Novel constructional engineering sand screening device

A technology for construction engineering and sand screening, applied in the field of new construction engineering sand screening devices, can solve the problems of increased worker burden, low screening efficiency, inconvenient use, etc., and achieves the effects of reducing screening time, lightening work burden, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

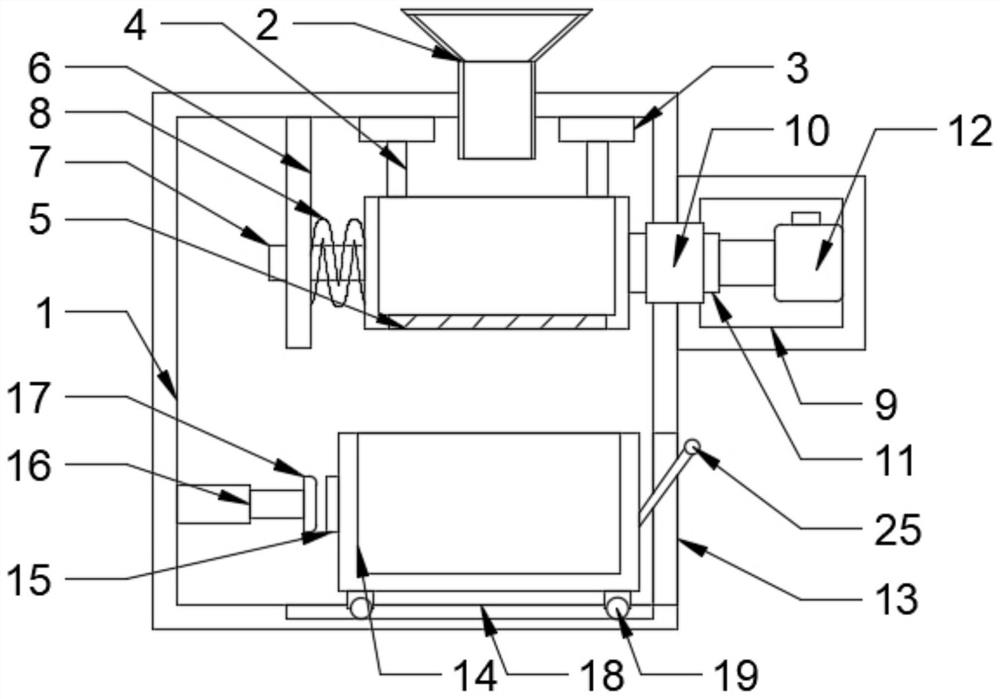

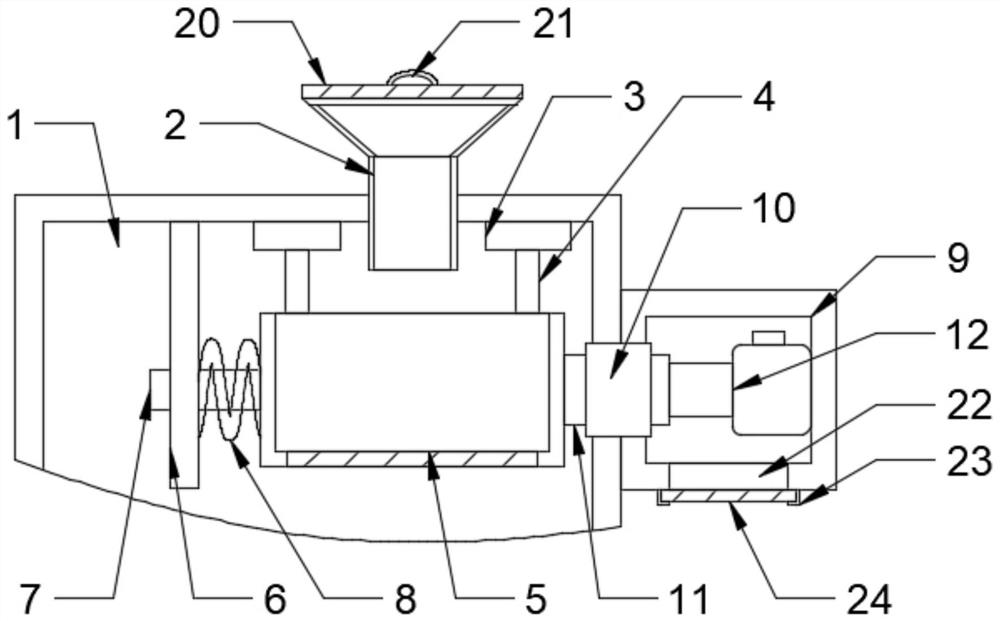

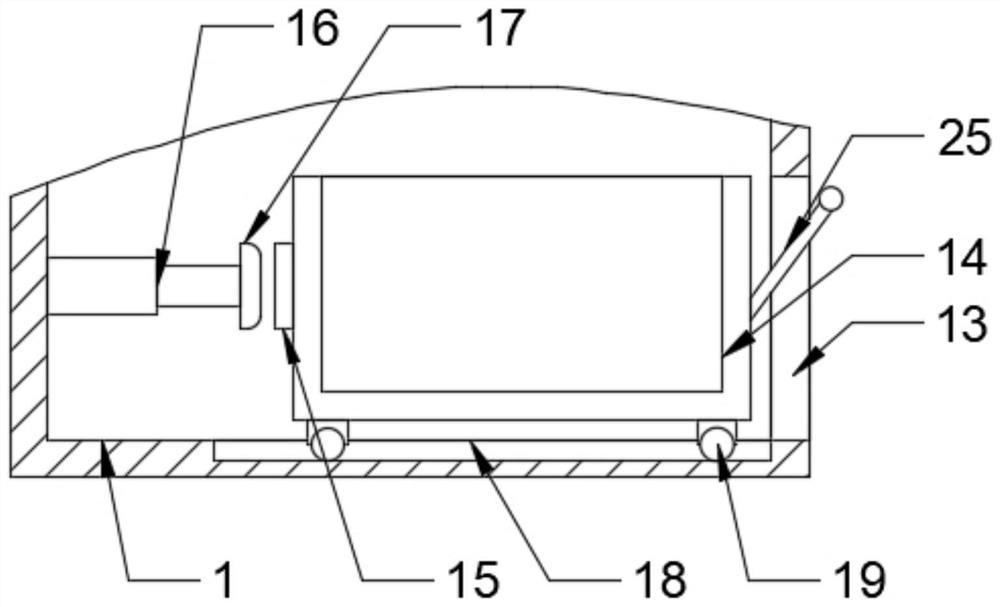

[0021] Embodiment: when in use, start the hydraulic cylinder 12, the telescopic end of the hydraulic cylinder 12 stretches back and forth, the telescopic end of the hydraulic cylinder 12 drives the connecting sleeve rod 11 to slide in the fixed sleeve 10, and the connecting sleeve rod 11 drives the screening frame 5 to shake left and right , when the screening frame 5 moves, it drives the connecting slide bar 4 to slide on the fixed slide rail 3, and the screening frame 5 drives the connecting rod 7 to slide on the fixed plate 6, and the screening frame 5 exerts pressure on the telescopic spring 8, and the telescopic spring 8 is deformed. The telescopic spring 8 exerts a reset force on the screening frame 5, the user turns over the movable cover 20 through the fixed handle 21 to open the feeding hopper 2, pours the sand into the feeding hopper 2, and the sand falls to the screening frame through the feeding hopper 2 5, the sand is screened by shaking the screening frame 5 left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com