Rubber shoe edge pressing processing equipment and using method thereof

A processing equipment and edge pressing technology, applied in footwear, application, bonding shoe parts, etc., can solve the problems of poor processing effect, raised waste cutting, damage to rubber shoe soles, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

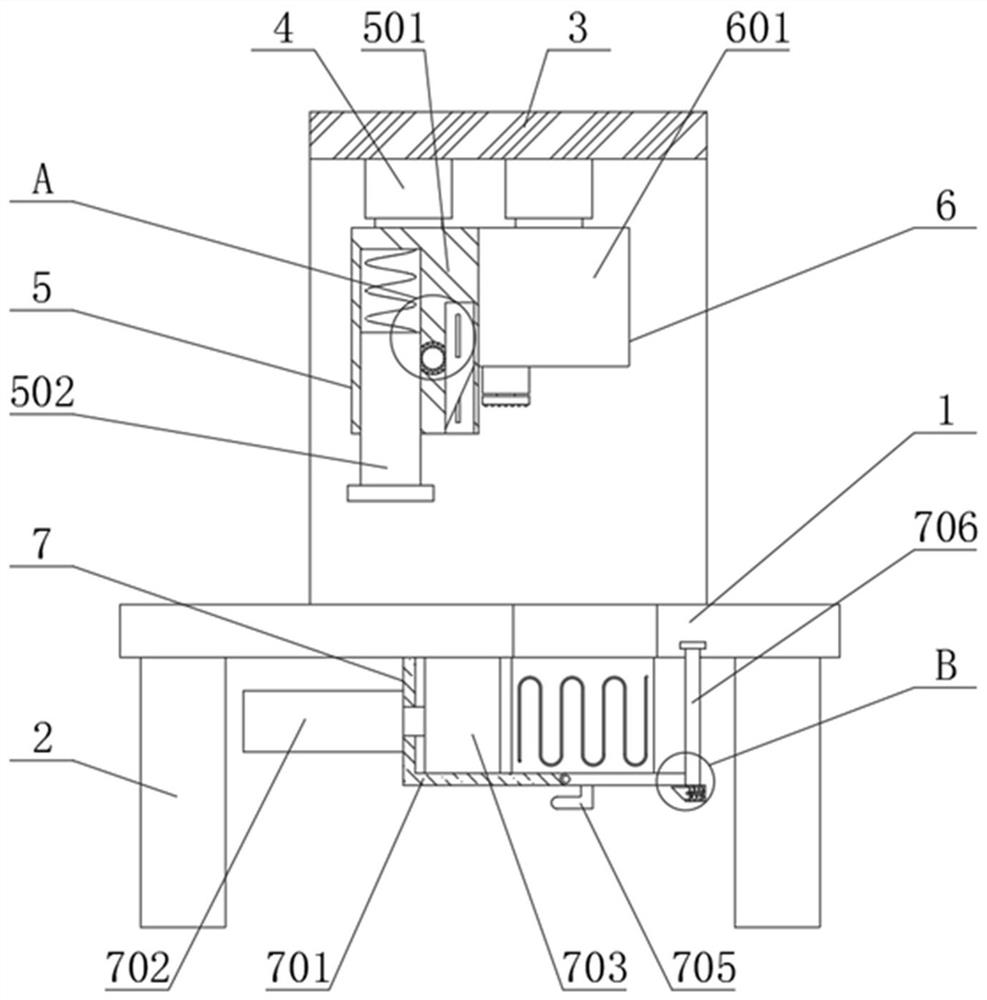

[0028] see Figure 1-5 , the present invention provides a technical solution:

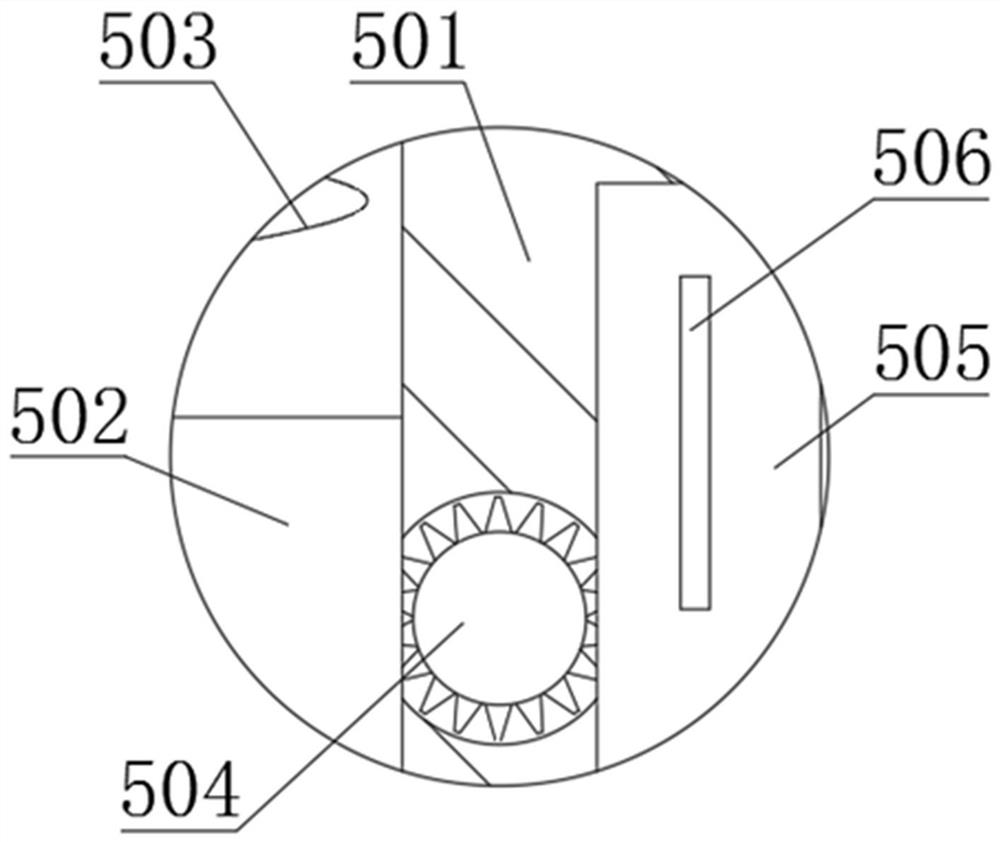

[0029] A rubber shoe hemming processing device and its use method, comprising a hemming processing table 1 and a hemming cutting mechanism 5, the bottom end of the hemming processing table 1 is fixedly connected with a support column 2, and the top end of the hemming processing table 1 is fixedly connected with a Top frame 3, the top of the top frame 3 is fixedly connected with a hydraulic telescopic rod 4, and the hydraulic telescopic rod 4 is symmetrically arranged on the inner top of the top frame 3, and the bottom end of the hydraulic telescopic rod 4 on the left side is fixedly connected with an edge cutting mechanism 5. This setting can drive the edge cutting mechanism 5 to move downward through the hydraulic telescopic rod 4 located on the left side. The edge cutting mechanism 5 includes a first lifting seat 501, a edge block 502, a buffer spring 503, a transmission gear 504, Slitting cutte...

Embodiment 2

[0033] see Figure 1-5 , the present invention provides a technical solution:

[0034] A rubber shoe hemming processing device and its use method, the same parts in embodiment 2 as in embodiment 1 will not be repeated in the present invention, and the difference lies in the working process.

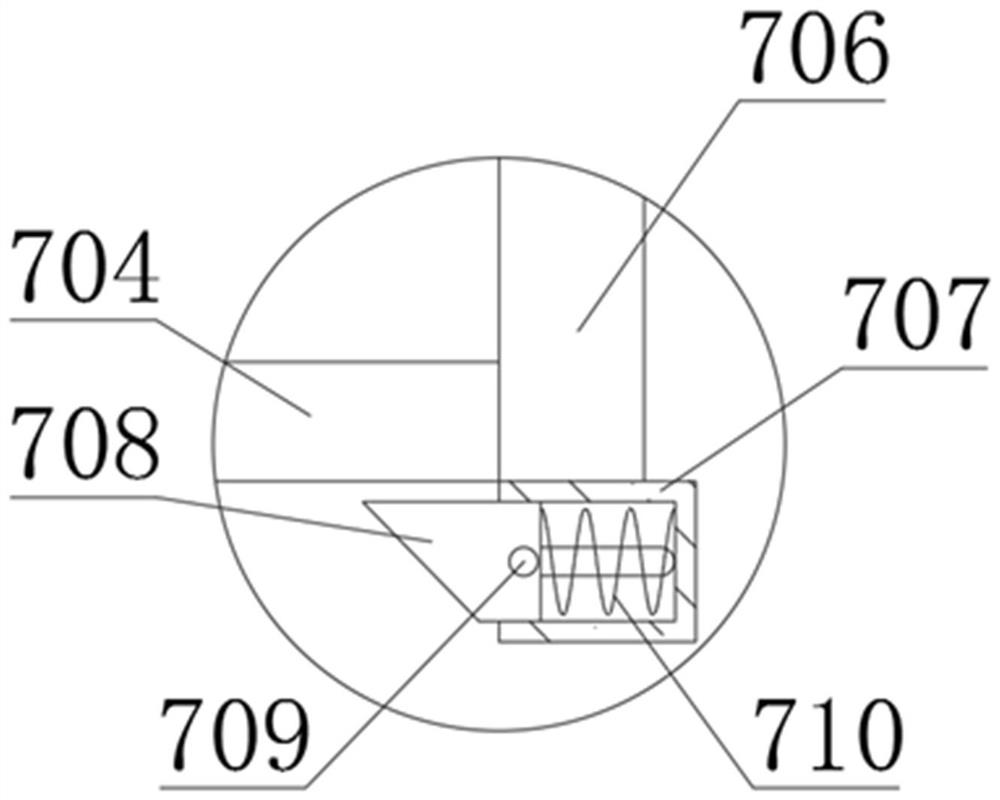

[0035] Workflow: When the cut side material does not need to be compressed, first slide the slide plate 706 forward so that the slide plate 706 is no longer located at the right end of the heat treatment box 701, and after the slide plate 706 slides, the limit protrusion 708 The rotating plate 704 is no longer limited, and the rotating plate 704 is rotated under the action of gravity until the limit rubber part 705 contacts the bottom of the heat treatment box 701 to realize the buffering of the rotating plate 704. At this time, the rotating plate 704 is In the inclined state, at this time, after the side material dropped in the heat treatment box 701 is heated and softened, the push blo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap