A kind of injection molding hot runner system

A hot runner and uniform technology, applied in the field of uniform injection molding hot runner system, can solve the problems of difficult maintenance, high cost, and inability to guarantee, and achieve the effect of increasing heat preservation effect, increasing connection strength, and increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

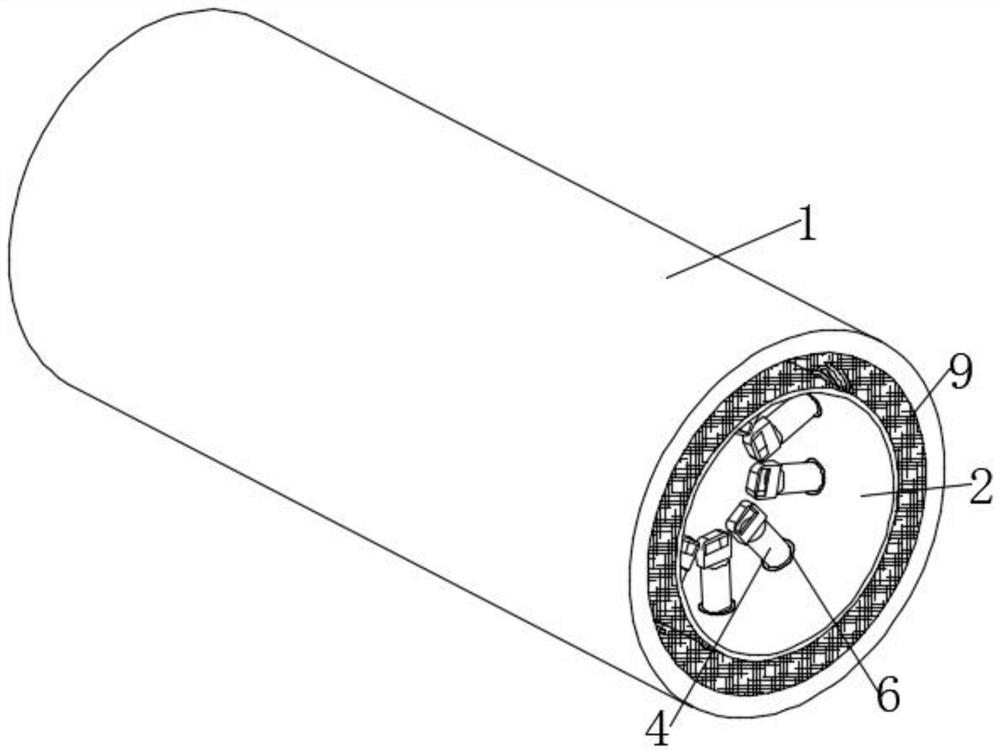

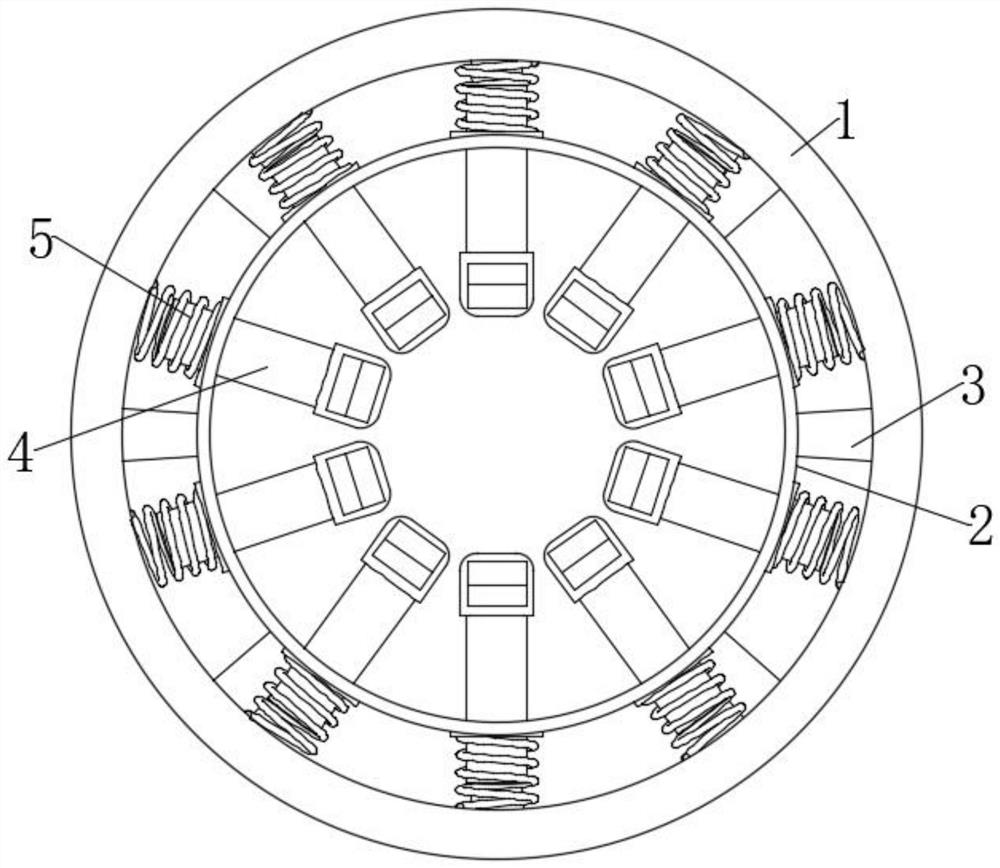

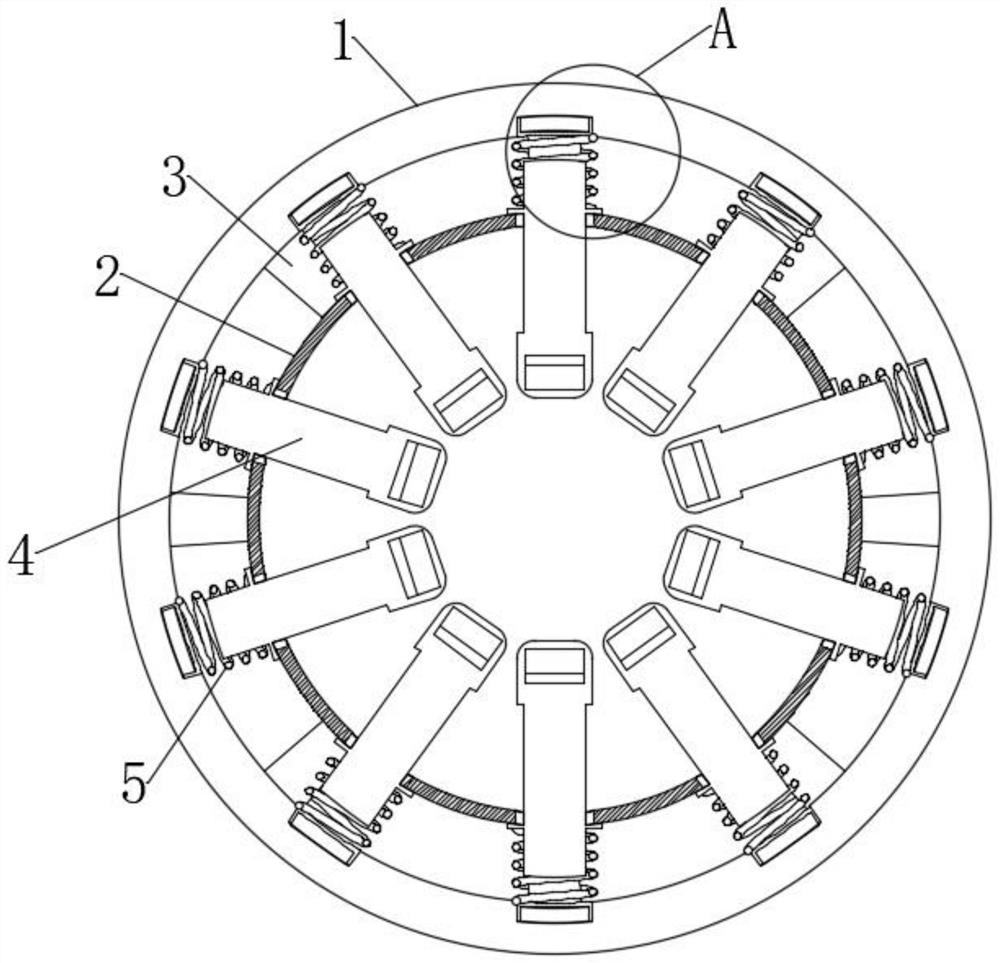

[0029] as attached Figure 1-5 A uniform injection molding hot runner system of the present invention as shown includes a material conveying pipe 2, which is used for conveying injection molding materials, and a sleeve 1 is sleeved on the outer side of the material conveying pipe 2. The sleeve 1 There are multiple groups of connecting columns 3 fixedly connected with the feeding pipe 2, and a plurality of adaptive regulators 4 are arranged in the feeding pipe 2. The adaptive regulator 4 includes a movable rod 401, and one end of the movable rod 401 is fixedly connected with a receiving device. The force block 403, the force block 403 is drilled with a choke groove 404, the cross section of the choke groove 404 gradually decreases with the flow direction of the injection molding material, and the other end of the movable rod 401 penetrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com