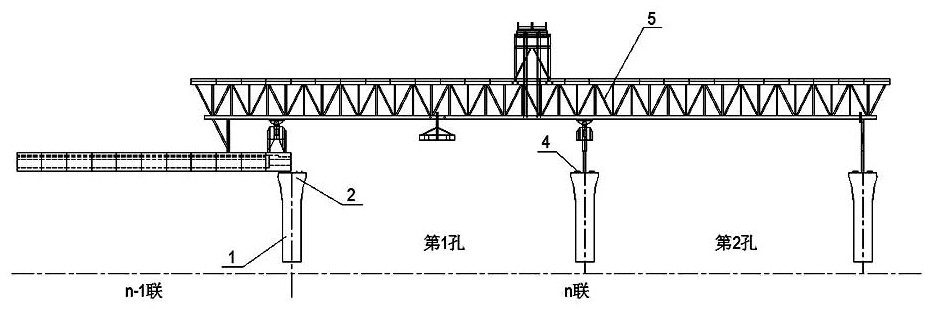

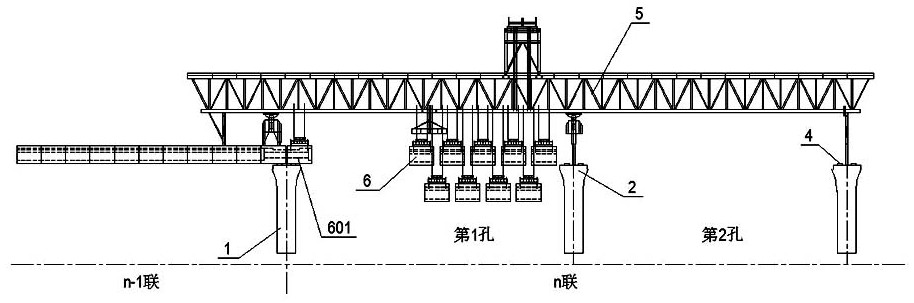

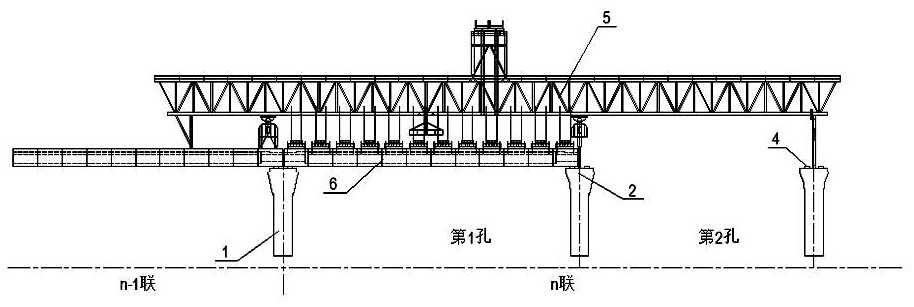

[0041] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific construction processes are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

[0042] Such as Figure 1-15 Shown, the rapid construction method of continuous rigid frame bridge of the present invention, comprises the steps:

[0043] The first step is to construct the bridge substructure of the single-pile and single-column structure including the pile foundation 1 and the pier 2. Specifically, after the drilling is completed, the pile foundation reinforcement cage bound in the steel bar processing plant will be lowered to the design position. Pour concrete to complete the construction of pile foundation 1. The steel skeleton and formwork of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com