Device for automatically taking coconut water and using method of device

A coconut water, automatic technology, applied in the application, agricultural gas emission reduction, shelling and other directions, can solve the problems of irregular coconut shell crushing, inability to maintain quality and quantity, reduce utilization rate, etc. Valuable, avoid air contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the technical content of the present invention, specific embodiments are provided below, and the present invention is further described in conjunction with the accompanying drawings.

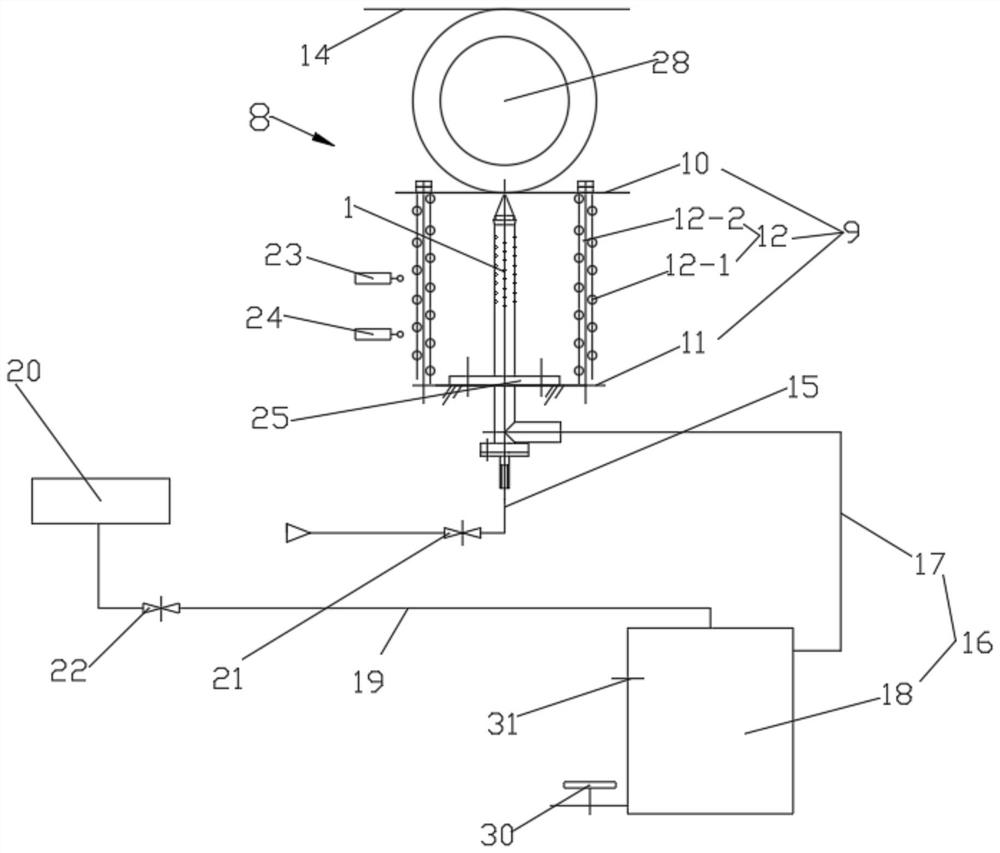

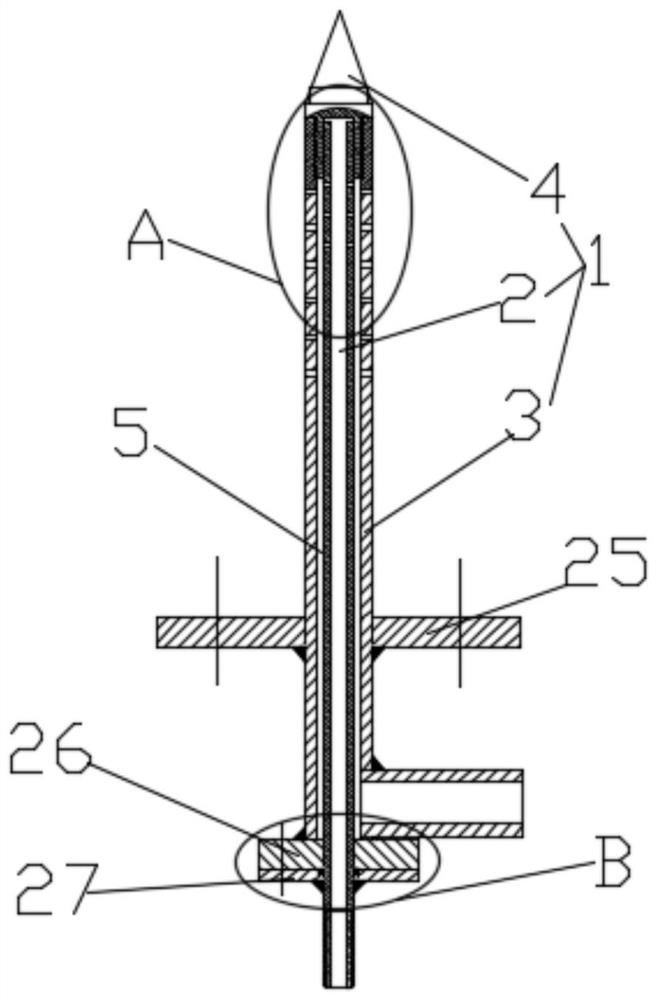

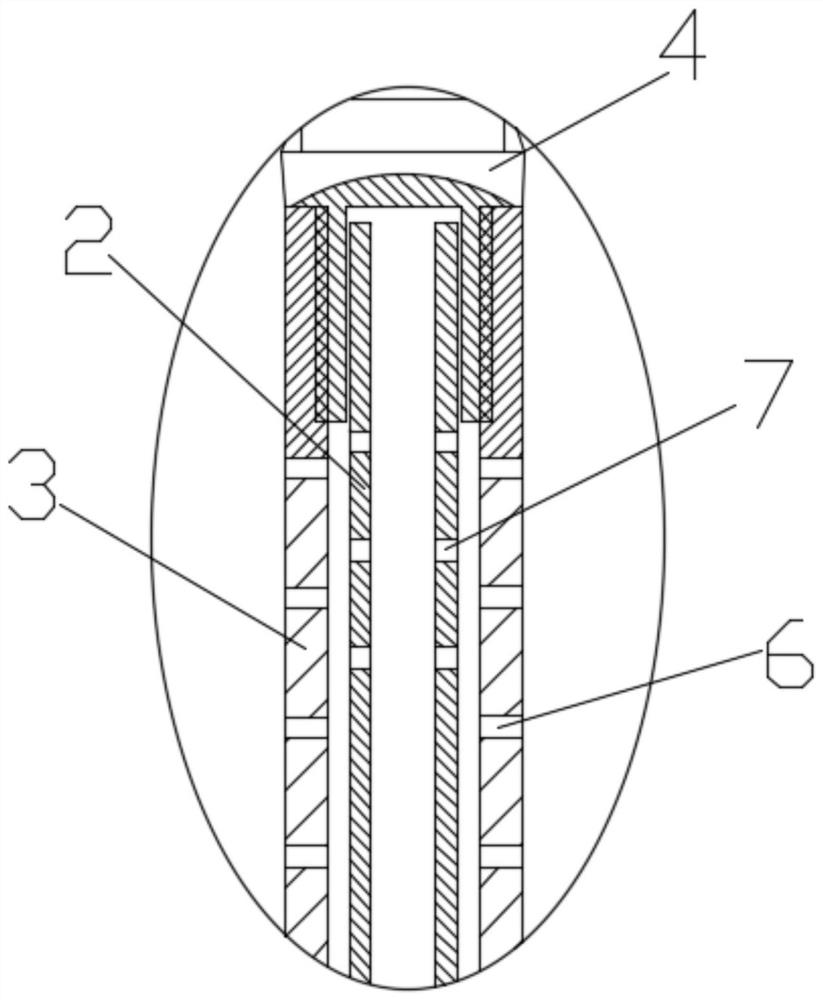

[0029] see Figure 1 to Figure 5 , a device for automatically taking coconut water provided by the present invention includes a water-taking needle 1 and a fixed pressure-applying device 8, the water-taking needle 1 is fixed on the fixed pressure-applying device 8, and the fixed pressure-applying device 8 is used for Fix the coconut 28, and press the coconut 28 to the tip of the water-taking needle 1, insert the water-taking needle 1 into the inner cavity of the coconut 28 to take water, and the end of the water-taking needle 1 away from the needle tip is connected with a pressure-reinforcing tube 15 and a storage tank. device 16.

[0030] In the traditional process of opening the coconut 28 to take water, the coconut 28 water is exposed to the air, causing ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap