Heat tracing pipe lossless replacement method, connection structure and device

A replacement method and connection structure technology, which is applied to heat exchange equipment, heat-insulated protection pipes, pipes/pipe joints/fittings, etc., can solve the problems of high cost, prevent falling off, improve tensile strength, and save manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical means, creative features, goals and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

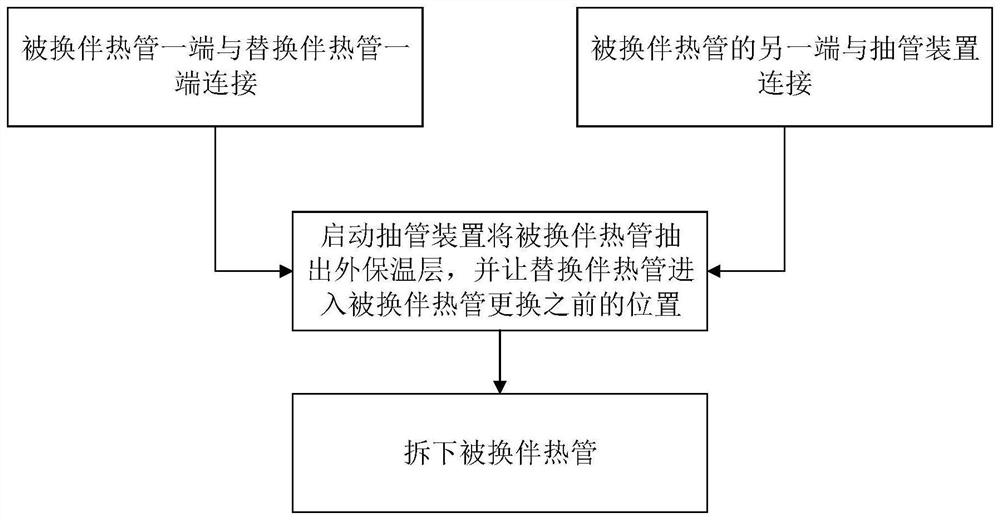

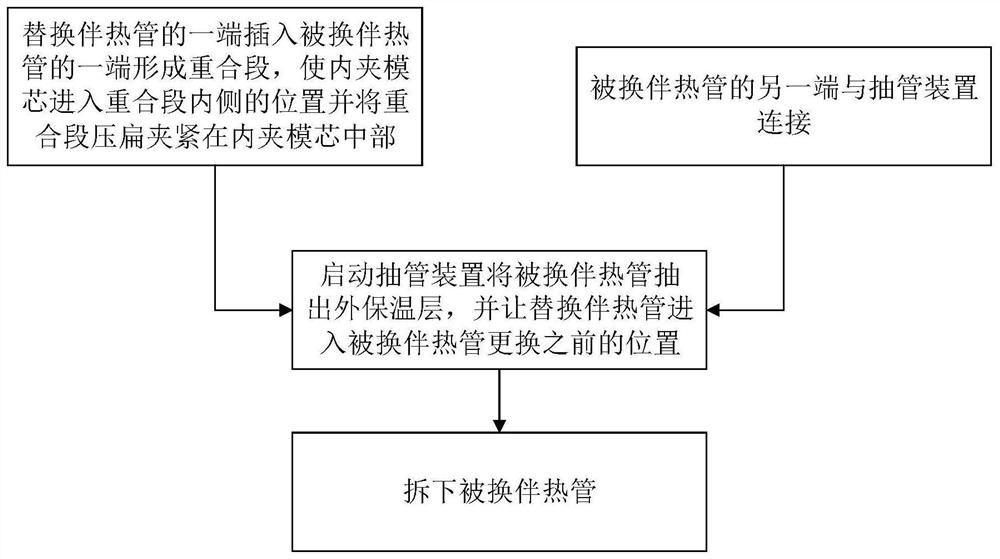

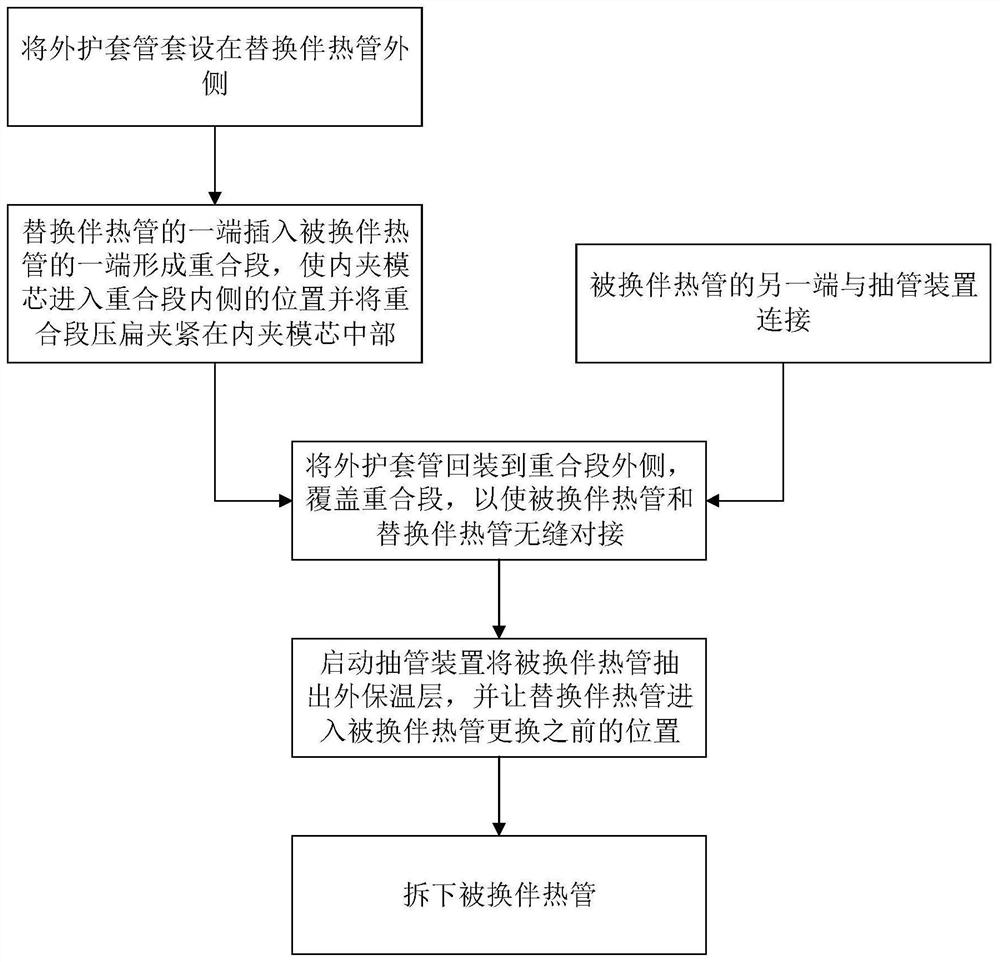

[0043] In the first aspect of the present invention, a method for non-destructive replacement of heat tracing pipes, such as figure 1 , 5 As shown, it includes a pipe extraction device 1, a replaced heat tracing pipe 4, and a replacement heat tracing pipe 5; the replaced heat tracing pipe 4 is arranged in parallel around the heated pipeline 3, and the heated pipeline 3 and the replaced heat tracing pipe The outside of 4 is surrounded by outer insulation layer 2; Also includes:

[0044] Connection step A: one end of the replaced heat tracing pipe 4 is connected to one end of the replacement heat tracing pipe 5;

[0045] Connection step B: the other end of the replaced heat tracing pipe 4 is connected to the pipe extraction device 1;

[0046] Extraction and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com