Mandrel for static pressure cylindrical grinding machine for machining thin-wall long shaft parts

A cylindrical grinding machine, long axis technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools and other directions, can solve difficult processing and other problems, to achieve the effect of rapid clamping and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

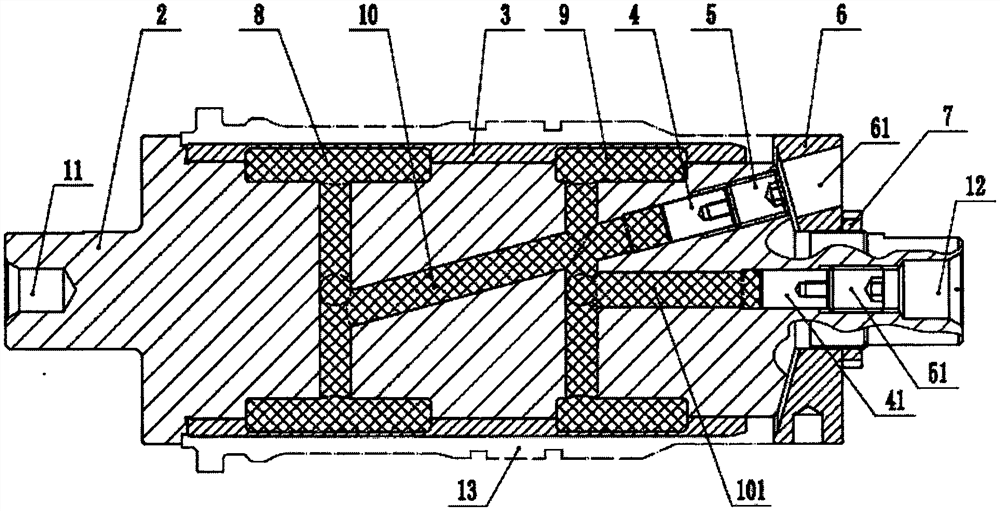

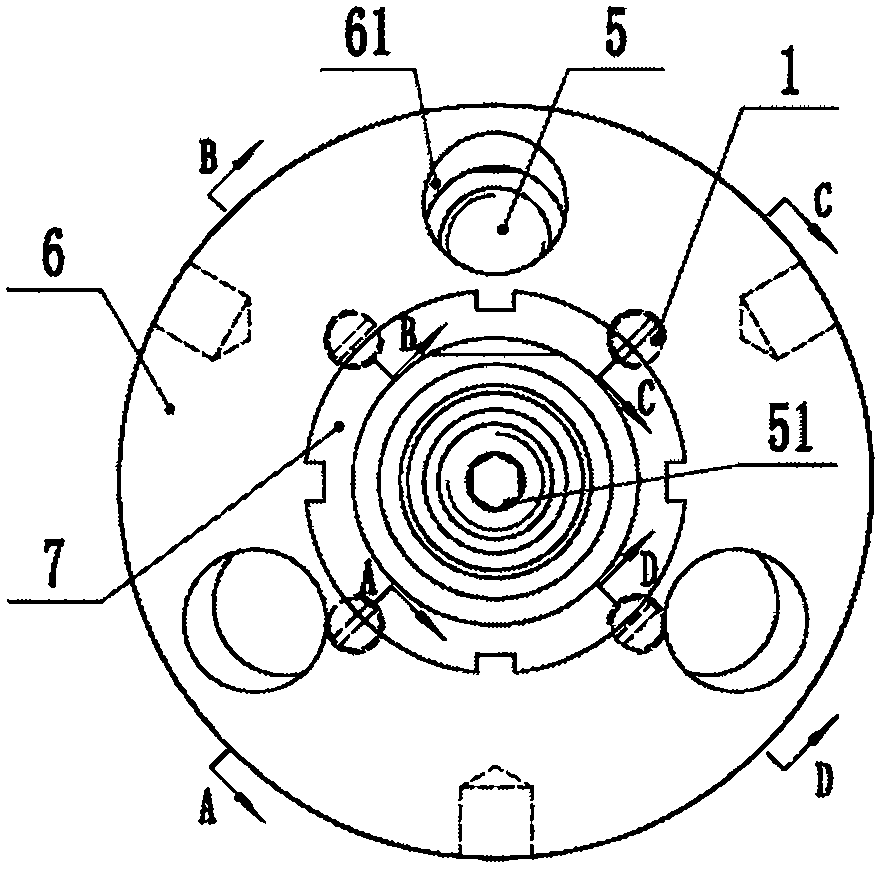

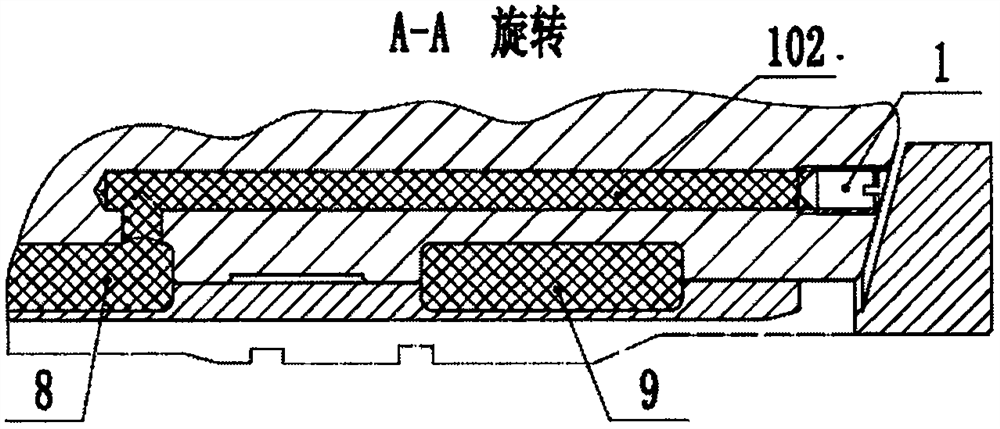

[0024] Attached below Figure 1-6 The technical solution provided by the present invention is described in more detail.

[0025] Such as figure 1 with figure 2 As shown, it is a mandrel for a static pressure cylindrical grinder used for processing thin-walled long-axis parts of the present application, which is installed on the main shaft of a common ordinary cylindrical grinding lathe and can be used to process thin-walled long-axis parts , its technical solutions mainly include:

[0026] The tensioning assembly realizes the axial clamping and clamping of the workpiece: specifically, the assembly includes the mandrel (2) and the expansion sleeve (3), and a left connection for connecting the spindle of the cylindrical grinding machine is provided in the axial direction of the mandrel (2) The hole (11) and the right connecting hole (12) are provided with a recessed platform on the circumference of the left end of the mandrel (2) for convenient placement and fixing of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com