Braking system for vertical axis wind turbine and wind turbine

A technology of wind power generator and braking system, which is applied in the direction of wind power generator, wind power motor, wind power motor combination and other directions at right angles to the wind direction, which can solve the problems such as difficult to achieve braking effect, difficult to achieve braking, small braking torque, etc., to achieve Improve safety and reliability, improve braking torque, and increase the effect of braking arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

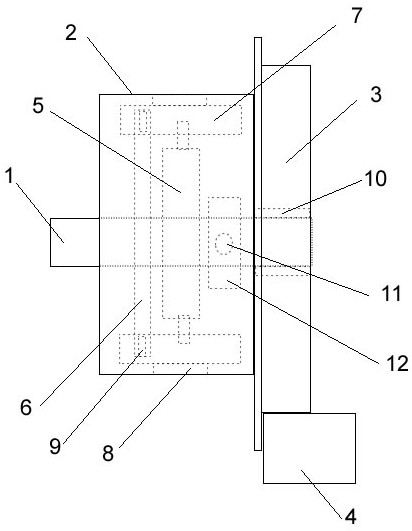

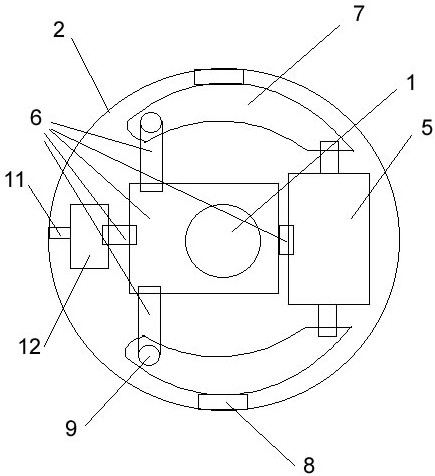

[0056] Such as figure 1 and 2 , is a structural schematic diagram of an internal expansion brake. The advantage of this brake structure is that it has a large braking force and is used for the braking system of a vertical axis wind turbine. The braking system described in this embodiment includes rollers 3, couplings 6, Brake hoop 2, brake solenoid valve 5, brake brake arm 7, brake brake arm bearing 9, brake brake arm shaft 13, friction plate 8, safety pin solenoid valve 12 and safety pin 11. The brake device 2 is a brake hoop 2, which is fixedly installed on the roller 3, and is installed by welding or flange or any known method; the roller 3 is installed on the roller bearing 10, and the roller bearing 10 is installed on the wheel shaft 1, and the wheel shaft 1 is fixedly installed On the wind wheel; the brake solenoid valve 5 is fixedly installed on the wheel shaft 1 through the coupling 6 and can control the brake arm 7, and the other end of the brake arm 7 is fixedly ins...

Embodiment 2

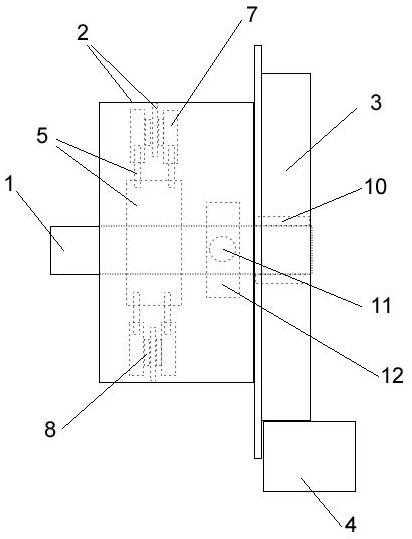

[0066] Such as image 3 , 4 As shown in and 6, the braking system described in this embodiment includes a brake disc 2, a brake solenoid valve 5, a brake disc 7, a friction plate 8, a safety pin solenoid valve 12 and a safety pin 11; the brake device 2 is The brake disc, the brake disc 2 is a circular disc welded on the brake hoop, the brake hoop is fixedly installed on the roller 3, the roller 3 is installed on the bearing 10, the bearing 10 is installed on the wheel shaft 1, and the wheel shaft 1 is fixedly installed on the wind wheel; the brake solenoid valve 5 is fixedly installed on the wheel shaft 1 through the coupling 6 and can control the brake disc 7, the brake disc 7 is fixedly installed on the brake solenoid valve 5, and the brake brake A friction plate 8 is arranged on the boom 7 ; a safety pin solenoid valve 12 is fixedly installed on the wheel shaft 1 through a coupling 6 and can control the safety pin 11 . The coupling 6 is a well-known product in the wind po...

Embodiment 3

[0068] Such as Figure 7 and 13 as shown, Figure 7 It is a front view schematic diagram of the overall structure principle of a vertical axis wind power generator according to the present invention; the wind wheel 23 is composed of a support arm and blades, and a roller 3 is installed under the wind wheel support arm, and the roller 3 is supported on an annular level on the track 4, and can roll on the circular horizontal track 4, which is fixedly installed on the track support member 14; the wind wheel 23 is connected with the generator system 16 through the wind wheel main shaft or the generator main shaft 15.

[0069] Figure 13 It is a schematic diagram of the connection structure between the wind wheel 23 and the roller 3 and the cross section of the circular horizontal track 4; the connecting member 22 is connected on the supporting wing of the wind wheel 23, and the connecting member 22 and the supporting wing of the wind wheel 23 are all steel structures. It can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com