Automatic corn thresher for processing selenium-enriched nutritional tender corn paste japonica

A technology of tender corn and thresher, applied in threshing equipment, application, agricultural machinery and implements, etc., can solve the problems of inconvenient discharge, low efficiency, stuck corn cob, etc., to avoid internal stuck, good protection, The effect of high discharge purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

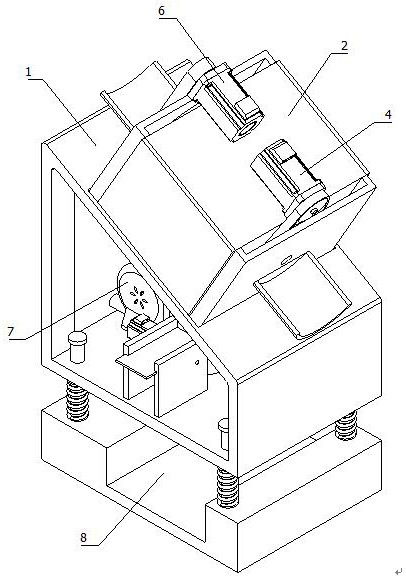

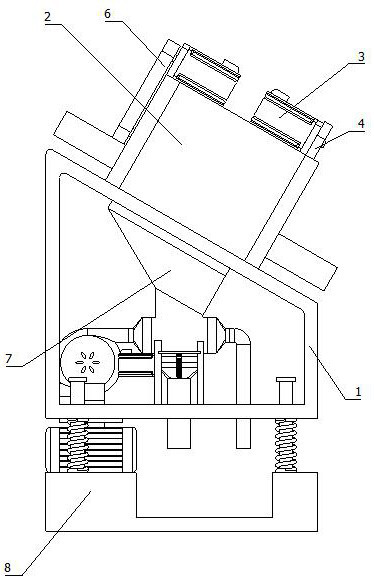

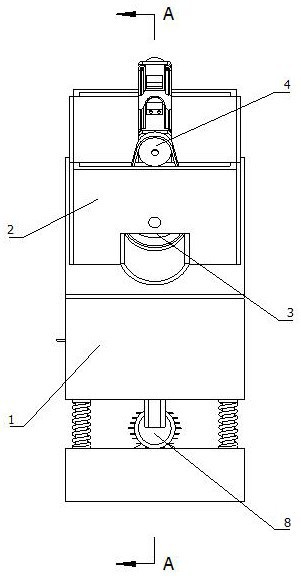

[0083] Such as Figure 1 to Figure 4 As shown, an automatic corn thresher for processing selenium-enriched nutritious tender corn paste, including a mounting frame 1, a threshing box 2, a threshing cylinder 3, a first rotary drive mechanism 4, a threshing rotor 5, a second rotary drive Mechanism 6, bran screening mechanism 7 and vibration mechanism 8;

[0084] The mounting frame 1 can be installed on the vibrating mechanism 8 movable along the vertical direction, and is used for installing the threshing box 2 and the chaff screening mechanism 7;

[0085] The threshing box 2 is obliquely installed on the top of the installation frame 1, and is used for installing the threshing cylinder 3 and the threshing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com