Method, device and equipment for predicting residual service life of magnetic levitation system and medium

A technology of life prediction and magnetic levitation, which is applied in design optimization/simulation, computer-aided design, special data processing applications, etc., can solve problems such as difficult to capture, complex physical failure process, and reduce the accuracy of remaining service life prediction, so as to improve the accuracy degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In the prior art, the remaining service life of the maglev system is predicted by establishing a physical model. Since an accurate physical model cannot be established for a complex system, the accuracy of the remaining service life prediction of the maglev system is reduced. In order to overcome the above problems, the present application proposes a hybrid prediction method for the remaining service life of the maglev system, which can improve the accuracy of the prediction of the remaining service life of the maglev system.

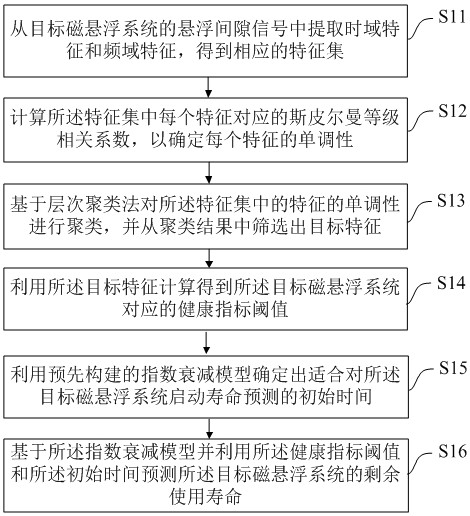

[0055] The embodiment of the present invention discloses a method for predicting the remaining service life of a magnetic levitation system, see figure 1 As shown, the method may include the following steps:

[0056] Step S11: Extract time-domain features and frequency-domain features from the levitation gap signal of the target maglev system to obtain a corresponding feature set.

[0057] In this embodiment, first extract the time-domain featur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com