Fabrication process of high-brightness LED

A preparation process and high-brightness technology, applied in the field of lighting, can solve the problems of commercial production, high preparation cost, complicated process, etc., and achieve reduced production cost and process complexity, easy controllable wavelength, and indium component content stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

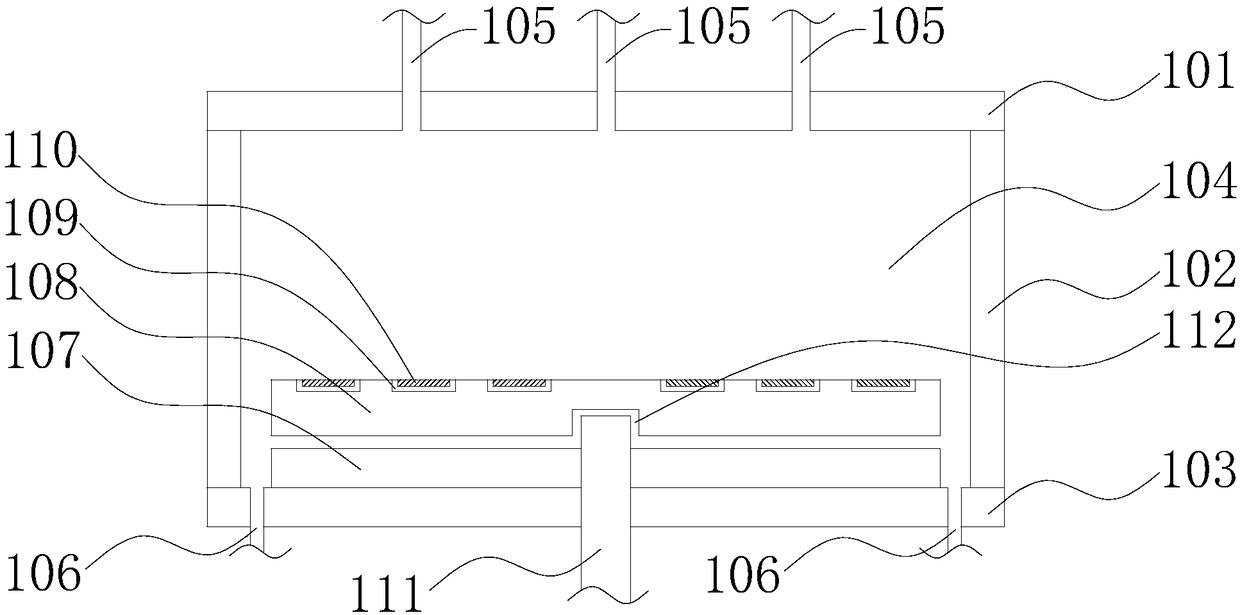

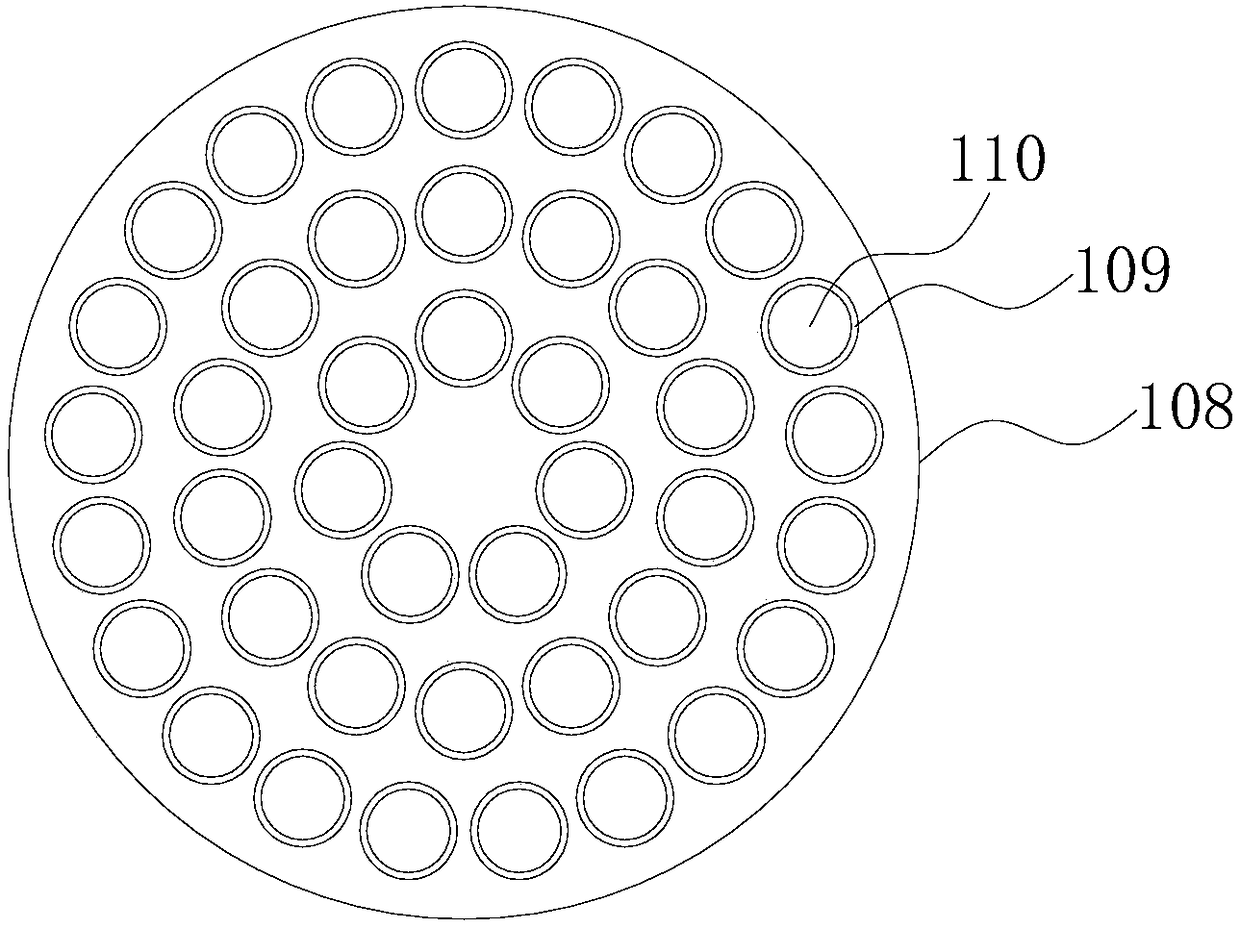

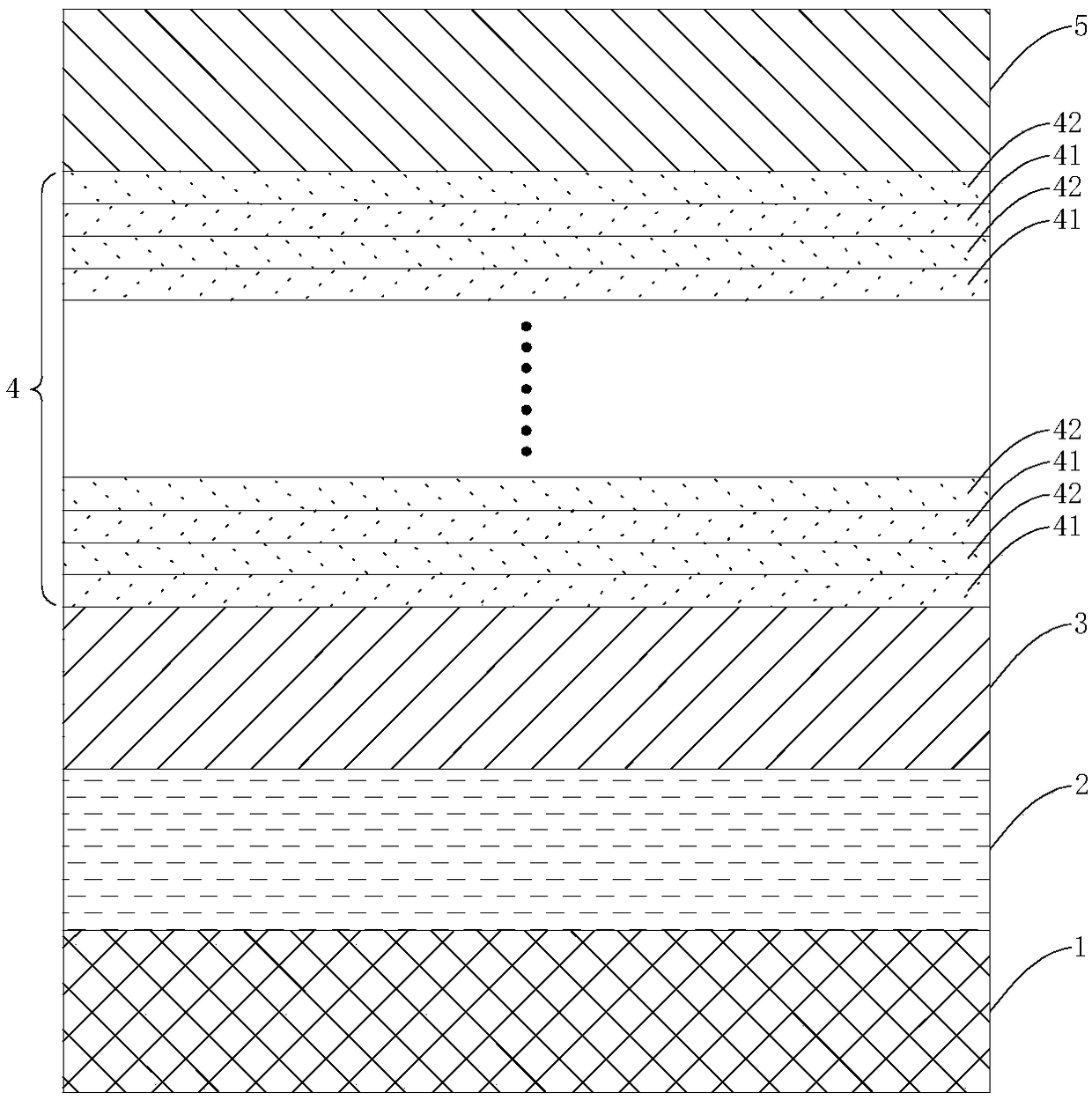

[0029] Please refer to figure 1 , figure 2 , when manufacturing LEDs by MOCVD (Metal Organic Chemical Vapor Deposition, Metal Organic Chemical Vapor Deposition) equipment, the substrate 110 is first placed in the grooves 109 evenly distributed on the carrier plate 108, and the depth of the grooves 109 is slightly higher than that of the substrate. The thickness of the bottom 110, the size of the substrate 110 can be two inches, four inches or six inches, and the slide disc 108 is made of high temperature resistant material, such as graphite. Then transfer the slide tray 108 with the substrate 110 into the reaction chamber 104. The reaction chamber 104 is a closed structure formed by the upper cover 101, the side wall 102 and the base 103. Trachea 105, reaction gas, carrier gas (NH3, N2, H2, etc.) and MO source (trimethylgallium, triethylgallium, trimethylaluminum, trimethylindium, dimagnesium, etc.) The reaction in the reaction chamber 104 is then deposited on the substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com