Angle type duplex ball valve for nuclear submarine and using method thereof

A technology of double ball and nuclear submarine, applied in the direction of ships, valve devices, valve details, etc., can solve the problems of large ball valve structure, failure of device control, large space occupation, etc., to achieve strong bonding force, reduce leakage points, no casting The effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

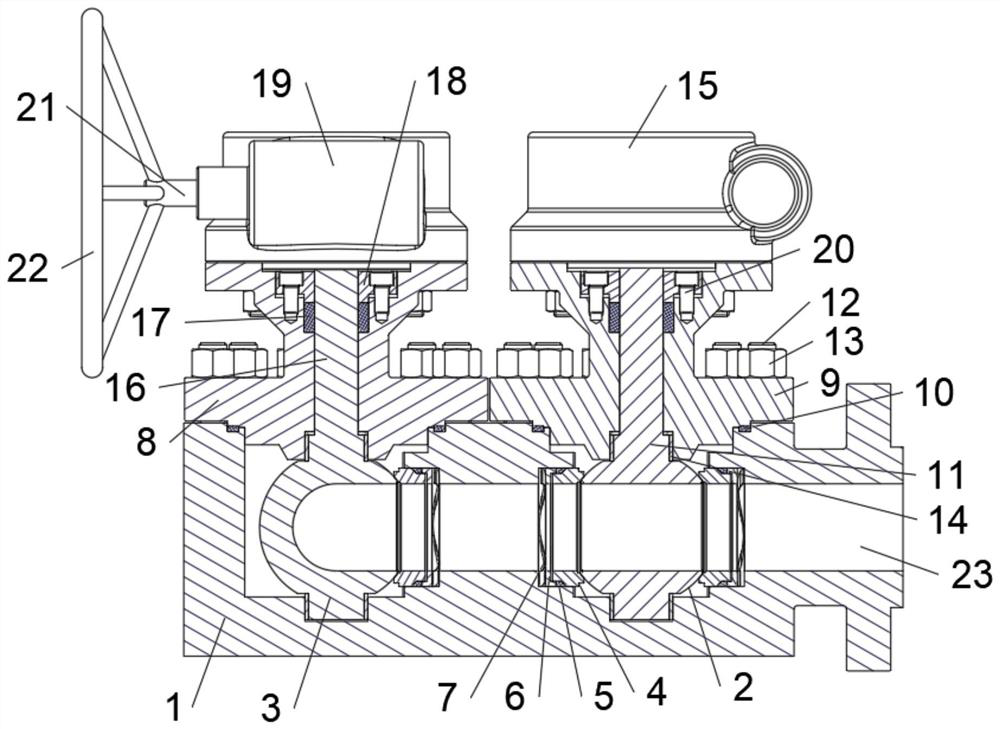

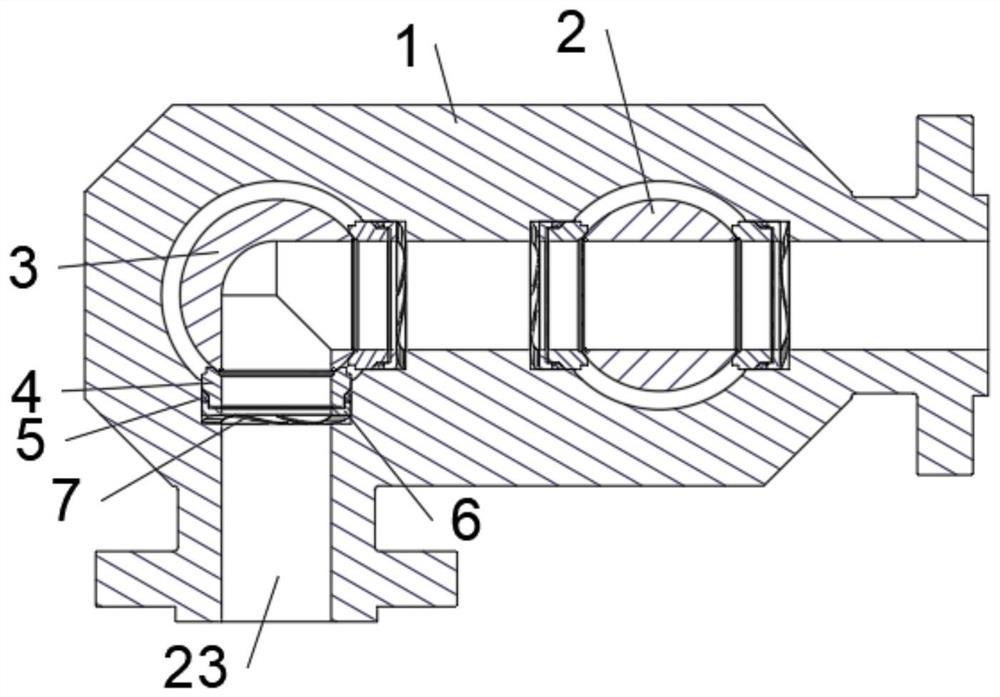

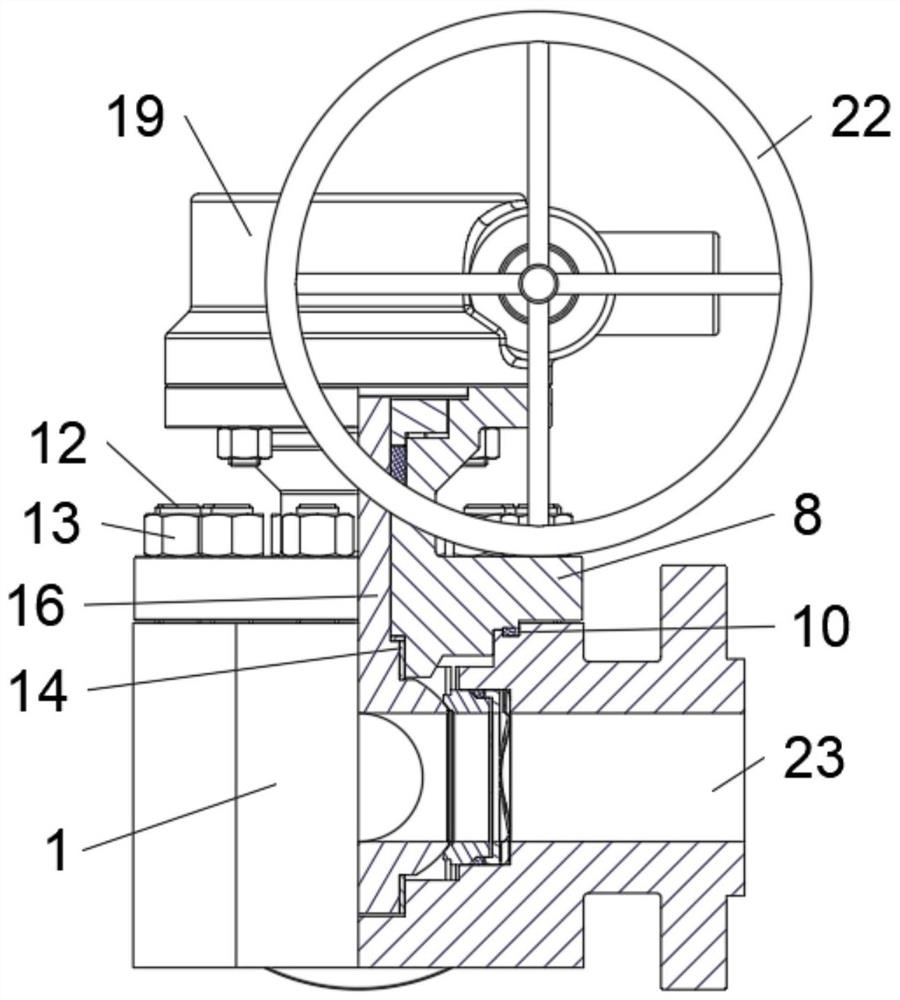

[0036] Such as Figure 1-Figure 5 As shown, the angle-type double-connected ball valve for nuclear submarines provided in this embodiment includes a valve body 1, and a pipeline 23 is fixed inside the valve body 1. The pipeline 23 is a right-angle bent pipeline, and the two ends of the pipeline 23 are respectively connected to the The two adjacent surfaces of the valve body 1 are connected, and a right-angled structure is adopted. In order to allow the valve to have a 90° turning function, the space size of the device and the number of accessories are minimized, and one part serves multiple functions, which can reduce the cost of one turn. Parts, reducing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com