Electron-phonon coupled high-integration all-solid-state laser wavelength regulation and control method and laser

A laser wavelength and highly integrated technology, applied in the laser field, can solve problems such as the inability to achieve laser wavelength, precise regulation and stable output, etc., and achieve the effects of easy mass production, ensuring consistency, and reducing production debugging and processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0050] Example 1:

[0051] A highly integrated all solid state laser control device that realizes electron phonon coupling with 850nm output.

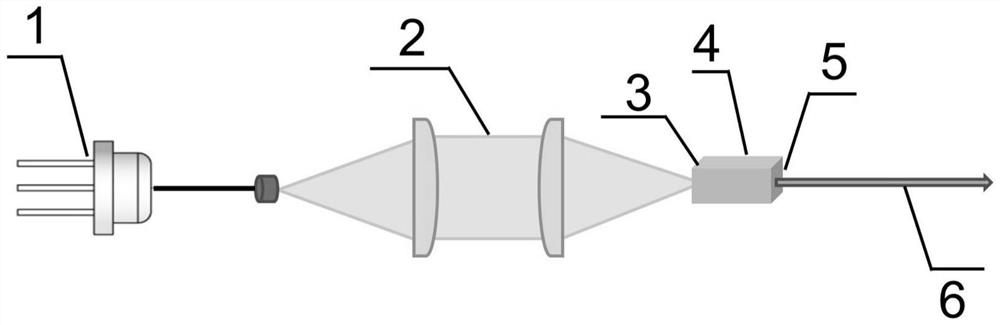

[0052] Structure such as Figure 1 As shown in the figure, the pump source 1, the laser focusing system 2 and the electron phonon coupling laser crystal 4 arranged in sequence along the optical path direction; Wherein, the pump source 1 is a laser diode laser, the pump wavelength is 658nm, and the electron phonon coupling laser crystal 4 is an emerald crystal, CR 3+ The ion doping concentration is 0.2at.% (at.% is the atomic percentage), the cutting direction, i.e. the light passing direction is the Z direction of the optical axis, the light passing length of electron phonon coupled laser crystal 4 is 10mm, the distance between the section center and the heat dissipation surface is 1.5mm, and the crystal temperature is controlled to 50 ℃.

[0053] An input cavity mirror dielectric film 3 is plated on the incident light end of the electron p...

Example Embodiment

[0055] Example 2:

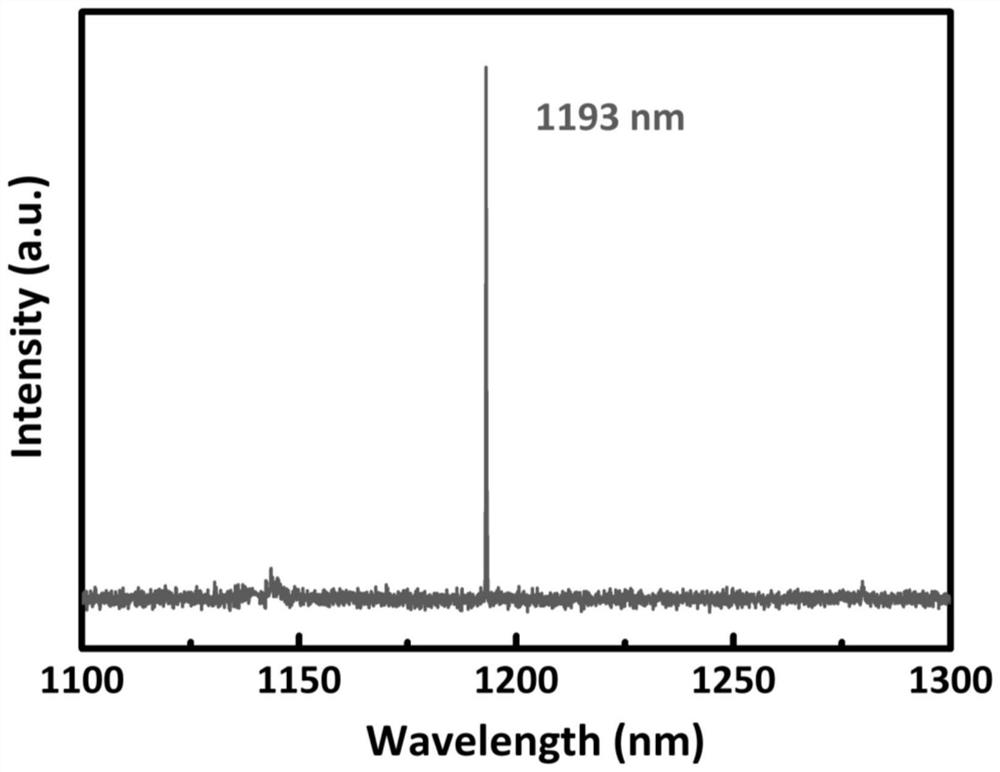

[0056] As described in example 1, the difference is that the emission wavelength of pump source 1 is 976 nm, and the electron phonon coupling laser crystal is Yb 3+ Doped calcium borate yttrium oxide crystal, Yb 3+ The ion doping concentration is 20at.%. The crystal length is 6mm and the temperature is controlled at 5 ℃. The input cavity mirror dielectric film 3 is plated with a dielectric film with high transmittance of 900-1000 nm, high reflection of 1180-1200 nm and 70% transmittance of 1140-1160 nm; The output cavity mirror dielectric film 5 has a high reflection of 900-1000nm, a transmittance of 10% to 1180-1200nm and a transmittance of 70% to 1220-1240nm. Through the Huang Kun factor gain calculation, the maximum gain direction of electron phonon coupling of 1193nm laser wavelength emitted by the crystal is in the z-axis (103 ° ± 1 °) and X-axis (27 ° ± 1 °), and the focusing system is in the focusing ratio of 2:1. Increase the pump power to realize the e...

Example Embodiment

[0057] Example 3:

[0058] As described in example 1, the difference is that the pump source 1 is an all solid state laser, the emission wavelength is 532nm, and the electron phonon coupling crystal is titanium gem, Ti 3+The ion doping concentration is 0.1at.%, The crystal temperature is controlled at 10 ℃. The input cavity mirror dielectric film 3 is plated with a dielectric film with high transmission to 500-550 nm, high reflection to 880-920 nm and high transmission to 750-850 nm; The output cavity mirror dielectric film 5 is plated with a dielectric film with high reflection to 500-550 nm, 5% transmittance to 880-920 nm and 940-980 nm. The crystal is a trilateral system, and the imaginary part of its refractive index coincides with the real part. The crystal is cut along the z-axis direction of the optical axis, that is, the light passing direction is along the z-axis. The electron phonon coupling laser output with a wavelength of 900 nm is realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap