Wire drawing device for high-strength and high-elongation copper-nickel fine wires

A high-strength, copper-nickel technology, used in metal extrusion cleaning equipment, metal extrusion, manufacturing tools, etc., can solve problems such as reducing the quality of copper-nickel fine wire finished products, protect copper-nickel fine wire, avoid residue, The effect of improving the quality of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

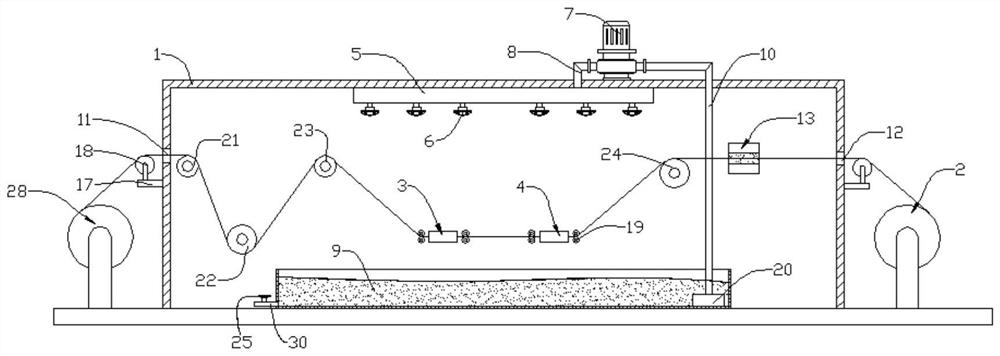

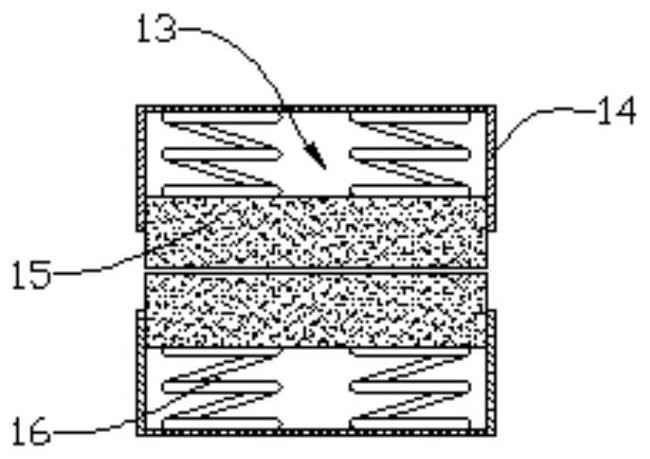

[0030] refer to figure 1 , figure 2 , image 3 , a wire drawing device for high-strength and high-stretch copper-nickel micro-wires, including a housing 1, a wire-releasing mechanism 28 and a wire-receiving mechanism 2 are installed and fixed on both sides of the housing 1, and the inner cavity of the housing 1 is provided with a first wire drawing The mechanism 3 and the second wire drawing mechanism 4, the top of the inner cavity of the housing 1 is fixedly connected with a water spray box 5, the bottom of the water spray box 5 is fixed with a plurality of nozzles 6, and the top of the housing 1 is fixed with a water pump 7, the water pump The water outlet of 7 is communicated with and fixed with a first connecting pipe 8, the end of the first connecting pipe 8 away from the water pump 7 extends to the inside of the housing 1 and communicates with the spray tank 5, and the bottom of the inner cavity of the housing 1 is fixedly connected with a water receiving tank 9 The w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap