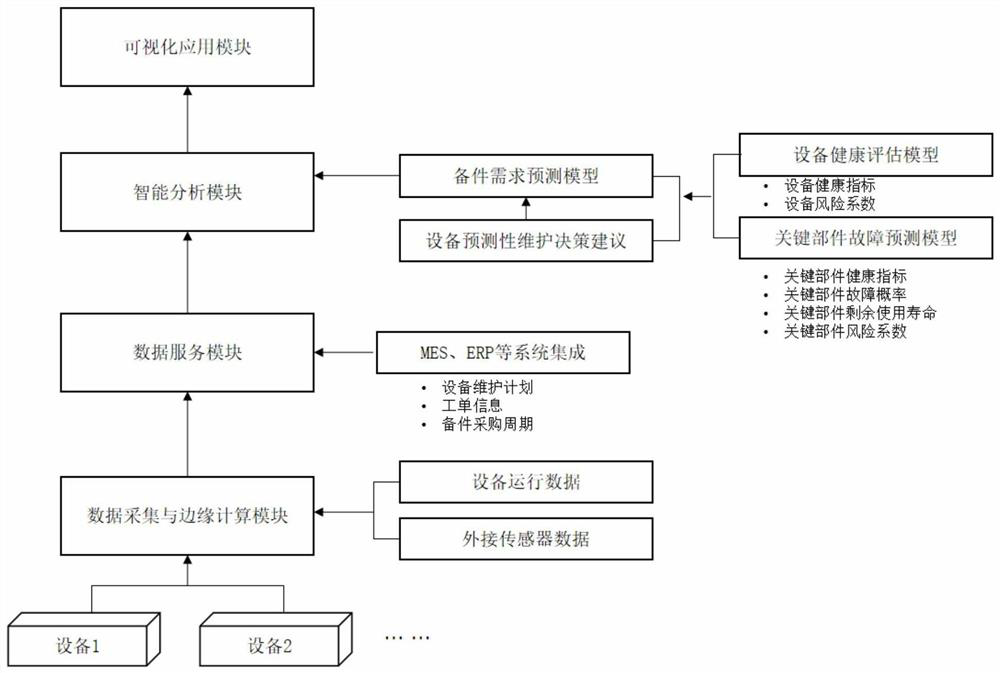

Equipment spare part demand prediction system based on fault prediction and health management

A demand forecasting and fault forecasting technology, applied in forecasting, manufacturing computing systems, data processing applications, etc., can solve problems such as difficult selection of trending features, feature mutations, etc., to reduce overall maintenance costs, easy implementation, and minimize inventory volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

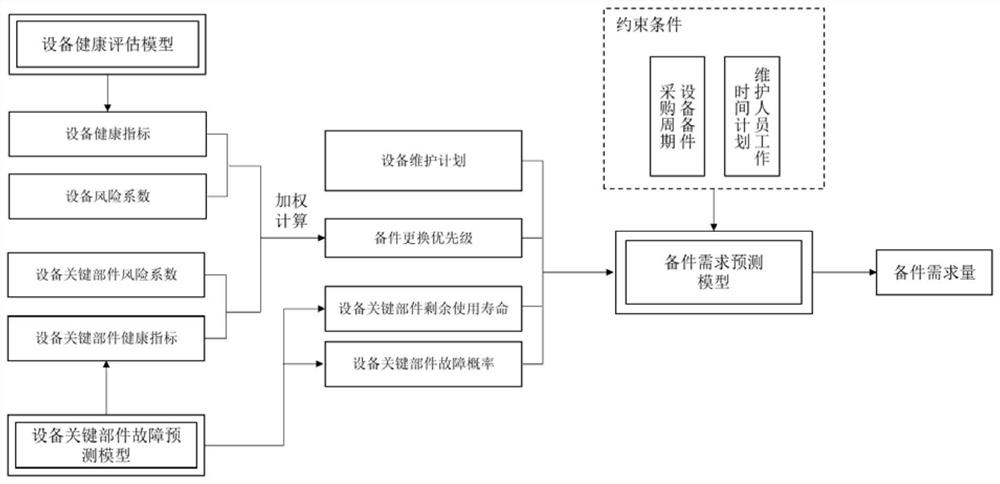

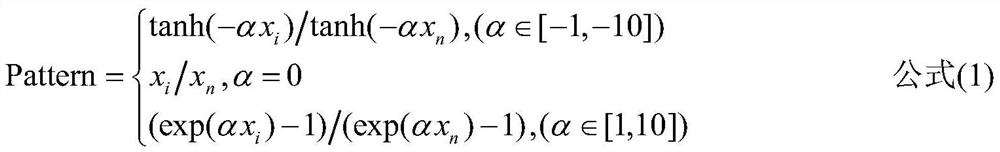

Method used

Image

Examples

Embodiment

[0091] In this embodiment, the equipment spare parts demand prediction system based on failure prediction and health management of the present application is used for the demand forecast of CNC machine tool spindle spare parts in the manufacturing plant. Spindle is the core component of CNC machine tools, and it is usually expensive. Once damaged, the cycle of repair, replacement or purchase will be long, which will cause long-term downtime of the machine tool and affect the production plan. Through the failure prediction and health management of the spindle, the abnormal condition of the spindle can be detected in time, the spare parts demand of the spindle can be accurately predicted, the inventory can be reasonably optimized or the purchase can be arranged in advance, and long-term machine downtime can be avoided. The specific implementation process is as follows:

[0092] Data Acquisition and Edge Computing Module

[0093] Set the machine tool spindle variable speed no-lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com