Heat dissipation device used in cooperation with power transformer

A technology for power transformers and heat dissipation devices, applied in the direction of transformer/inductor cooling, etc., can solve problems such as poor practicability and inability to achieve technological breakthrough innovations, and achieve the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

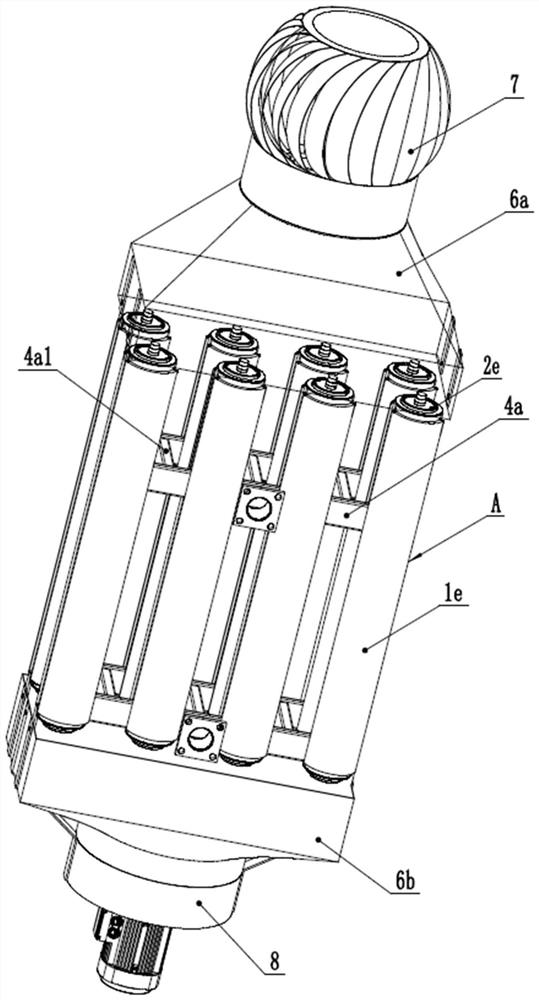

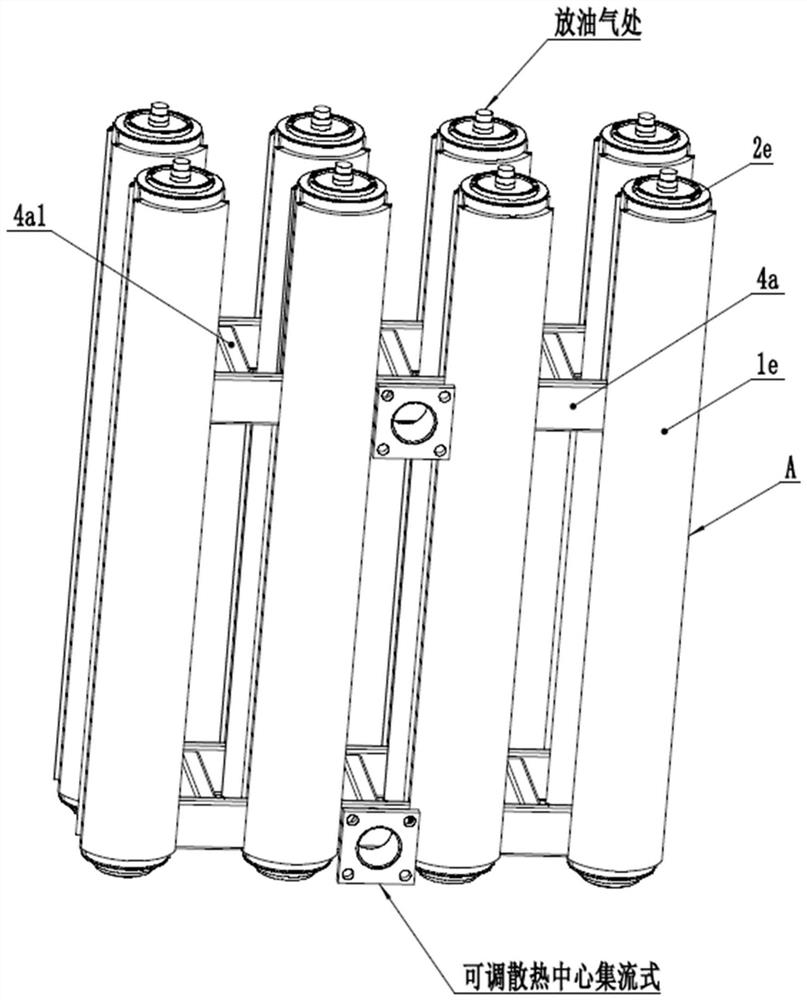

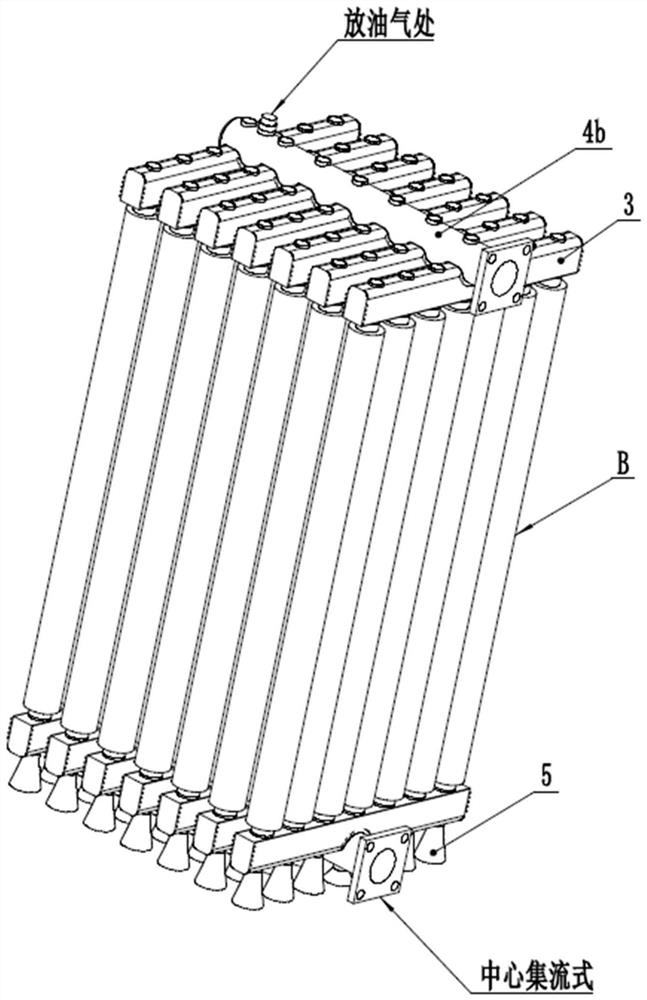

[0048] The heat dissipation device used in conjunction with this power transformer includes a heat dissipation unit, a heat dissipation unit, a heat dissipation assembly, a ventilation component, and a PLC fan control unit. The heat dissipation assembly is made of aluminum alloy, copper, and steel, and the heat dissipation medium includes transformer oil. , Sulfur hexafluoride gas, the inlet and outlet flanges are connected to the heat dissipation medium pipeline of the transformer, which is characterized in that the inner pipe and the outer pipe are set together to form a multi-layer cavity A type, B type heat dissipation unit, and the junction box 3 is composed The heat dissipation unit, the heat dissipation unit and the three kinds of collectors 4b~4d form a heat dissipation assembly, which constitutes a central collection type and a peripheral collection type heat dissipation assembly. The difference is that the adjustable heat dissipation center type heat dissipation The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com