Multi-point optical fiber mash gas sensing system based on optical fiber caching machine

A sensing system and optical fiber sensing technology, applied in the field of multi-point gas sensing system, can solve the problems of impossible practical application, technical infeasibility, bulky and so on, so as to improve the control signal and time synchronization performance, improve the Flexibility and accuracy, the effect of reducing optical path transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

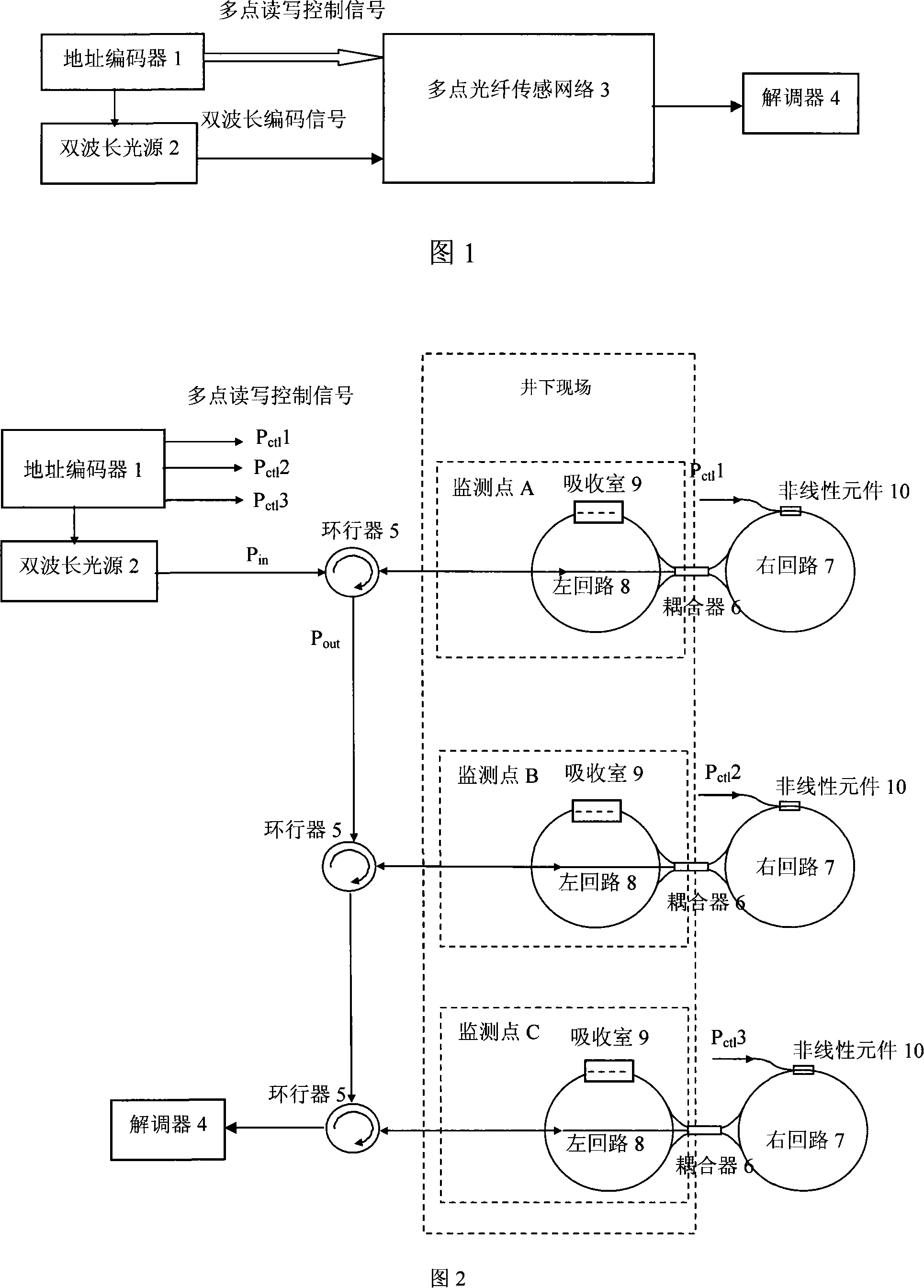

[0032] Embodiment 1: A multi-point optical fiber gas sensor system using a dual-ring coupled all-optical buffer;

[0033] As shown in Figure 1, the multi-point optical fiber gas sensor system based on dual-ring coupled all-optical buffers consists of an address encoder 1, a dual-wavelength light source 2, and a multi-point optical fiber transmission system composed of multiple dual-ring coupled all-optical buffers. Sense network 3, and a demodulator 4. The multi-point optical fiber sensor network 3 is shown in Figure 2, and it is made up of multiple double-ring coupled all-optical buffers, and each double-ring coupled all-optical buffer includes a circulator 5, a 3X3 coupler 6 arranged in parallel, left and right two An optical fiber loop 7 and 8, an absorption chamber 9 and a nonlinear element 10.

[0034] The address encoder 1 sets different patterns for different monitoring points, modulates the 1665nm dual-wavelength light source 2 in Figure 2, and generates control signa...

Embodiment 2

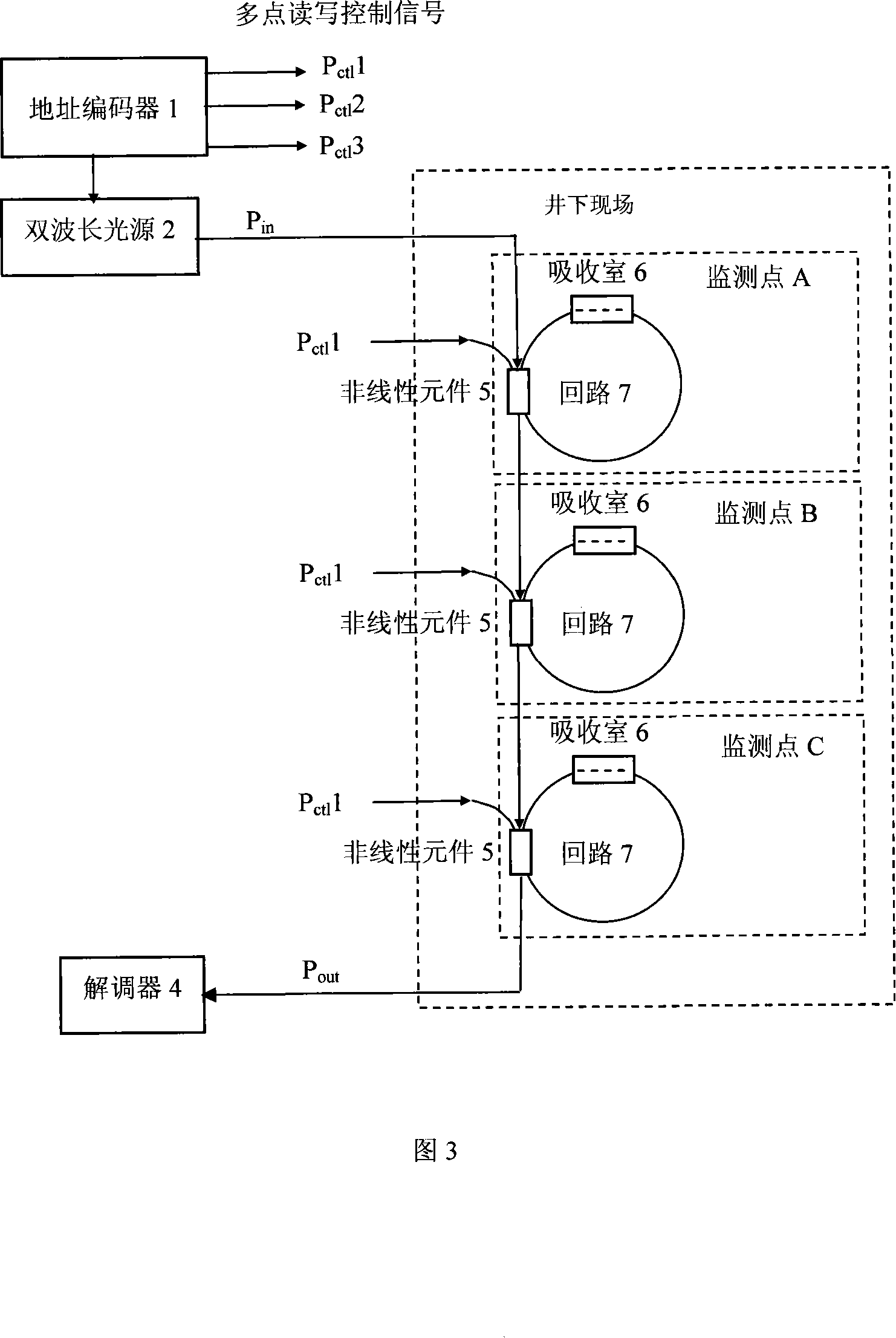

[0037] Embodiment 2: A multi-point optical fiber gas sensor system using a polarization-type all-optical buffer;

[0038] As shown in Figure 1, the multi-point optical fiber gas sensor system based on dual-ring coupled all-optical buffers consists of an address encoder 1, a dual-wavelength light source 2, and a multi-point optical fiber transmission system composed of multiple polarization-type all-optical buffers. Sense network 3, and a demodulator 4. The multi-point optical fiber sensing network 3 is shown in Figure 3, each monitoring point uses a polarization type all-optical buffer, and a gas absorption chamber 6 is placed in the optical fiber loop of the buffer. Therefore, each polarization-type all-optical buffer includes a nonlinear element 5 , an absorption chamber 6 , and a section of optical fiber loop 7 . The optical fiber loop 7 referred to here includes a section of optical fiber and accessories to improve loop performance, such as polarization controllers, ampli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com