An optical fiber measurement system for bending degree of scraper machine

An optical fiber measurement and bending technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of unreasonable laying method of distributed optical fiber sensing system, inaccurate measurement results, nonlinear problems, etc., to achieve enhanced application performance and operability, increase the frequency sweep range, and reduce the effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

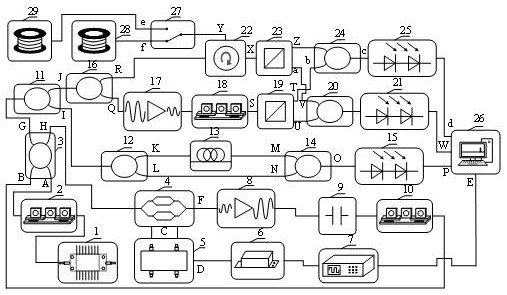

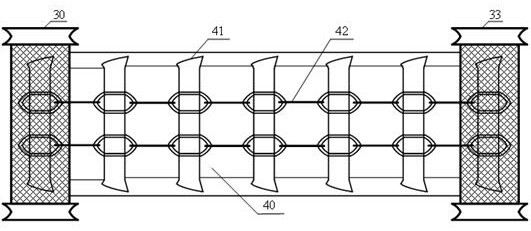

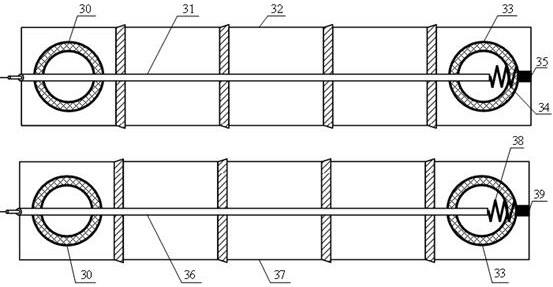

[0015] refer to figure 1 , the present invention provides a fiber optic measurement system for the curvature of a scraper machine, including: a frequency-stabilized laser 1, a first fiber coupler 3, an IQ modulator 4, an electric bridge 5, a microwave source 6, a signal generator 7, a second Fiber coupler 11, third fiber coupler 12, delay fiber 13, fourth fiber coupler 14, first photodetector 15, fifth fiber coupler 16, adjustable optical attenuator 17, first polarization beam splitter 19. The sixth optical fiber coupler 20, the second photodetector 21, the optical circulator 22, the second polarization beam splitter 23, the seventh optical fiber coupler 24, the third photodetector 25, the computer 26, the optical switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com