Method for testing and evaluating PID performance of battery assembly

A battery component and performance technology, applied in the field of testing and evaluating the PID performance of battery components, can solve the problems of long test cycle and high test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

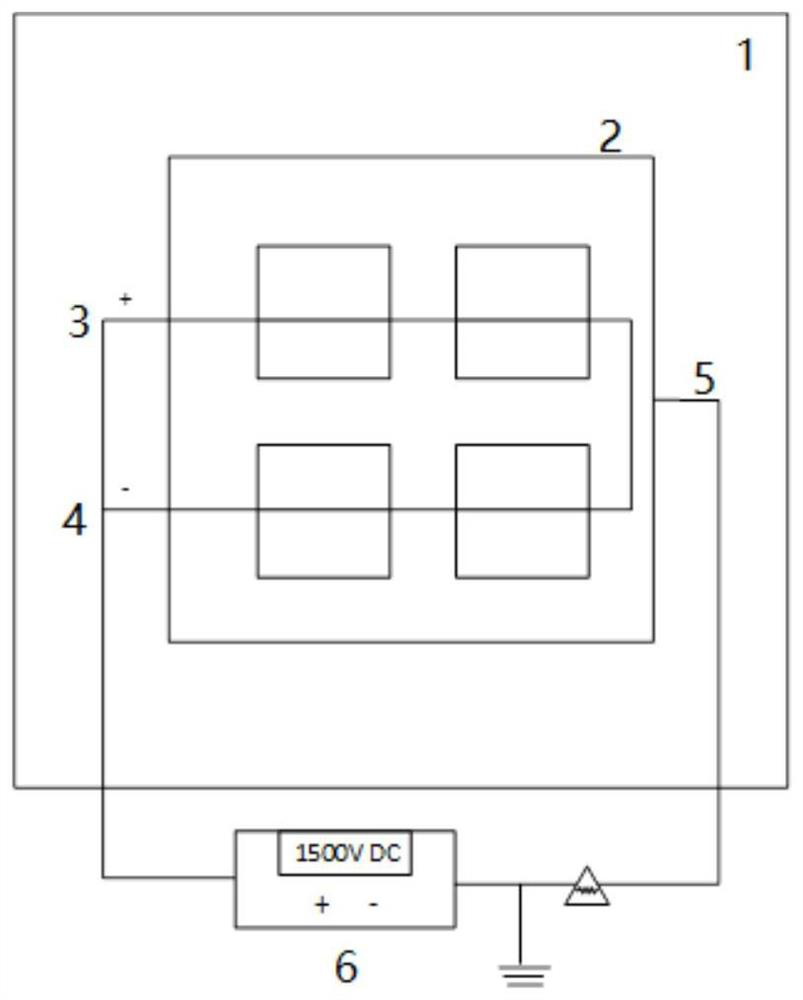

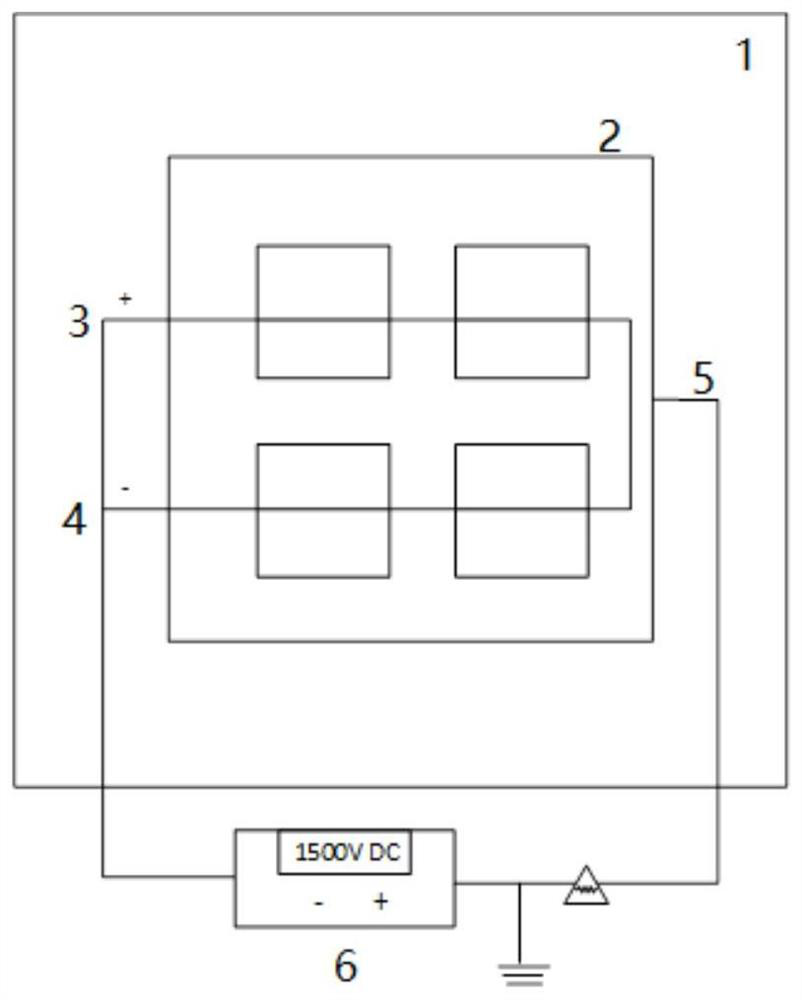

[0023] Such as figure 1 with figure 2 Shown, the method for testing and assessing battery assembly PID performance of the present invention, it comprises the steps:

[0024] (1) A constant voltage source 6 is externally connected to the environmental test chamber 1 to provide voltage, and a ground wire is drawn from the ground terminal to be grounded to the edge of the laminate 2;

[0025] (2) The laminate 2 is wrapped with aluminum foil and placed in an environmental test box, and the lead-out lines 3 and 4 of the laminate are connected to the joints of the constant voltage source 6;

[0026] (3) Connect the short-circuited joint of the laminate to the interface of the constant pressure source. The environmental test chamber operates under high temperature and high humidity conditions (85°C / 85% RH). The laminate is wrapped with aluminum foil, and the layer is given A certain voltage is applied to the pressing piece, and it runs n×96h.

[0027] In this embodiment, the cons...

specific example

[0033] Specific example: Randomly select 2pcs of cells with 23.2% of the mainstream gear of the production line TOPCon and use 0.35mm solder ribbon to realize welding at 175°C, and use glass / POE / battery / POE / glass packaging lamination to complete the preparation of laminates , the system voltage selection is -1500V, the temperature of the environmental test chamber is set to 85°C, and the humidity is set to 85%RH. The laminated parts are wrapped with aluminum foil to complete the circuit connection. After the conditions are stable, the test is performed for 192 hours. Record and compare changes.

[0034] The method for testing and evaluating the PID performance of the battery assembly of the present invention is easy to implement and relatively low in testing cost, but it can effectively evaluate the anti-PID performance of the finished battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com