Core column distributing device and system for stacked transformer iron cores

A material distributing device and transformer technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic cores, electrical components, etc., can solve the problems of not being able to grasp the first-level sheet materials, boring and repetitive labor, etc., and achieve improved machine grasping efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

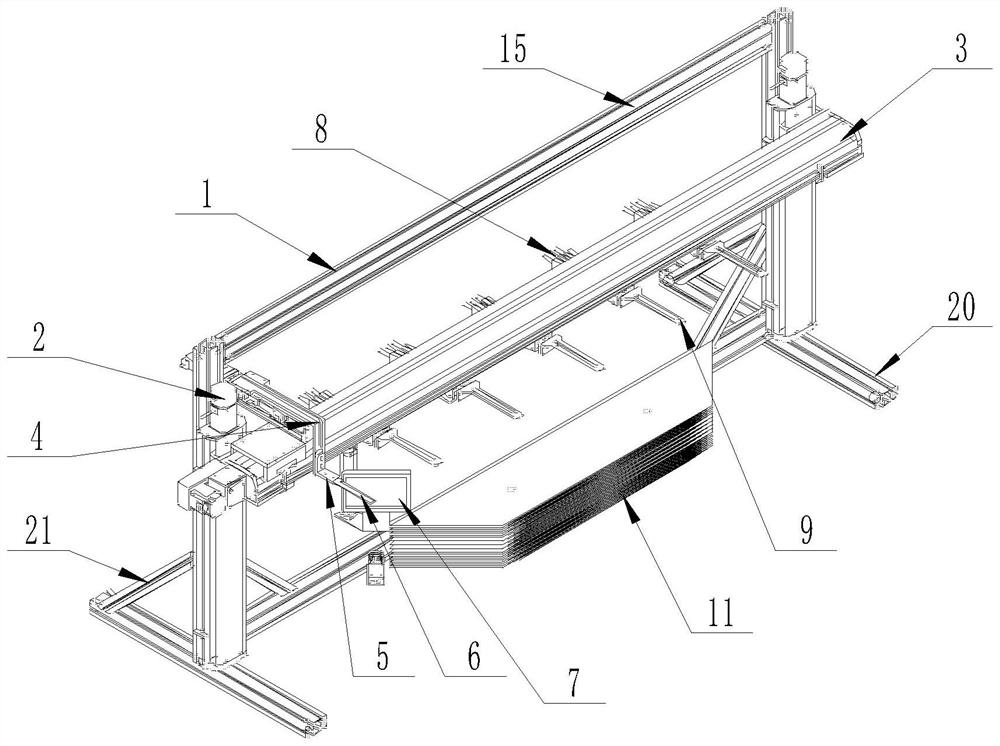

[0039] refer to Figure 1-7 A transformer stacked iron core column splitting device is shown, including

[0040] Three-axis mechanism fixing frame 1;

[0041] The XYZ three-axis mechanism 3, the XYZ three-axis mechanism 3 is connected to one side of the three-axis mechanism fixing frame 1;

[0042] The material distribution blade mechanism is connected to the XYZ three-axis mechanism 3;

[0043] An iron core column support frame, the iron core column support frame is arranged on one side of the three-axis mechanism fixing frame 1;

[0044] A visual recognition mechanism 7, the visual recognition mechanism 7 is connected to the support frame of the iron core column;

[0045] The supporting mechanism, the supporting mechanism is fixedly connected to the XYZ three-axis mechanism 3;

[0046] The controller is electrically connected with the XYZ three-axis mechanism 3, the visual recognition mechanism 7 and the material supporting mechanism respectively.

[0047]The XYZ three-...

Embodiment 2

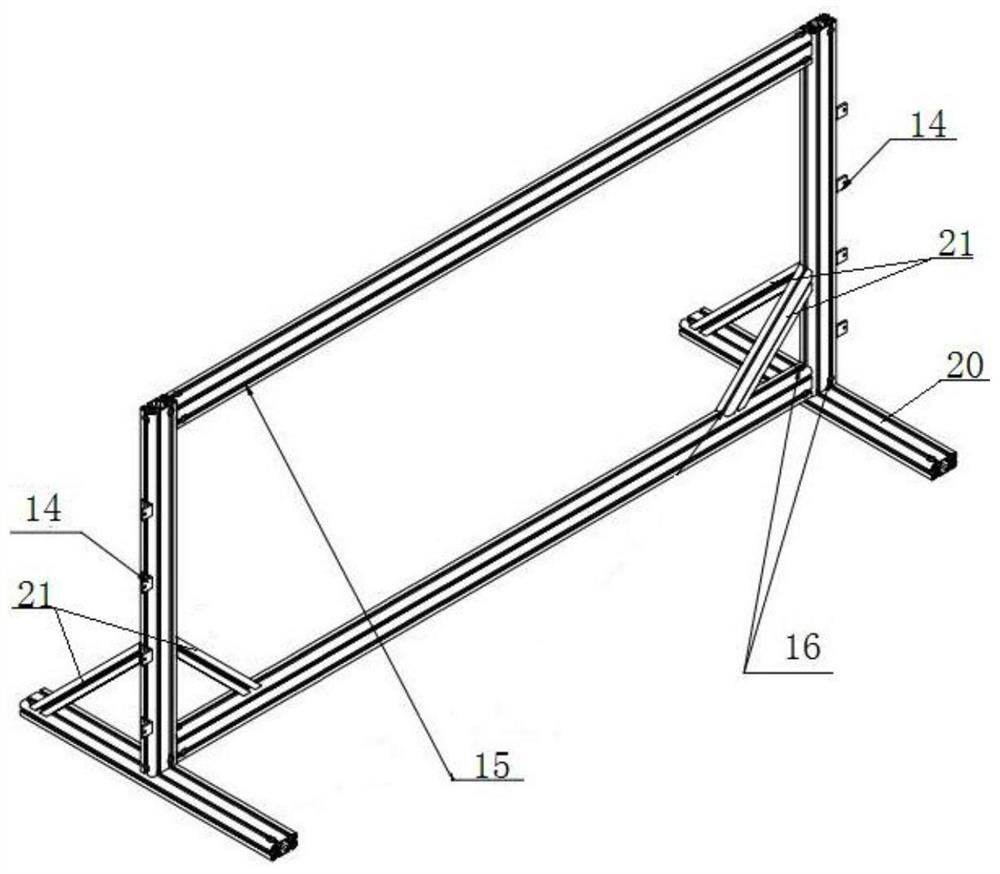

[0050] refer to figure 1 and figure 2 The shown transformer stacked iron core column splitting device is based on the first embodiment: the three-axis mechanism fixing frame 1 includes a support frame 15, a horizontal strut 20, a diagonal strut 21 and a corner connection block 14. The support frame 15 is a rectangular frame structure, and the support frame 15 is set vertically; the horizontal struts 20 are provided with two, and the two horizontal struts 20 are respectively horizontally connected to both ends of the bottom of the horizontal struts 20 and connected to the support frame respectively. The sides of 15 are vertical; the diagonal struts 21 are provided with four, two of which are fixedly connected to the two bottom corners inside the support frame 15 with oblique symmetry respectively, and the other two are arranged in parallel and connected with the three-axis mechanism fixing frame 1 respectively. The two vertical sides and the horizontal strut 20; the corner co...

Embodiment 3

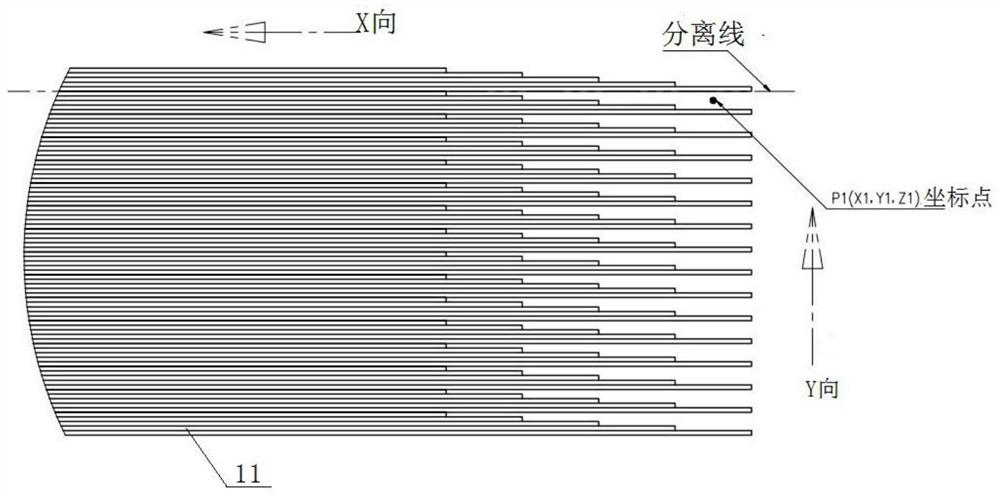

[0055] refer to figure 1 and Figure 5 The illustrated transformer stacked iron core column distribution device is based on the first embodiment: the XYZ three-axis mechanism 3 includes an X-axis rod 17, two Y-axis rods 18, a Z-axis rod 19 and three axis servo drive system 2; the X-axis rod 17, the Y-axis rod 18 and the Z-axis rod 19 are provided with slideways along the axial direction, and slide blocks are connected on the slideways; the two Y-axis rods 18 are parallel And vertically connected on the three-axis mechanism fixing frame 1; the X-axis rod 17 is arranged horizontally, and the two ends of the X-axis rod 17 are respectively connected with the sliders on the two Y-axis rods 18; the Z-axis rod 19 is connected to the slider of the X-axis rod 17, and is vertically arranged with the Y-axis rod 18 and the X-axis rod 17; The slider on the Z-axis rod 19 is connected to drive the sliding of the slider on the X-axis rod 17, the Y-axis rod 18 and the Z-axis rod 19; the visu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com