Automatic equipment and method with waste recovery function and used for metal material manufacturing

A technology of automation equipment and metal materials, applied in metal processing equipment, other manufacturing equipment/tools, metal processing, etc., can solve problems such as potential safety hazards, easy scratches, waste of time, etc., to improve accuracy and facilitate recycling and handling , the effect of maintaining cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

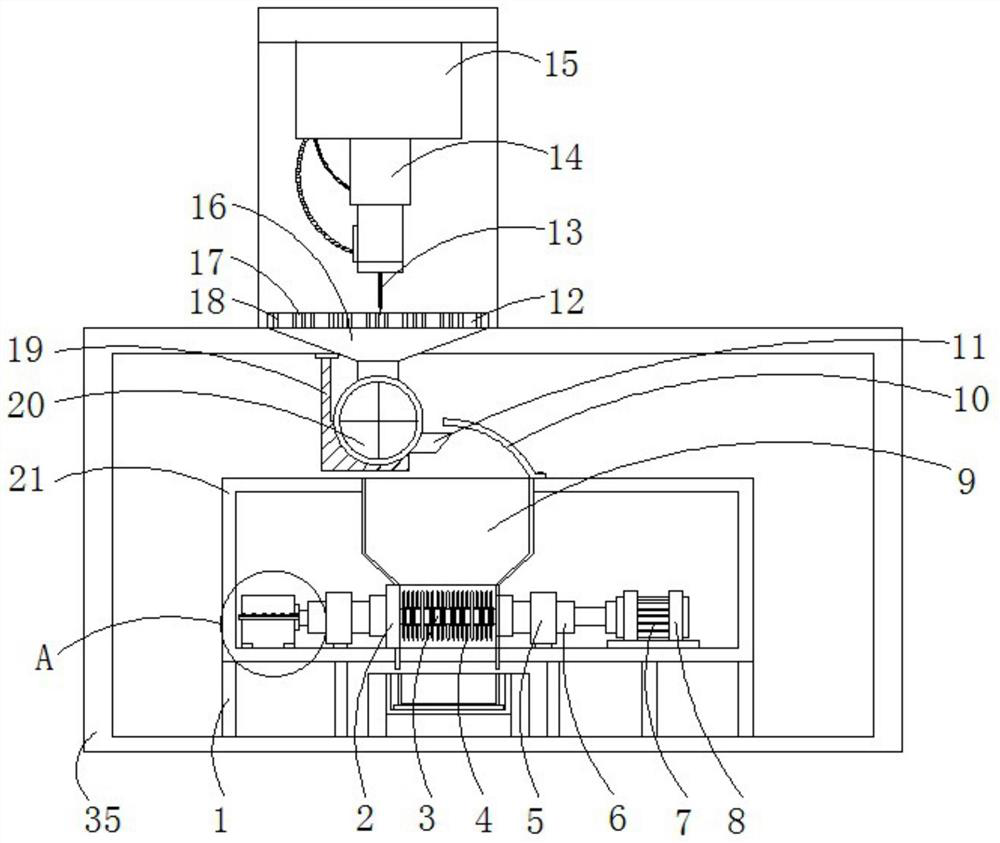

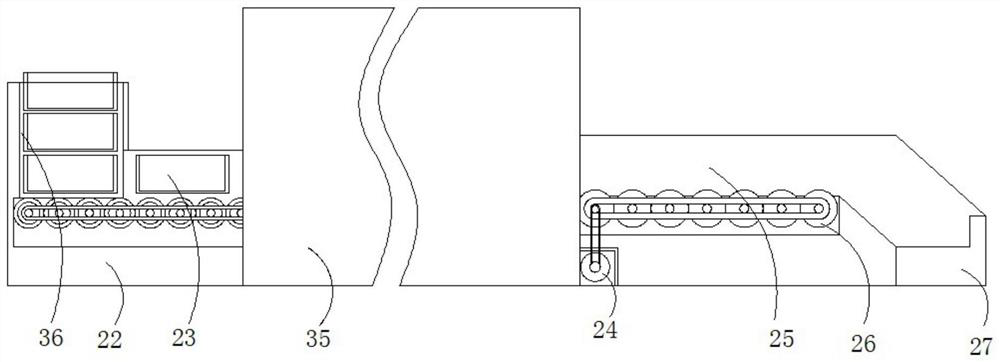

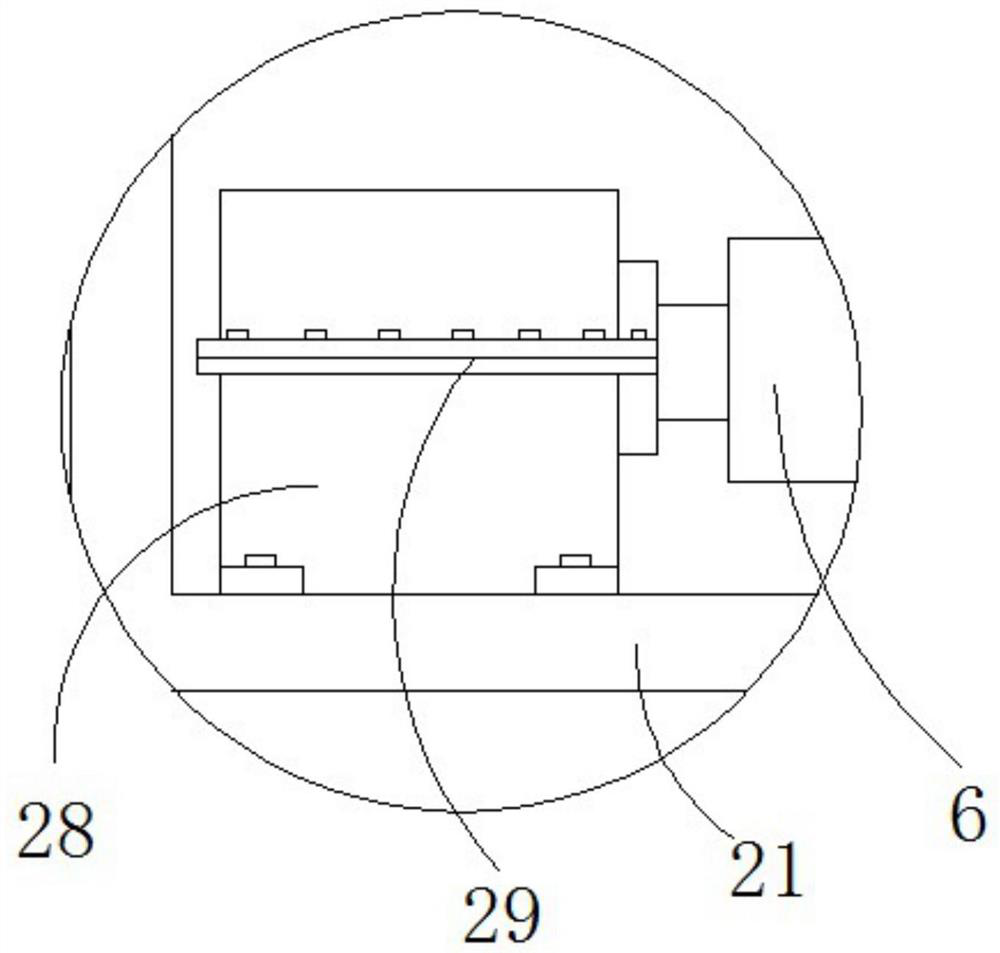

[0034] Please refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 ,in figure 1 A schematic diagram of the overall internal structure provided by the present invention, figure 2 It is a schematic diagram of the external structure of the transmission device provided by the present invention, image 3 for figure 1 Partial enlarged view of A in the middle, Figure 4 The structure diagram of the external fixed ring provided by the present invention, Figure 5 It is a schematic diagram of the structure of the external fixing ring provided by the present invention. An automated equipment for metal material manufacturing with waste recycling, including a workbench 35;

[0035] A plurality of support legs 1 , and the bottoms of the plurality of support legs 1 are all fixedly connected to the top of the inner wall of the workbench 35 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com